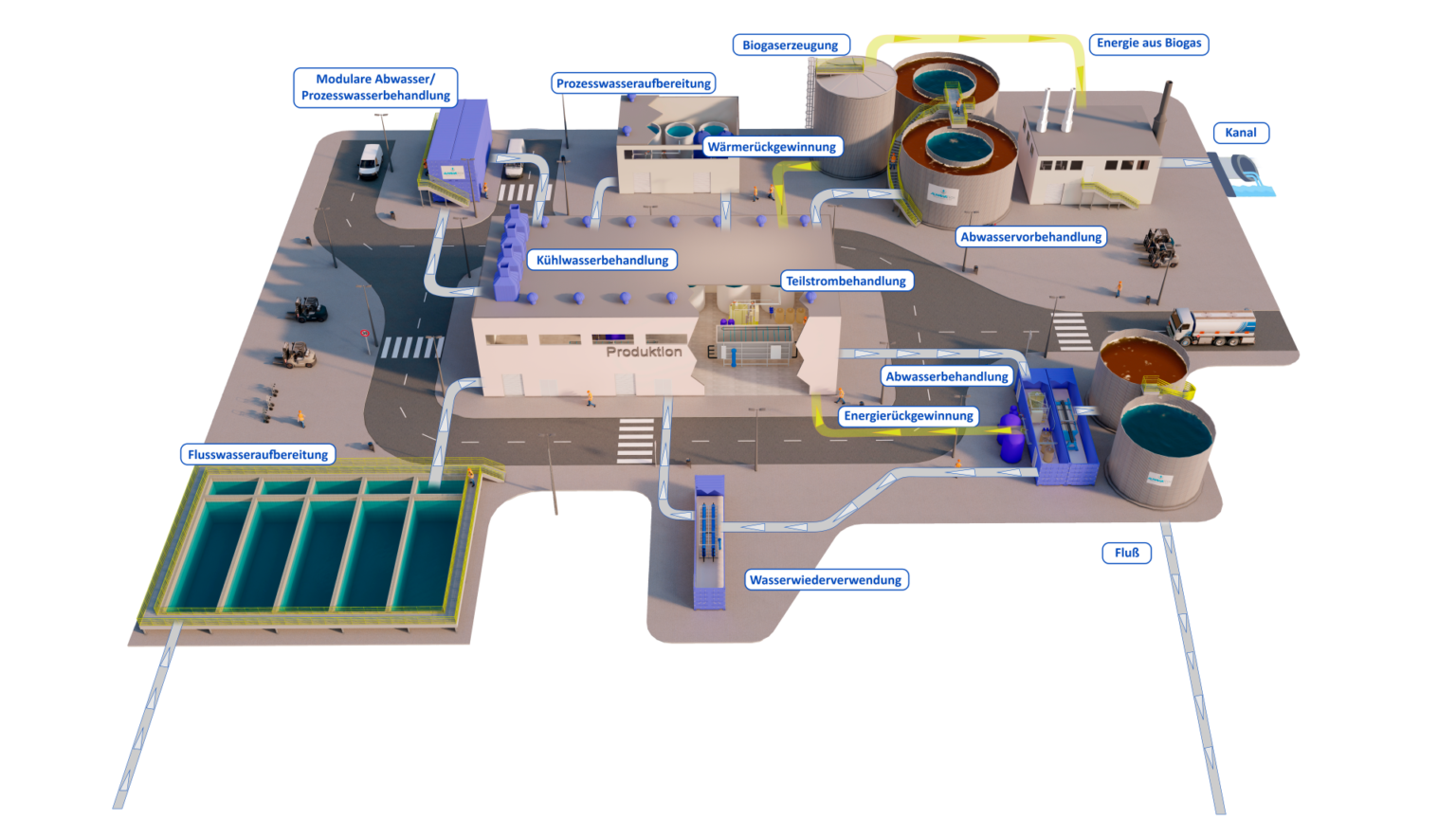

Plant engineering, process additives & operations management

We offer support throughout the entire project

Inventory analysis

Project development

Construction & Building

Plant management

Process additives

Planning & consulting

Who we are

Project closures

Qualified employees

Our extensive references cover a wide range of industries

Dairy Southern Germany, ALMA BioFil Compact

Vapor water treatment using biofiltration with a capacity of 600m3/d for a dairy in southern Germany. The vapor condensate is produced during the production of whey and lactose powder.

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

3M, Germany, ALMA OSMO Process

Construction of a multi-stage pilot membrane plant for the removal of per- and polyfluorinated chemicals (PFAS) from wastewater with a hydraulic capacity of 1 m³/h for the company 3M.

REMONDIS Industrie Service, ALMA Chem MCW

A CP batch plant (ALMA CHEM MCW) with cyanide decontamination and gravel filtration for REMONDIS Industrie Service in Leuna.

Viterra, Magdeburg, ALMA NeoDAF HDED, ALMA FLOC AC

A wastewater treatment plant for production wastewater from biodiesel production with a capacity of 650 m³/d for the company Viterra Magdeburg GmbH.

TU Kaiserslautern, ALMA BIO, FENTON, UV, AK

Customized research plant in container design with coarse filtration, biological treatment, ultrafiltration, activated carbon filter, ozonation, hydrogen peroxide dosing and UV treatment for the TU Kaiserslautern.

German Aerospace Center, Germany, ALMA OSMO VE

Production of 750 liters of ultrapure water per day by means of softening, reverse osmosis and UV treatment from seawater for the German Aerospace Center (DLR).

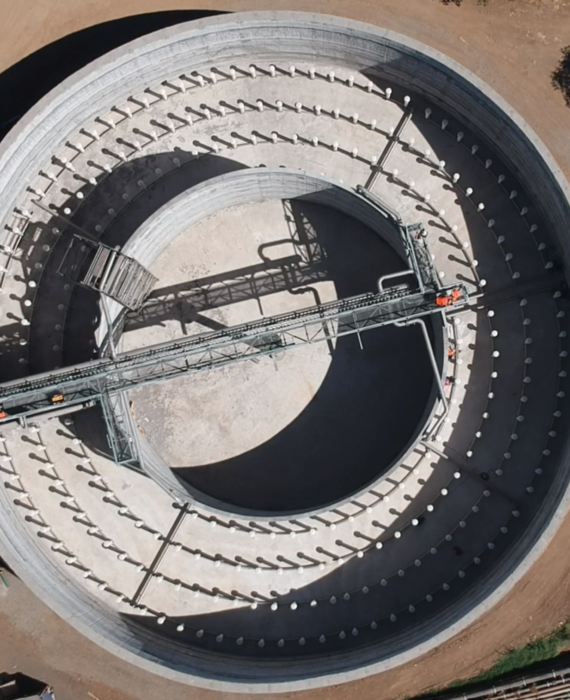

Focsani wastewater treatment plant, Romania, wastewater treatment and biogas plant

Turnkey construction of a municipal wastewater treatment plant with biogas plant as sludge treatment for a total wastewater volume of 40,000 m³/d in Romania.

Top Harvest Yanchang Coal, China, ALMA BHU LHPS, BAF, DAF

A wastewater treatment plant with a water recovery rate of 70% for 1,500 m³/h of refinery wastewater in China.

Sotravic Ltée, Mauritius, ALMA BHU LHPS

A drinking water treatment plant for surface water from various sources with a capacity of 3,333 m³/h. Realized with the combination of the ALMA BHU LHPS and the ALMA BHU MMF process for the company Sotravic Ltée on Mauritius.

Südzucker Zeitz PWT

A river water treatment plant with a capacity of 220 m³/h using the ALMA BiosS-Treat processfor Südzucker AG at the Zeitz site.

Abraham Benelux S.A., Belgium, ALMA BIO Kompakt

A compact aerobic treatment stage (ALMA BIO Compact) with sludge separation in the ALMA MODULE for wastewater from the ham smokehouse of Abraham Benelux S.A.

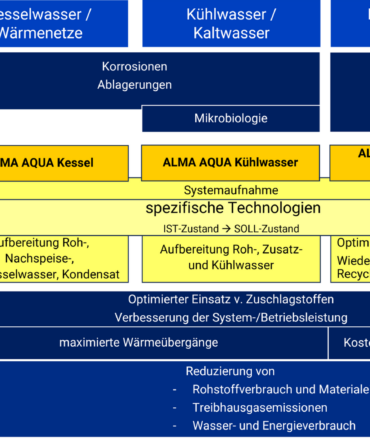

We also manufacture water treatment additives for waste water applications, membrane systems, cooling water circuits and boiler systems.

News from industrial water technology

ALMAWATECH at the Endress+Hauser Darmstadt Water Day

Review of our 3rd Industrial Water Day at ALMAWATECH - a complete success

WHG-compliant storage tanks for neutralizing and precipitating agents: safe, economical and well thought-out

Master's thesis on optimizing the ALMA NeoDAF dissolved air flotation system at ALMAWATECH - Investigation into improving air bubble generation in flotation systems

From old stock to modern wastewater system - Interview with engineer Tobias Höfer about MÖLLER Medical's new wastewater treatment system

Wastewater treatment in the metal industry - how CP systems solve the challenges

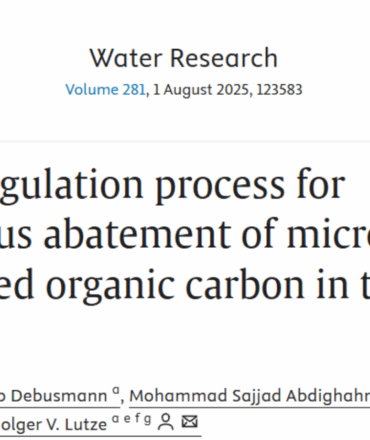

Patented ALMAWATECH process for Fenton flocculation at neutral pH presented in Water Research

High TOC in wastewater: challenges for reverse osmosis and water recycling plants