Corrosion inhibitors are essential chemical substances that are used to slow down or completely prevent corrosion processes in water-bearing systems. They protect metal surfaces from the aggressive effects of corrosive media such as oxygen, chlorides or sulphuric acid. The use of inhibitors is crucial for extending the service life of systems and maintaining their efficiency.

Table of contents

Technical principles of corrosion

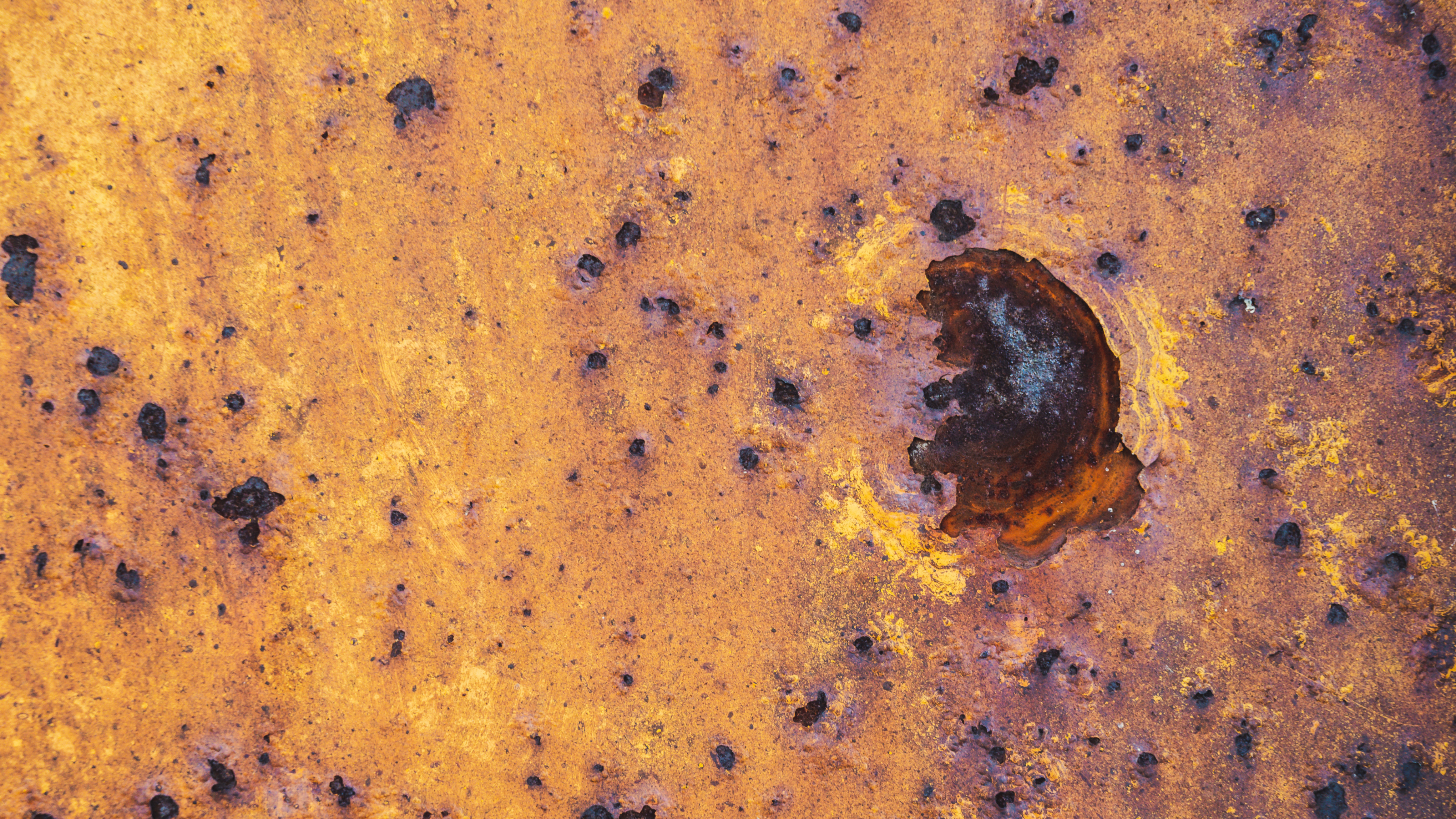

Corrosion is caused by electrochemical reactions between a metal and its environment. There are different types of corrosion:

- Surface corrosion: Uniform dissolution of the metal surface.

- Pitting: Localized corrosion spots that form deep holes.

- Crevice corrosion: Occurs in places where oxygen exchange is restricted, e.g. under seals.

- Stress corrosion: A combination of mechanical stress and corrosive attack.

These forms of corrosion can cause serious damage to pipes, heat exchangers, boilers and other water-bearing components.

Photo: Surface corrosion and pitting

Mode of action of corrosion protection inhibitors

Corrosion protection inhibitors work through various mechanisms:

1. anodic inhibitors

These substances form a passivating protective layer on the metal surface, which blocks the anodic reaction. Examples are phosphates and silicates.

2. cathodic inhibitors

They reduce the speed of the cathodic reaction, e.g. by inhibiting oxygen reduction. Frequently used substances are zinc salts and polyphosphates.

3. film-forming inhibitors

These are organic compounds that form a hydrophobic protective layer on the metal surface. This layer prevents direct contact between water and metal.

4. neutralizing inhibitors

These substances bind aggressive ions such as chloride or sulphate, which reduces the risk of corrosion.

Areas of application for corrosion protection inhibitors

Cooling water systems

In open or closed cooling circuits, inhibitors protect pipes and heat exchangers from oxygen corrosion and pitting. This increases the efficiency of heat transfer and reduces maintenance costs.Boiler water treatment

In boiler systems, inhibitors prevent deposits and corrosion damage to steam generators and pipes. Here, phosphate-based inhibitors are used specifically to stabilize the water chemistry in the boiler.Process water

In the chemical industry, inhibitors protect the complex pipe networks and reactors from corrosion damage that can be caused by aggressive media.

ALMAWATECH solutions: ALMA AQUA Boiler and ALMA AQUA Cooling Water

As a specialist in water treatment, ALMAWATECH offers customized corrosion protection solutions for cooling and boiler circuits. Our product lines ALMA AQUA Boiler and ALMA AQUA Cooling Water product lines include a wide range of corrosion protection inhibitors tailored to the specific requirements of various industries. Our products are Made in Germany and guarantee the highest quality and reliability.

Our inhibitors offer:

- Optimum protection against various types of corrosion.

- Improved system efficiency through minimized maintenance effort.

- Environmentally friendly formulations to comply with legal requirements.

Photo: Our Made in Germany equipment for boiler systems, hot water networks and cooling water treatment

Conclusion

Corrosion inhibitors are indispensable in industrial water treatment. They protect against costly corrosion damage, extend the service life of systems and improve operational safety. ALMAWATECH's customized solutions provide our customers with optimum results for cooling and boiler water applications.

For further information on our products, please feel free to contact us at any time!