Task

In an industrial production process, alkaline wastewater is produced that must be adjusted to the permitted pH value before being discharged into the wastewater system. An economical and sustainable solution is to be found that enables continuous neutralization and at the same time allows the use of used acids as neutralization agents.

The system must meet the following requirements:

- Reliable neutralization of wastewater to the officially specified limit values

- Automatic pH control for constant and safe process control

- Use of used acids to reduce operating costs and conserve resources

- Easy handling of chemicals for operating personnel

- Compact and safe integration of the system technology into the existing infrastructure

Design data

Preparation quantity:

- Maximum waste water volume 75m3/d

Target parameters:

- Neutralization of waste water to a pH value between 6.5 - 10.0

Solution & implementation

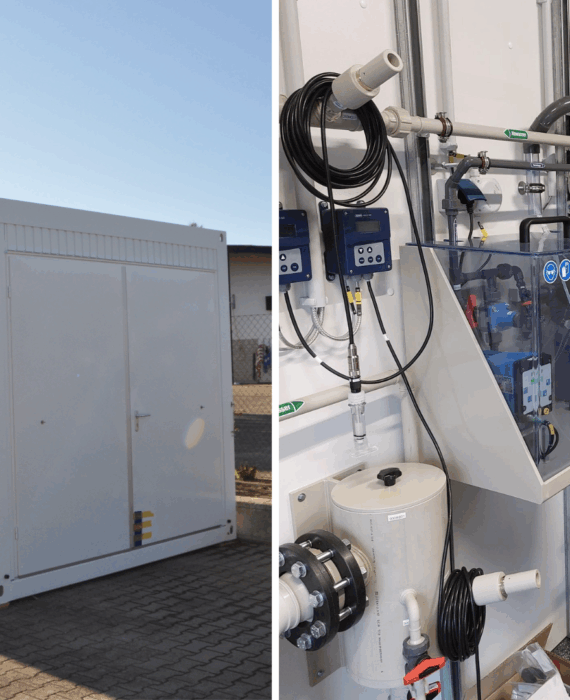

To implement the neutralization, the ALMA Neutra was installed, a system with fully automatic pH control and chemical neutralization through the targeted use of used acids. Neutralization takes place in a reaction loop with a static mixer, which ensures homogeneous mixing and precise adjustment of the pH value. The used acids are dosed via an IBC dosing station. The entire neutralization process is controlled by an automatic control system with pH measurement, so that the dosing is continuously adjusted to the actual wastewater composition.

The entire system technology is integrated in our ALMA modulea customized technical room container, which is equipped with a WHG-compliant drip tray. The module includes the complete switching and control technology, which enables fully automatic process control, as well as various safety devices to ensure reliable monitoring of neutralization and chemical handling.

An integrated roller shutter allows the IBC containers to be easily exchanged, making the handling of used acids considerably easier. The on-site stacking containers for the used acids are positioned outside the module, allowing flexible adaptation to the chemical requirements.

The entire automation of the process sequence is based on a programmable logic controller that is integrated in the Siemens TIA portal.

References Material recycling & disposal companies

Similar projects

Tobacco factory, Luxembourg, ALMA Neutra

ALMAWATECH implemented a compact neutralization plant in container design for a tobacco factory to treat 30 m³/day of acidic wastewater. The insulated and heated ALMA module has an agitated stacking tank for homogenization and a fully automatic, pH-controlled neutralization system that ensures stable operating conditions and standard-compliant discharge values.

Sternquell Brauerei GmbH, ALMA Neutra

Treatment of 360m3 of brewery wastewater per day with a pump shaft, solids separator and a neutralization system for Sternquell Brauerei GmbH.

Molkerei Niesky GmbH, Germany, ALMA module

A combination of an aerated mixing and equalization tank with downstream CO₂ neutralization installed in the ALMA module for Molkerei Niesky GmbH.

Vogtlandmilch GmbH, Germany, ALMA Neutra

A grease separator with a neutralization system (ALMA Neutra) installed in the ALMA module for Vogtlandmilch GmbH.