Pellet sludge is a special form of sludge that is produced in anaerobic reactors for industrial wastewater treatment. This sludge is characterized by its compact, granular structure and high biological activity. In UASB reactors (Upflow Anaerobic Sludge Blanket) and other anaerobic systems in particular, pellet sludge is specifically produced and used to break down organic substances and convert them into biogas (methane and carbon dioxide).

Table of contents

Formation of pellet sludge in anaerobic reactors

The formation of pellet sludge is a complex biological and physical process in which microorganisms and settleable particles form dense, spherical structures. The granules consist of microbial consortia that cooperate in different layers.

1. structure of the pellet sludge

Cellular composition:

- Pellet sludge contains various types of microorganisms, including:

- Hydrolyzing bacteria: Break down complex organic substances into smaller molecules.

- Acid producers: Produce volatile fatty acids (e.g. acetate).

- Methanogenic archaea: Convert acids and hydrogen into methane.

- These microorganisms settle in specific layers:

- Outer layer: hydrolysis and acid formation.

- Inner layer: methanogenesis.

- Pellet sludge contains various types of microorganisms, including:

Physical properties:

- Granules are spherical and typically have a diameter of 0.5-3 mm.

- High density and strength allow for good deposibility.

2. growth conditions for pellet sludge

The formation of pellet sludge requires certain process conditions:

- Hydraulic load:

- The upflow velocity in the reactor must be set so that the granules remain suspended but are not washed out.

- Nutrient supply:

- Balanced ratios of carbon, nitrogen and phosphorus promote the growth of microorganisms.

- Temperature:

- Optimum temperatures are in the range of 35-40 °C (mesophilic) or 50-55 °C (thermophilic).

- pH value:

- The pH value should be kept stable in the range of 6.8-7.2 in order to support methanogenic archaea.

Advantages of pellet sludge in anaerobic reactors

High biomass density:

- Granular sludge provides a large surface area for microbial metabolism.

- This enables a high degradation rate with a low reactor volume.

Efficient methane production:

- The granular structure promotes the coexistence of microorganisms that work together efficiently to produce biogas (methane).

Good deductibility:

- Due to the high density, the granules settle quickly, which facilitates the separation of purified water and biomass.

Robust process control:

- Granular sludge is stable against hydraulic and organic load fluctuations.

Areas of application for pellet sludge

Pellet sludge is mainly used in anaerobic reactors for the treatment of organically highly contaminated wastewater:

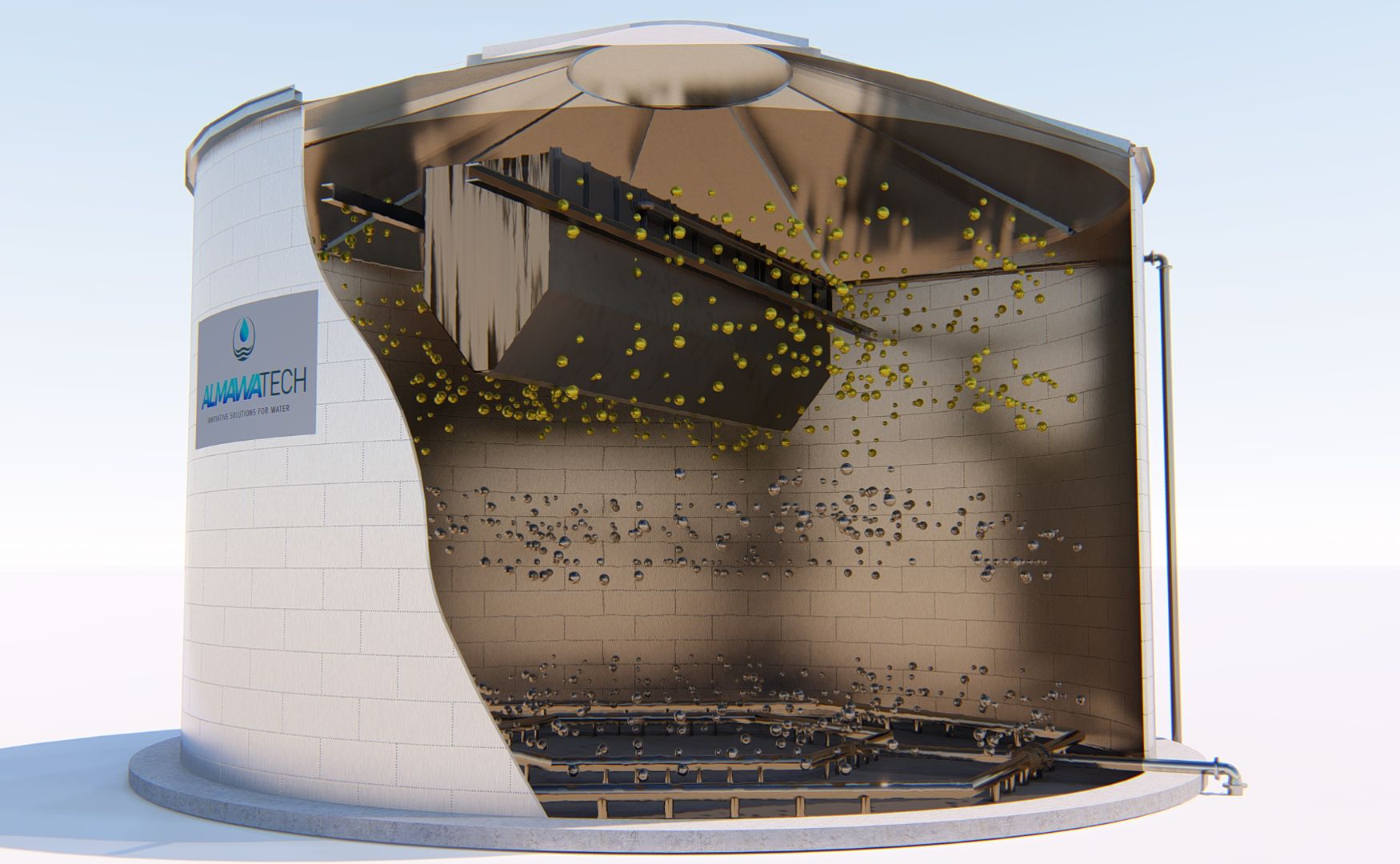

1. upflow anaerobic sludge blanket (UASB) reactors

Operating principle:

In a UASB reactor, the wastewater is passed from the bottom to the top through a layer of pellet sludge. The granules form a sludge blanket that acts as a biological filter. Within the granules, various microorganisms work together in symbiotic communities to break down the organic compounds. The resulting biogas lifts the particles slightly, whereupon they settle again by gravity.

Key functions:

- Biological activity: The granules offer a high biomass density and provide large contact surfaces for the wastewater components.

- Separation of the purified wastewater: A three-phase separator separates biogas, sludge and the purified water.

Applications:

UASB reactors are ideal for the treatment of highly organically contaminated wastewater. Typical areas of application are

- Food and beverage industry: Processing of wastewater from the production of fruit juices, dairy products and edible oils.

- Sugar and alcohol production: Efficient treatment of wastewater from fermentation processes, such as molasses-based plants.

Advantages:

- Low operating costs due to high biogas production.

- Easy maintenance and robust against load fluctuations.

Challenges:

- Initial pellet sludge formation requires time and optimum conditions.

- The sludge blanket can silt up if there is a high solids load.

Photo: Schematic representation of our ALMA BIO UASB reactor

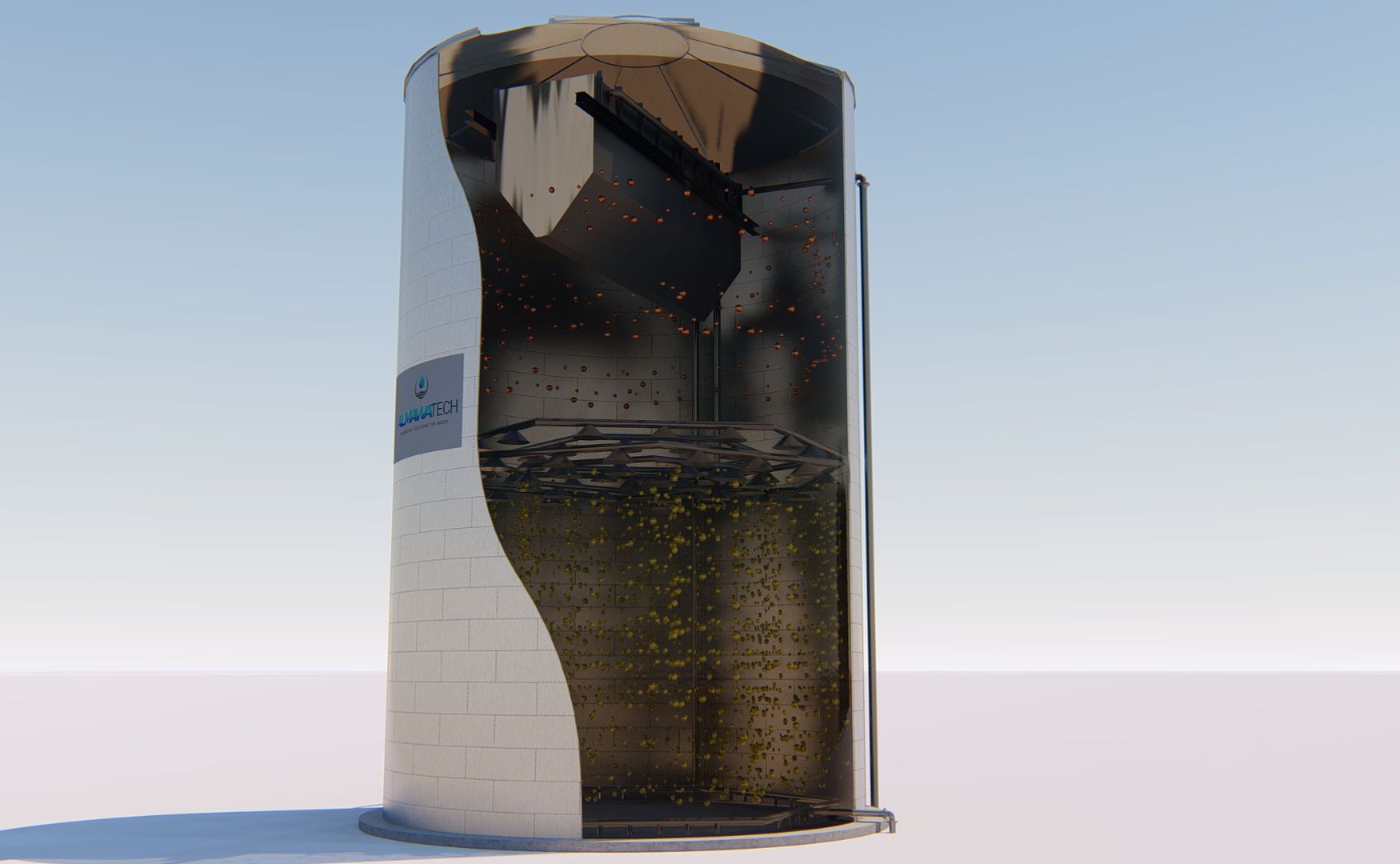

2. expanded granular sludge bed (EGSB) reactors

Operating principle:

An EGSB reactor is a further development of the UASB reactor. Here, a higher upflow velocity is generated to ensure better mixing and contact time between the microorganisms and the organic compounds. The reactor is often slimmer and higher, making efficient use of the volume. Due to the upflow velocity, the granules remain in a suspended phase, which improves the reaction kinetics.

Key functions:

- Enhanced pellet mobility: The high upflow velocity prevents the pellet sludge from settling and ensures a better contact surface.

- Increased load capacity: The more intensive mixing enables higher organic feed concentrations.

Applications:

EGSB reactors are used for wastewater with a difficult composition or high organic load:

- Chemical industry: Degradation of complex organic compounds from the production of plastics, surfactants and solvents.

- Pharmaceutical industry: Treatment of process wastewater, which often contains highly concentrated and poorly degradable organic compounds.

Advantages:

- High reaction speed and efficiency thanks to more intensive mixing.

- Compact design and low space requirement.

Challenges:

- Requires precise control of the hydraulics to keep the granules in a floating state.

- Higher investment costs compared to UASB reactors.

Photo: Schematic representation of our ALMA BHU BIO EGSB reactor

3. gas mixing reactors:

- In our ALMA BHU GMR (gas mixing reactor), the wastewater is treated efficiently under anaerobic conditions, whereby the reactor was specially developed for wastewater with high calcium concentrations. The advanced gas mixing technology of the ALMA BHU GMR ensures optimum mixing of the reaction gases in the wastewater, which greatly improves the biodegradation and precipitation of calcium.The reactor offers a particularly efficient solution for wastewater that is difficult to treat due to its high calcium content. It not only reduces the organic load of the wastewater, but also enables targeted calcium precipitation, which prevents deposits in downstream systems. This ensures stable operation and significantly reduces maintenance costs. The ALMA BHU GMR is therefore ideal for industrial applications where high calcium concentrations in wastewater are a key challenge.

Photo: Photos of our anaerobic gas mixing reactor ALMA BHU GMR

Challenges in the use of pellet sludge

Starting phase and granule formation:

- The initial formation of granular sludge can take several weeks to months.

- Solution: Inoculation with active pellet sludge from existing reactors.

Floating or disintegrating granules:

- High levels of grease or particles can destabilize the granules.

- Solution: Pre-treatment by grease separator or sedimentation.

Toxic entries:

- Heavy metals or toxic organic compounds can damage the microbial consortia.

- Solution: Monitoring the feed quality and pH stabilization.

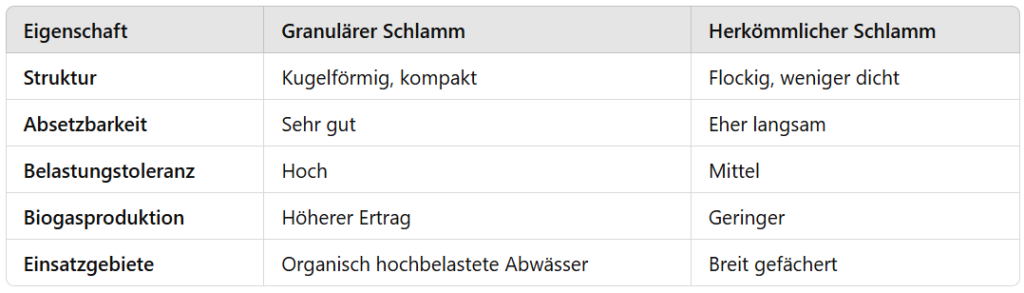

Comparison of pellet sludge and conventional sludge

Conclusion

Pelletized sludge is a key element in modern anaerobic reactors. Its compact structure, high biomass density and efficiency in methane production make it an optimal solution for the treatment of wastewater with a high organic load. Despite challenges such as granule formation or toxic inputs, pelletized sludge offers significant advantages in terms of process stability, degradation performance and sustainability. With advanced process control and targeted anaerobic system design, pelletized sludge can be effectively utilized to achieve both environmental and economic goals in wastewater treatment.

For further information on our products, please feel free to contact us at any time!