Biofiltration offers an effective way of pretreating organically contaminated wastewater so that it is optimally prepared for further treatment in reverse osmosis systems. Organic compounds and nitrogen are specifically broken down with the help of sessile microorganisms.

This pre-treatment significantly reduces biofouling on the membranes of the reverse osmosis systems. This not only improves the operational stability of the systems, but also enables water recycling to be implemented economically.

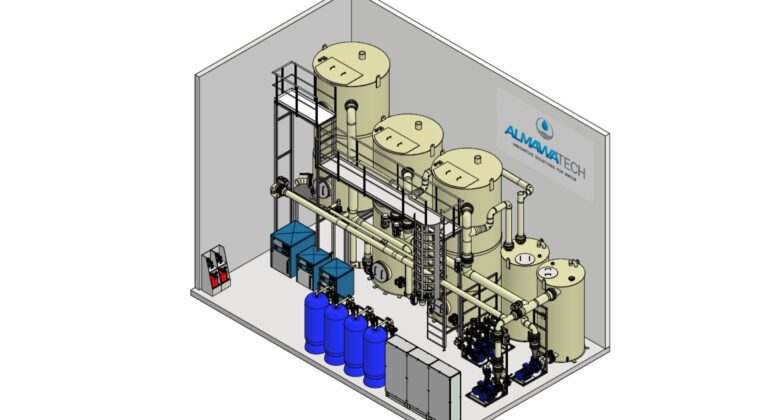

Our biofiltration systems, such as the ALMA BHU BAF and the ALMA BioFil Compact, are specially developed for the treatment of wastewater, process water and contaminated surface water and create optimum conditions for efficient water treatment and reuse.

Photo: 3D design of our compact biofiltration system ALMA BioFil Compact

Table of contents

Advantages of biofiltration

1. reduction of operating costs and energy requirements:

Biofiltration significantly reduces energy consumption and the need for operating resources, especially in membrane systems such as reverse osmosis. This is achieved through the effective removal of organic compounds and nitrogen, which prevents biofouling and rapid clogging of the membranes.

2. efficient removal of organic compounds:

By using clay beads as growth carriers for microorganisms, biofiltration can eliminate organic compounds (BOD, COD) down to very low concentration ranges. This microorganism community consists of highly specialized anoxic and aerobic microorganisms.

3. space saving and flexibility:

Compared to conventional activated sludge systems, biofiltration requires up to 50% less space. In addition, the modular design makes it easy to expand the water treatment capacity.

4. high elimination performance at low loads:

Even with low organic loads, such as in vapor condensate, biofiltration shows a high elimination performance.

Biofiltration applications

1. pre-treatment for water recycling (water reuse):

In practice, the COD concentration of many pre-treated wastewaters and process waters is 100 - 400 mg/l. Although this wastewater meets the criteria for economical water recycling, it requires further treatment. Biofiltration reduces the COD, TOC and nitrogen content, allowing the wastewater to be efficiently treated for reuse.

2. treatment of cooling water and vapor condensate

Dissolved organic compounds in cooling water and vapor condensates often lead to biofouling in reverse osmosis systems. Biofiltration offers an effective solution for reducing these dissolved organic substances. Biofiltration extends the service life of the membranes, increases the water reuse rate and significantly reduces operating costs.

3. pretreatment for reverse osmosis systems

The high COD, TOC and nitrogen content in wastewater leads to high operating costs for reverse osmosis systems due to biofouling and rapid membrane blockage. Biofiltration as pre-treatment significantly reduces these loads and optimizes the efficiency of reverse osmosis systems.

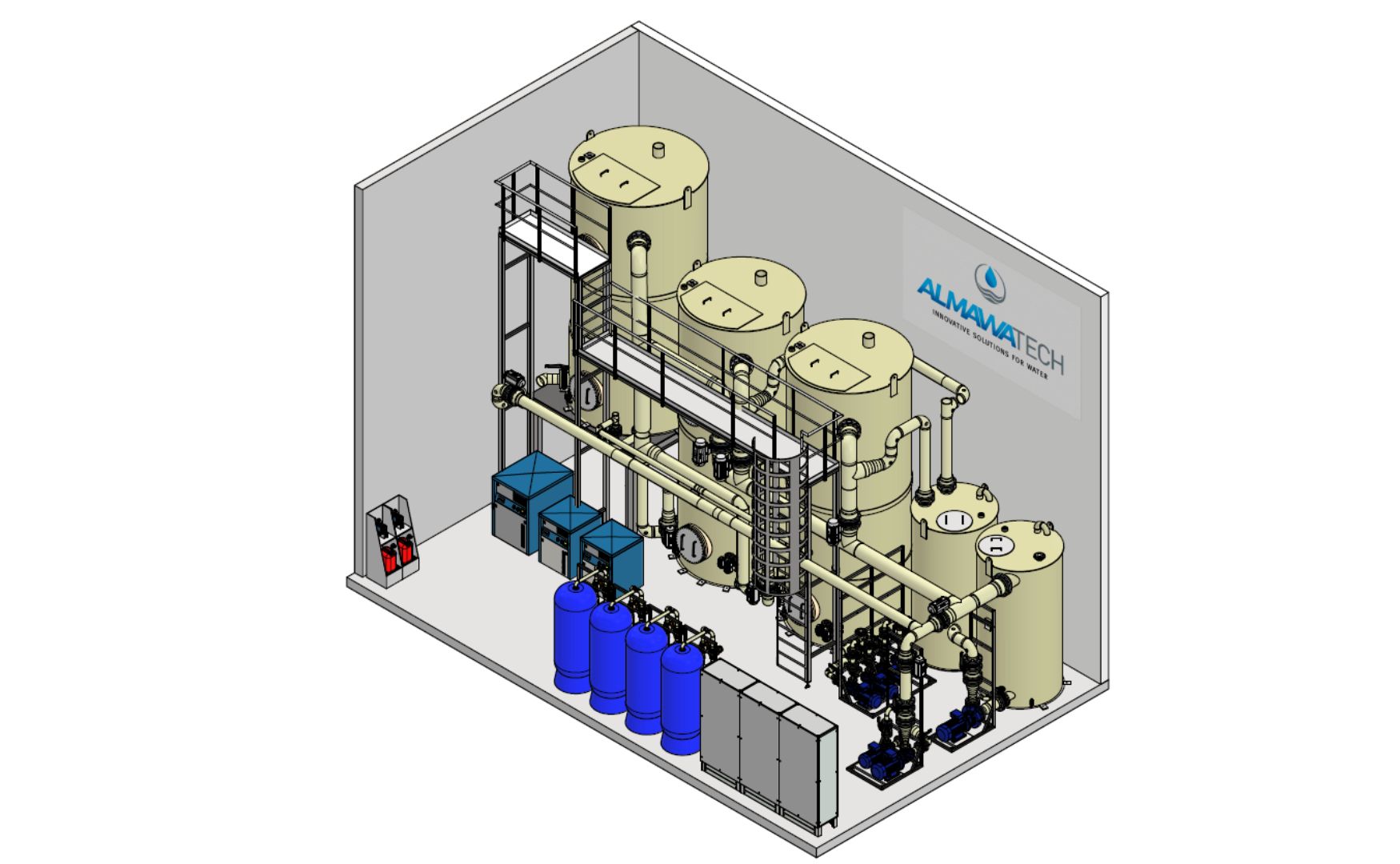

Photo: Our ALMA BHU BAF biofiltration system during backwashing to loosen up the filter bed

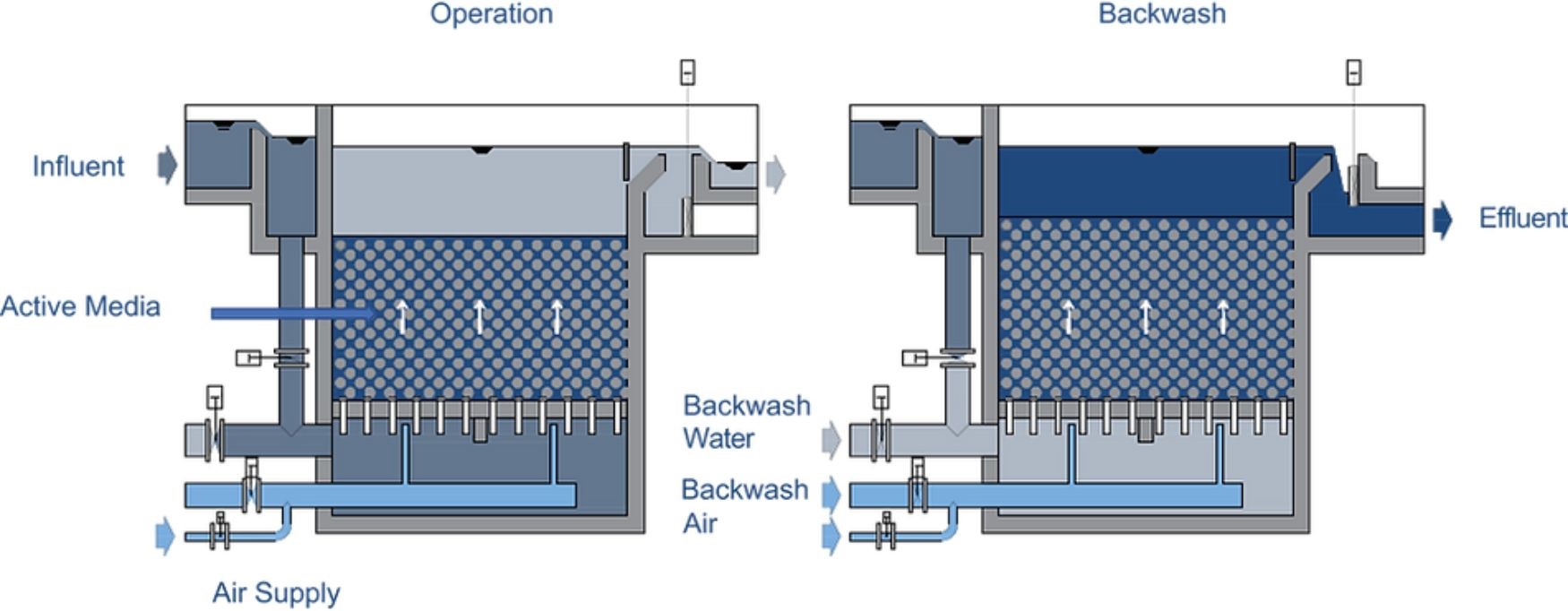

Technical implementation of biofiltration

BAF technology uses clay-based beads that enable the growth of various microorganisms in an upstream reactor system. The even distribution of air and water is the key factor for effective nitrification and denitrification. These processes can be carried out either in a single reactor or in two separate filter stages. For denitrification, a separate anoxic filter (without process aeration) is used, with a carbon source supplied either from the wastewater stream or by dosing from an external source.

A downstream BAF can be used for final cleaning to break down any remaining organic compounds.

Piloting of biofiltration

In order to obtain reliable results on the design and effect of a large-scale implementation, we offer the rental of our pilot plant for biofiltration. This pilot plant is equipped as follows:

- Two filter columns, each with an internal diameter of 307 mm and a total height of 4000 mm

- Height of the filter material bed: 3000 mm

- Filter direction: from bottom to top

- Inlet volume: 280 - 850 L/h

- Air volume for process ventilation: 1 - 10 L/min

This plant makes it possible to test the performance and efficiency of biofiltration under real conditions and thus to plan an optimal large-scale implementation.

Photo: Our biofiltration pilot plant with control system. You are welcome to hire our pilot plant for trials. Alternatively, we can also carry out the pilot tests with your wastewater.

Conclusion

Biofiltration offers an effective and cost-saving solution for improving water quality in various applications. It significantly reduces energy requirements and operating costs, especially for membrane systems, and offers flexible, space-saving solutions for water treatment.

For further information on our products, please feel free to contact us at any time!

Photo: Structure of our ALMA BHU BAF biofiltration system in concrete construction