Task

Molkerei Niesky GmbH, located near the Polish border, specializes in the production of a wide range of high-quality cheeses. The product range includes Edam, Gouda, Emmental, mozzarella, cagliata and a variety of other first-class cheese products.

Due to the naturally high pH value of the whey produced during our production processes, careful neutralization of the waste water is essential.

Design data

The wastewater to be treated consists of rinsing water from cheese production and has a pH value in the alkaline range.

Waste water volume:

- max. 700 m³/d

Target parameters:

- Neutralization of the pH value

- Intermediate storage with biodegradation

Solution & implementation

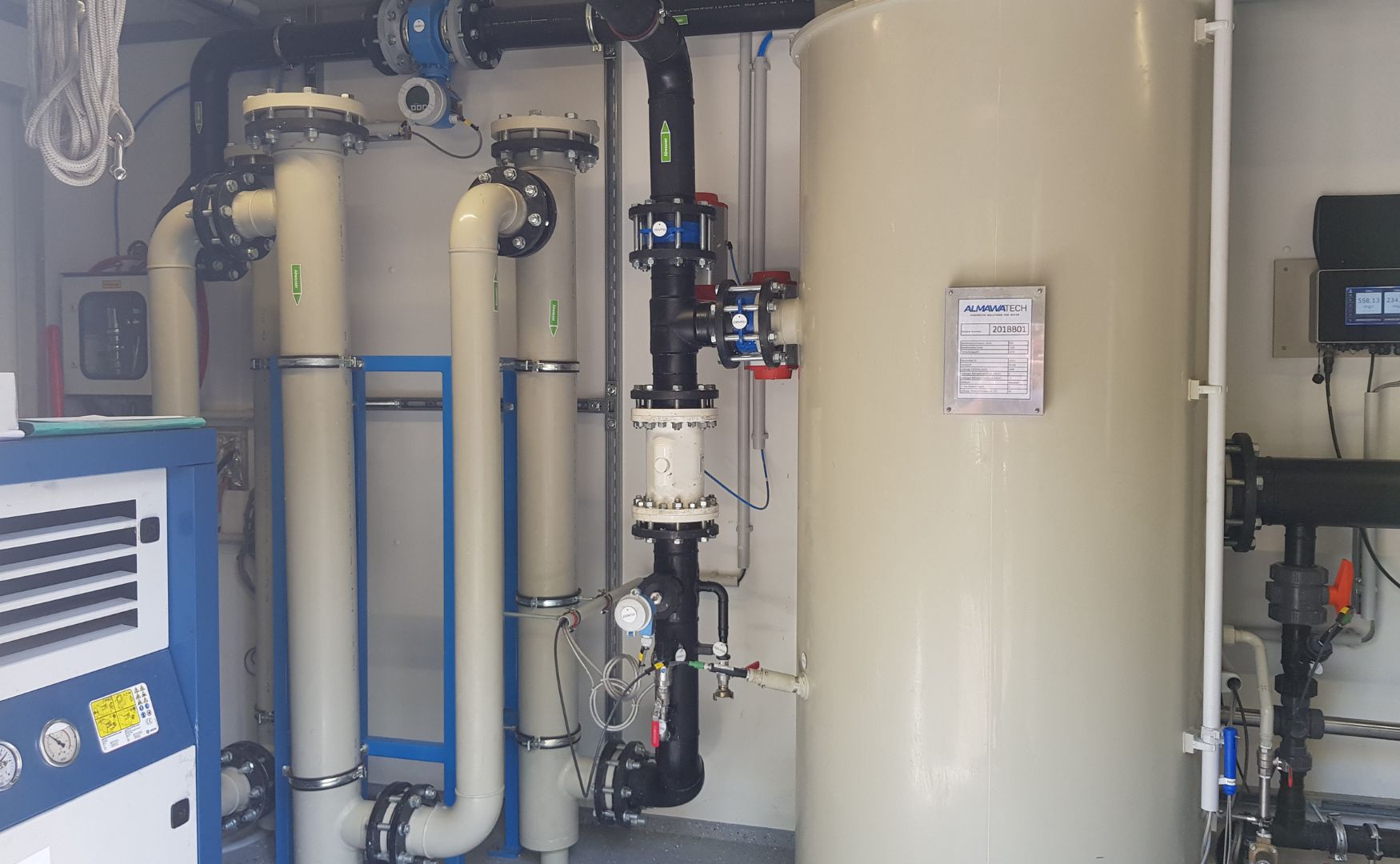

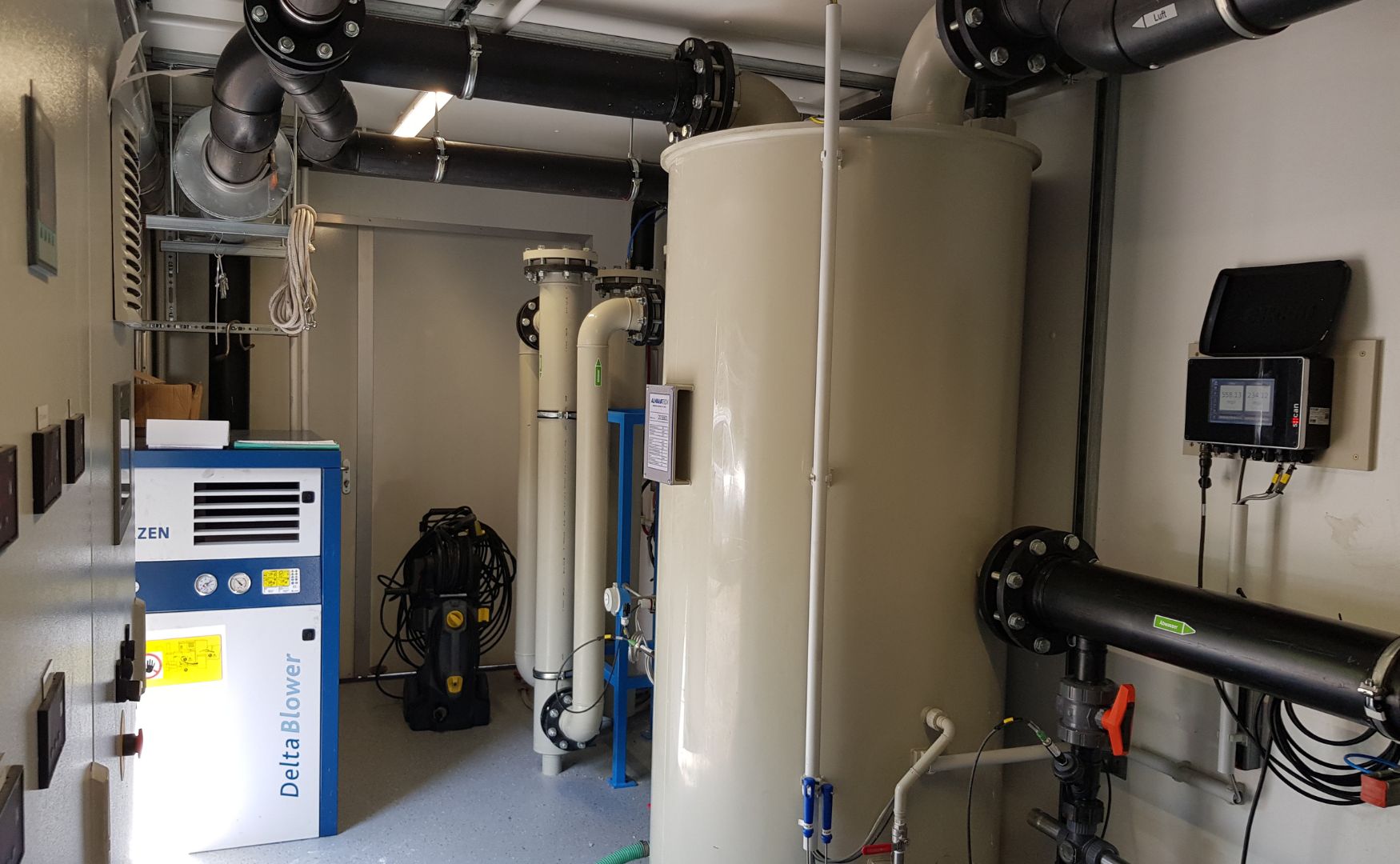

We have built a 700 m³ mixing and equalization tank (MAB) for efficient intermediate storage of the rinsing water from our production facility. This tank is filled by a powerful double pumping station. The MAB is continuously aerated and is always half-filled with wastewater. This measure promotes the colonization of aerobic microorganisms, which effectively break down a considerable proportion of the organic compounds.

Due to the naturally high pH value of the whey waste water, we have integrated a two-stage CO₂ neutralization system into an ALMA module. In this system, the pH value is automatically and precisely reduced to a neutral level.

References cheese dairies & dairies

CO₂ neutralization

ALMA module

Similar projects

Dairy Southern Germany, ALMA BioFil Compact

Vapor water treatment using biofiltration with a capacity of 600m3/d for a dairy in southern Germany. The vapor condensate is produced during the production of whey and lactose powder.

Molkerei Niesky GmbH, Germany, ALMA module

A combination of an aerated mixing and equalization tank with downstream CO₂ neutralization installed in the ALMA module for Molkerei Niesky GmbH.

Municipality of Neuenkirchen / Naarmann private dairy, Germany, ALMA NeoDAF HDED

A dissolved air flotation plant (ALMA NeoDAF 40.000 in stainless steel) for the treatment of whey wastewater as pre-treatment for the Düsterbach municipal sewage treatment plant.

Vogtlandmilch GmbH, Germany, ALMA Neutra

A grease separator with a neutralization system (ALMA Neutra) installed in the ALMA module for Vogtlandmilch GmbH.