ALMA BHU SMF/MMF

Our media filtration can be built as single-media filtration (SMF) and multi-media filtration (MMF). A wide range of particles can be removed thanks to the choice of filter materials.

System can be extended by using activated carbon as a filter medium to remove dissolved organic compounds and trace substances

Hydraulic output: 100 - 1,000 m³/h

Particle removal of max. 95 %

ALMA FIL

Flexible filtration system that can be used and combined as a gravel filter, activated carbon filter or ion exchanger.

With manual or automatic backwash as required

Corrosion-resistant pressure vessel made of GRP or stainless steel

Hydraulic capacity: 2 - 100 m³/d

ALMA FIL AK

Our modular filtration system is specially designed for the use of activated carbon media and enables the effective elimination of organic micropollutants, pharmaceutical residues, AOX and other trace substances from process and wastewater.

With manual or automatic backwash as required

Corrosion-resistant pressure vessel made of GRP or stainless steel

Hydraulic capacity: 2 - 100 m³/d

ALMA ION

Ion exchange systems and ion exchange resins for the post-treatment of wastewater containing heavy metals, the treatment of water-bearing circuits (cooling circuits, heating circuits) or for the production of demineralized water for various production processes.

As a DI cartridge or as a finishing stage for wastewater treatment plants

Pressure tanks made of PE, PVDF, GRP or stainless steel

Customized design with automatic regeneration stations

ALMA MEM MF/ UF

Customized microfiltration and ultrafiltration systems as pre-treatment for water recycling or for the provision of process water. Can be designed for cross-flow or dead-end operation.

Depending on the wastewater composition and task, made of ceramic or organic membranes

Customized design according to preliminary tests and customer specifications

Hydraulic output: 1 - 50 m³/h

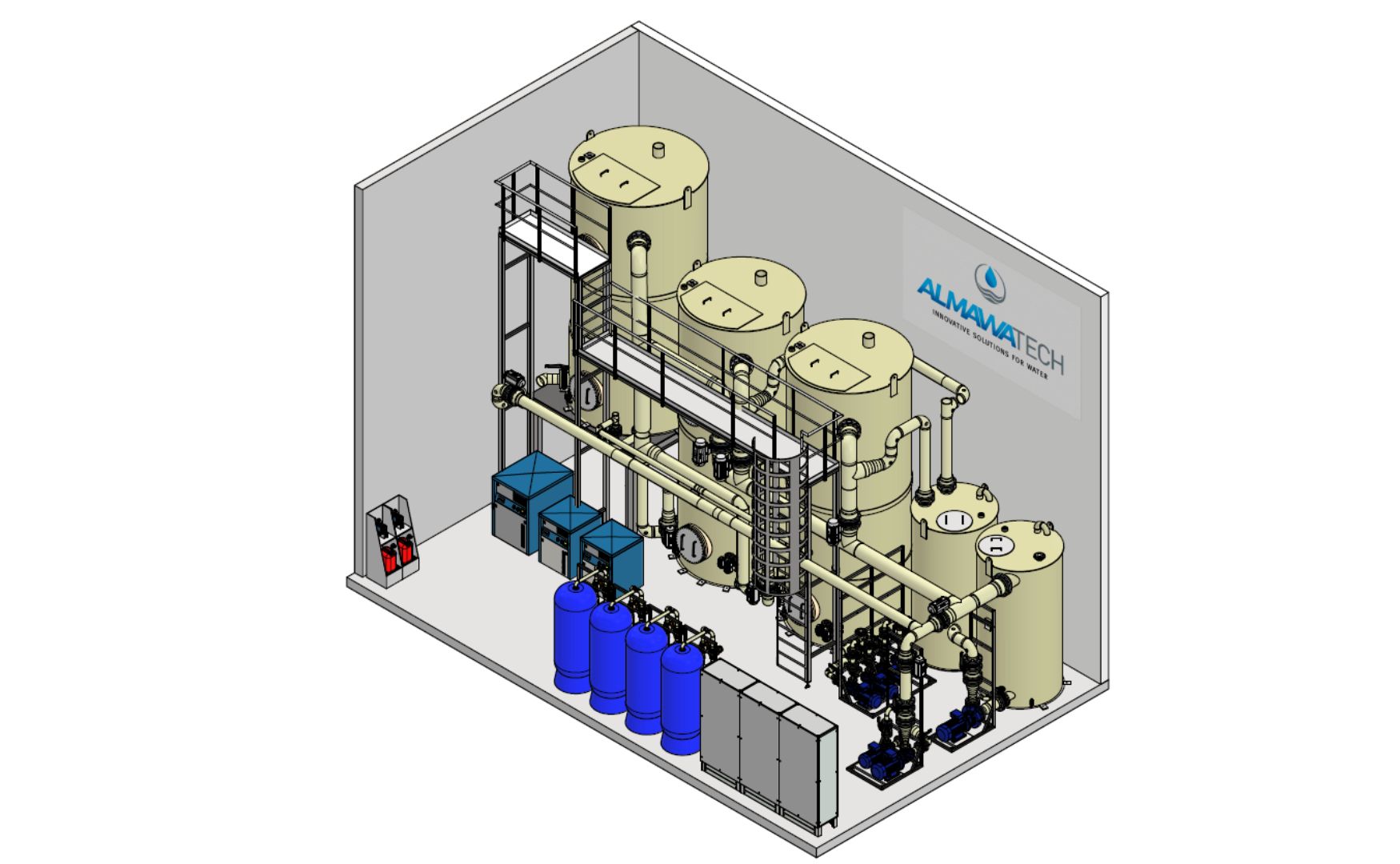

ALMA BHU BiosS-Treat

Combination system consisting of a precipitation and flocculation stage, biologically activated filtration and a reverse osmosis system for the production of ultrapure water from surface water or water reuse applications.

Reverse osmosis system with effective, biological pre-treatment

Hydraulic output: 100 - 3,000 m³/h

Cost-efficient pretreatment for reverse osmosis as an alternative to ultrafiltration

ALMA OSMO VE

Our fully automatic reverse osmosis system is specially designed for the production of demineralized water and ultrapure water. The system can be extended with a softening unit if required - for higher yields and longer membrane service life.

For particularly high water qualities, the system can be optionally equipped with a polishing stage - e.g. via ion exchangers or an EDI unit (electroion demineralization).

For the provision of high-purity demineralized water for various production processes

Reliable operation even with high SDI values

Hydraulic output: 1 - 50 m³/h

ALMA OSMO Process

Industrial reverse osmosis system installed on a stainless steel rack.

Fully automatic complete solution, if required with integrated softening system and upstream ultrafiltration for optimum operating conditions and long service life.

Ideally suited for the recovery of process water and the use of treated waste water in industrial water recycling and circulation systems.

High permeate yield due to the multi-stage design

Hydraulic output: 1 - 50 m³/h

Incl. softening system and ultrafiltration for pre-treatment, if required also dosing station for antiscalant and membrane cleaner

ALMA BHU BAF

Compared to conventional activated sludge systems, our biologically active filtration (BAF) requires only < 50 % of the space and can be equipped with denitrification if required.

Cleaning efficiency of max. 95 % with regard to organic compounds and max. 90 % with regard to nitrogen compounds

Hydraulic output: 100 - 1,000 m³/h

Can be used for both biodegradable wastewater and surface water

ALMA BioFil Compact

Our biofiltration enables the biodegradation of carbon and nitrogen compounds as an effective pre-treatment for water circuits. This pre-treatment significantly reduces operating costs when the water is further used as process water. The system includes carbon elimination, nitrification and denitrification.

Biofiltration for the treatment of water circuits or permeates

Hydraulic output: 10 - 50 m³/h

As pre-treatment for reverse osmosis systems (water recycling) or process water treatment for cooling circuits and heating networks

Get in touch with us!