Task

Bäckerei Betz, a traditional Ulm bakery, is now run by the 5th generation of the Betz family. The tasty bakery products are sold in over 40 specialist stores in Ulm and the surrounding area.

Our task was to build a wastewater treatment plant to treat production and cleaning wastewater for indirect discharge into the sewer.

Design data

Preparation quantity:

- 25m3/d

Target parameters:

- Reduction COD > 80 %

- pH-neutral drain

Solution & implementation

Our advanced process for reducing the COD concentration in bakery wastewater containing fat is characterized by three key process steps.

1. class NS 7 grease separator: The first step was to install a class NS 7 grease separator with a sludge trap. This step enables the efficient removal of grease and oil from the wastewater.

2. homogenization in the stacking tank: In the second process step, the pre-treated wastewater is transferred to a stacking tank where it is homogenized. This equalizes the different composition of the wastewater from production and ensures a uniform process.

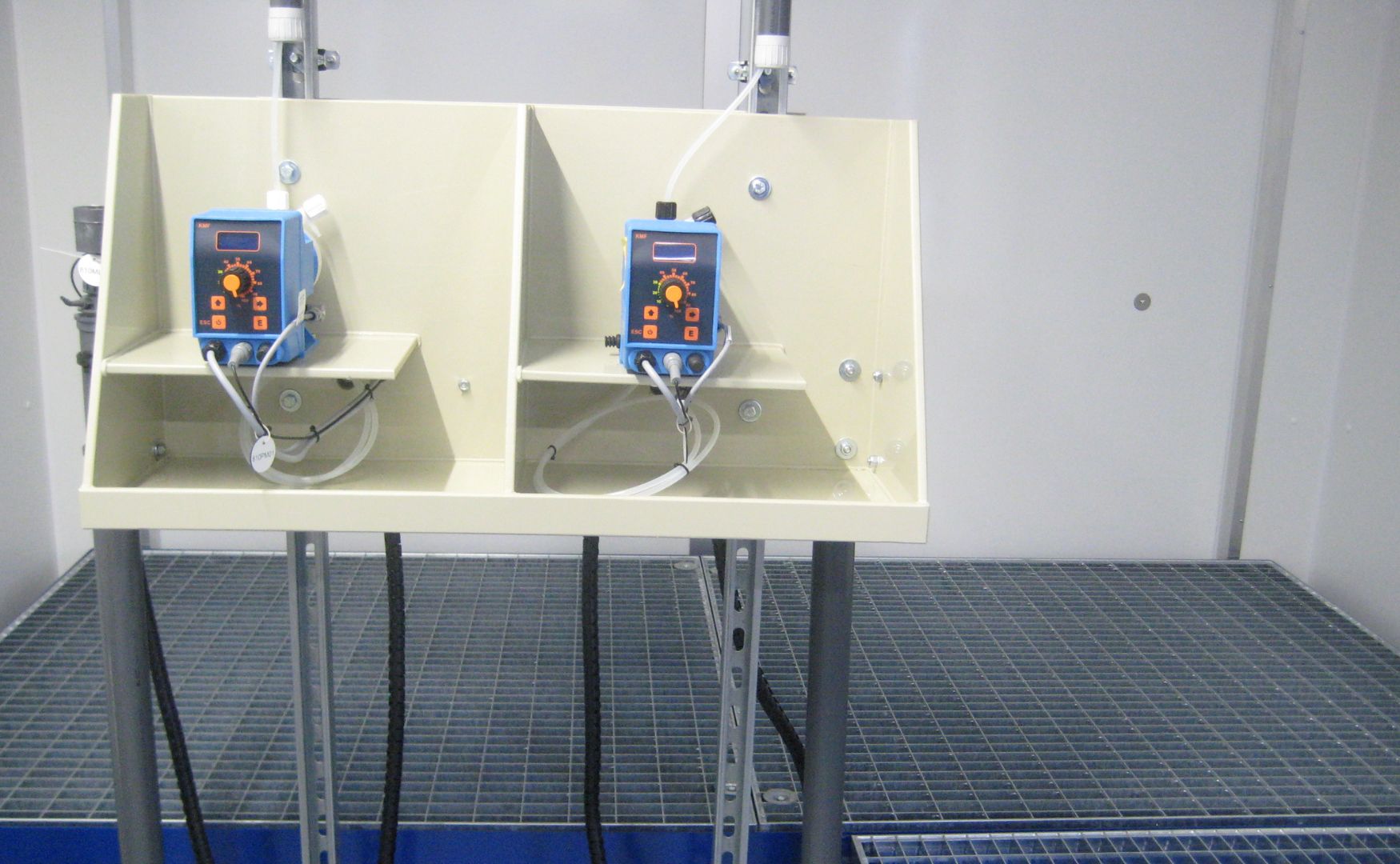

3. ALMA NeoDAF flotation plant: In the third step, the wastewater enters our ALMA NeoDAF Blue flotation plant. In this flotation plant, precipitants, flocculants and neutralizing agents are added(ALMA FLOC M). A pH-controlled process converts dissolved organic compounds into insoluble compounds and separates them from the wastewater. The flotation system is integrated into an ALMA module.

References food industry

Precipitation + flocculation,

Neutralization

ALMA FLOC M,

ALMA module

Similar projects

Dairy Southern Germany, ALMA BioFil Compact

Vapor water treatment using biofiltration with a capacity of 600m3/d for a dairy in southern Germany. The vapor condensate is produced during the production of whey and lactose powder.

Eisbär Eis GmbH, Germany, ALMA NeoDAF HDED

We had the opportunity to supply and install our ALMA NeoDAF flotation system with a capacity of 16 m³/h as part of the construction of a new wastewater treatment plant for an ice cream manufacturer in northern Germany.

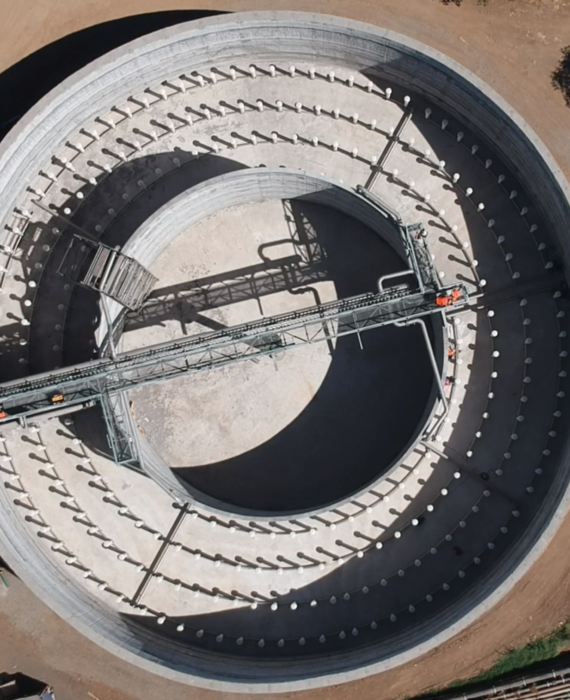

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Sternquell Brauerei GmbH, ALMA Neutra

Treatment of 360m3 of brewery wastewater per day with a pump shaft, solids separator and a neutralization system for Sternquell Brauerei GmbH.

Bäckerei Betz GmbH, Germany, ALMA NeoDAF Blue, grease separator

Treatment of 25m3 of bakery wastewater per day in a grease separator and a flotation plant for Bäckerei Betz GmbH.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Schweizer Zucker AG, Switzerland, degasser

A deaerator for a biogas plant between the lime separator and circular clarifier for Schweizer Zucker AG at the Frauenfeld site in Switzerland.

Südzucker AG, Belgium, ALMA BHU BiosS-Treat

A river water treatment plant (2 x 275 m³/h) for the production of process water, cooling water and boiler feed water in drinking water quality with reverse osmosis system and ion exchangers for the company Südzucker AG at the Wanze site in Belgium.