ALMA BHU GMR

Our ALMA BHU gas mixing reactor (GMR) has been developed for the production of biogas from biodegradable wastewater. Thanks to its special design, the reactor is also suitable for wastewater with high calcium concentrations.

Including downstream sedimentation tank with biomass recirculation

Hydraulic output: 50 - 250 m³/h

Made of enamel or stainless steel depending on size

ALMA BHU BIO EGSB

The ALMA BHU BIO EGSB (Expanded Granular Sludge Bed) reactor is a two-stage biogas reactor that requires only half the space of UASB reactors.

If required, with external separator system from Almawatech for biomass recirculation

Reactor size: 350 - 1,000 m³

Stainless steel tank construction welded or bolted

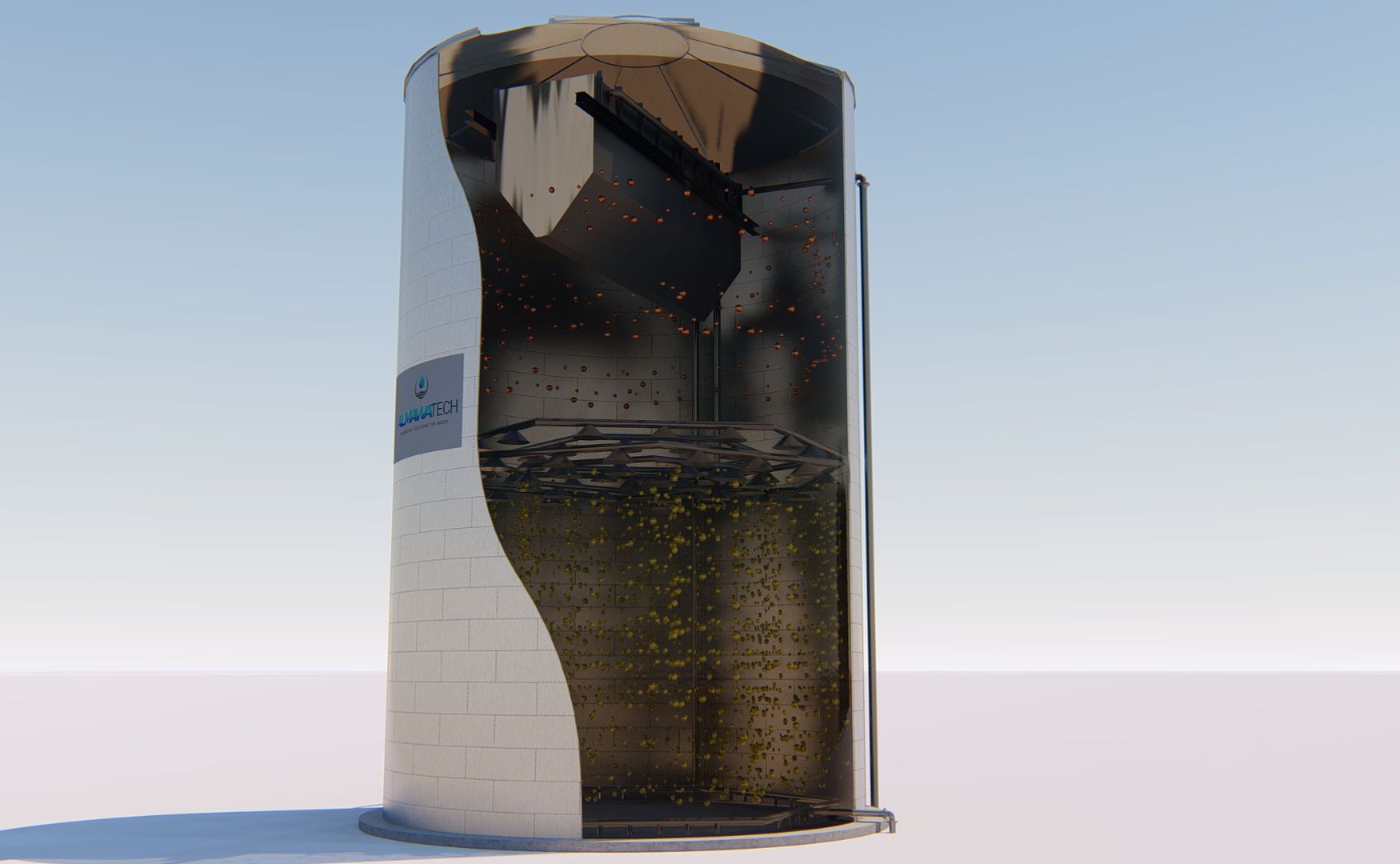

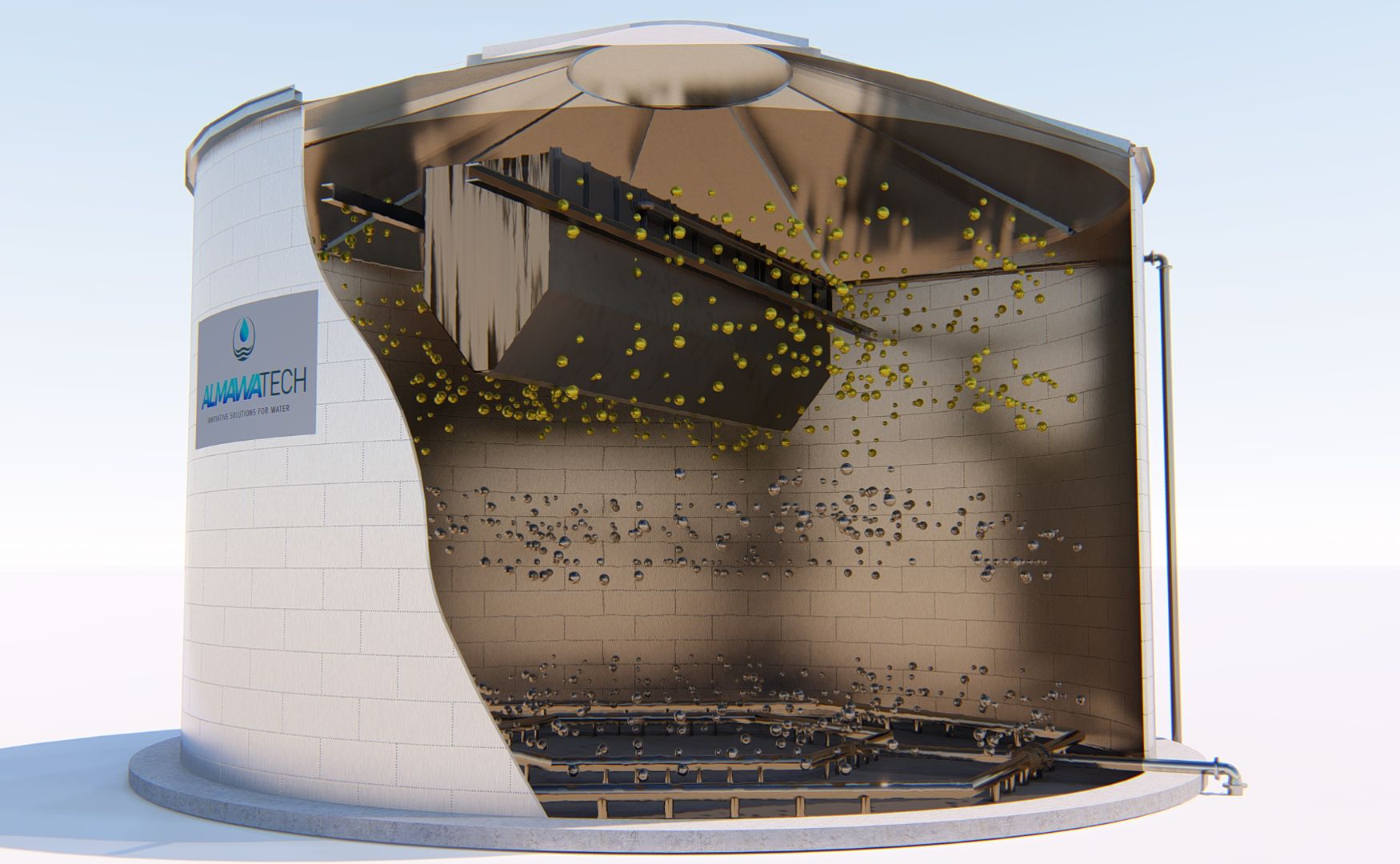

ALMA BIO UASB

The ALMA BIO UASB (Upflow Anaerobic Sludge Blanket) is a robust single-stage reactor with external biomass recirculation and is an extremely effective solution for wastewater from the food industry.

With integrated 3-phase separator for effective separation of the biogas

Reactor size: 50 - 3,000 m³

Optionally made of welded or bolted stainless steel

ALMA BIOMAGE

The biogas plant with post-treatment was specially designed for the treatment of whey and waste water from the milk processing industry.

Control and dosing stations can be installed in the ALMA module at the customer's request

High biogas production of 0.5 - 0.7 m³/kg COD

If required, with post-treatment from aerobic, biological stage, phosphate precipitation, gas scrubbing, desulphurization and gas pressure increase

Your experts for biogas plants