Aerobic treatment is a biological process in which organic impurities in water or wastewater are broken down by microorganisms using oxygen (O₂). This form of water and wastewater treatment is used in many industrial applications as it is efficient and environmentally friendly. Microorganisms oxidize the organic substances and convert them into harmless products such as carbon dioxide (CO₂) and water (H₂O). Aerobic treatment processes play a central role in industrial wastewater treatment, as they enable a high degradation rate of pollutants.

Table of contents

Technical background

Aerobic treatment requires a constant supply of oxygen, which is provided in the form of dissolved oxygen in the water. This is done by mechanical aeration systems such as bubble aerators, surface aerators or other oxygen supply mechanisms. The microorganisms use the oxygen as an electron acceptor in the degradation of organic compounds, which initiates the process of biological oxidation.

Applications of aerobic processes in practice

1. activation process

In aeration tanks, the wastewater is mixed with microorganisms and oxygen. These microorganisms decompose the organic impurities and purify the wastewater. The activated sludge process is one of the most widely used technologies for biological wastewater treatment in municipal and industrial wastewater treatment plants.

Photo: Aeration tank from our ALMA BHU BIO

2. trickling filter

A trickling filter uses a solid, aerated surface on which microorganisms grow. The wastewater trickles over this surface and the microorganisms decompose the organic contaminants, while oxygen is supplied by natural air circulation or additional aeration.

3. membrane bioreactors (MBR)

MBR plants combine biological aerobic treatment with membrane filtration. The microorganisms break down organic substances while the membranes retain solid particles and microorganisms. This technology is used in industrial wastewater treatment, particularly where high water quality requirements apply.

Photo: Compact membrane bioreactor(ALMA BIO MBR) in modular container design(ALMA MODUL)

4. biologically activated filtration - ALMA BHU BAF and ALMA BioFil Compact

Biologically activated filtration is a special form of aerobic water treatment in which small residual loads of organic substances are removed from large water flows. The ALMA BHU BAF-technology was developed for water flows of up to 1,000 m³/h, while ALMA BioFil Compact is suitable for wastewater flows of up to 50 m³/h. These technologies are primarily used for the treatment of vapor condensates in the food industry, especially in dairies. They make it possible to remove residual contamination that could otherwise lead to biofouling in reverse osmosis systems. By reducing residual contamination, water recycling is facilitated and the economical operation of reverse osmosis systems is supported.

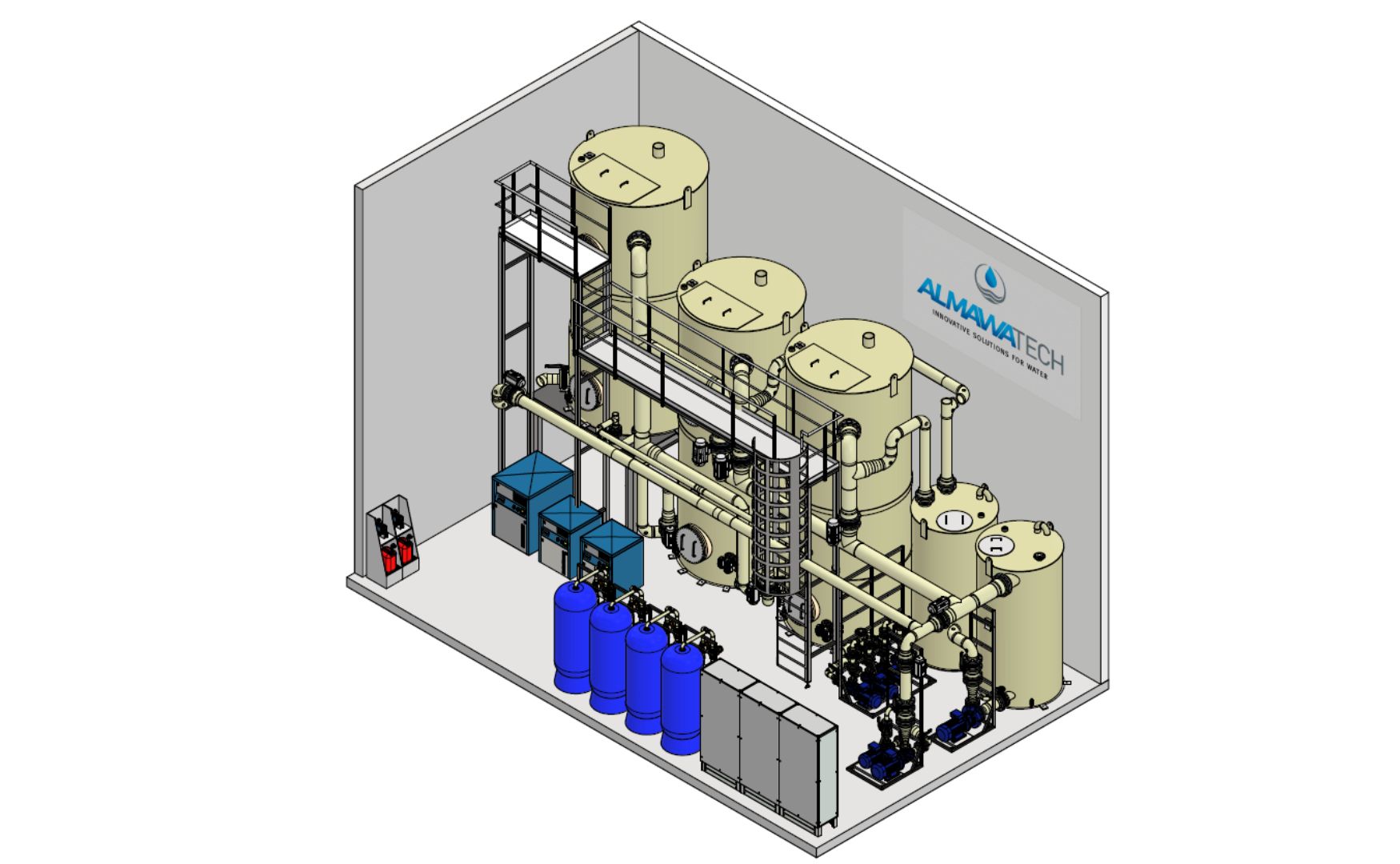

Photo: 3D construction of our ALMA BioFil Compact with carbon degradation, nitrification and denitrification

Factors influencing aerobic processes

oxygen content:

- The oxygen content in the water must be sufficiently high to ensure microbial decomposition. A content of 1.5 to 2 mg/L is ideal for many systems.

Temperature and pH value:

- Optimum temperatures are between 20 °C and 35 °C, while the pH value should be between 6.5 and 8.5.

Nutrients:

- Microorganisms require a sufficient supply of nitrogen and phosphorus to maintain the decomposition process.

Advantages and challenges

Advantages:

- Effective removal of organic impurities.

- Environmentally friendly technology through the use of natural microbial processes.

- Flexible and scalable for different applications.

Challenges:

- High energy requirement for ventilation.

- Regular sludge treatment and removal required.

Conclusion

Aerobic treatment is a key technology in industrial water and wastewater treatment based on natural microbial degradation processes. Technologies such as the classic membrane bioreactor(ALMA BIO MBR) or our biofiltration ALMA BHU BAF and ALMA BioFil Compact enable particularly efficient treatment of low residual loads, which improves water quality and makes the operation of reverse osmosis systems economical in the context of water recycling.

For further information on our products, please feel free to contact us at any time!