Dispersants are chemical additives that play a central role in industrial water treatment and wastewater treatment. Their main function is to bring solid particles or deposits in the water into a stable suspension and to prevent the formation of deposits on surfaces. Especially in cooling water circuits, boiler systems and membrane systems dispersants are essential to protect the system from scaling, fouling and deposits.

Table of contents

Technical background and functionality

In water-bearing systems, especially those with a high mineral content, there is a risk of insoluble substances such as calcium carbonate, silicates or corrosion products settling and forming deposits on heat exchangers, pipes and membranes. This not only leads to a loss of heat transfer capability, but also to a reduction in the flow rate and ultimately to increased energy requirements and operating costs. Dispersants prevent these deposits by keeping the particles in suspension and preventing them from coalescing.

The dispersants work in three main ways:

- Particle stabilization: Dispersants bind to the surface of the suspended particles and give them a negative surface charge. As a result, the particles repel each other and remain suspended.

- Particle size reduction: Splitting larger solid particles into smaller particles reduces the likelihood of deposits.

- Prevention of floc formation: Dispersants prevent the formation of larger flakes that could otherwise settle as deposits in pipes or heat exchangers.

Photo: ALMA AQUA operating fluid for membrane systems, cooling water and boiler water

Areas of application

Cooling water treatment: In cooling water circuits, the formation of deposits and biofouling is greatly reduced through the use of dispersants. Dispersants keep the dissolved solids in suspension, prevent limescale deposits and reduce the risk of biofilm accumulation.

Boiler systems: In boiler systems, dispersants prevent the formation of scale (calcium and magnesium deposits) on the heat exchangers, which increases the efficiency of the system and extends the service life of the system.

Membrane systems: Dispersants are important in reverse osmosis and other membrane filtration processes to protect the membrane surface from clogging by solids or organic deposits. Dispersants reduce the risk of scaling and thus prevent the loss of membrane performance.

Products from ALMAWATECH

We offer a comprehensive range of ALMA AQUA dispersants that have been specially developed to meet the requirements of industrial water treatment systems:

ALMA AQUA cooling water: Our dispersants for cooling water applications prevent the build-up of solids and biofilms in circuits, increase system efficiency and extend maintenance intervals.

ALMA AQUA boilers: For boiler systems, we offer dispersants that effectively prevent deposits in pipes and heat exchangers and thus improve fuel efficiency.

ALMA AQUA membrane: In membrane filtration systems, especially in reverse osmosis systems, our product range ensures that the membrane surfaces remain clean and scaling is avoided. These dispersants are specially designed to extend the service life of the membranes and reduce operating costs.

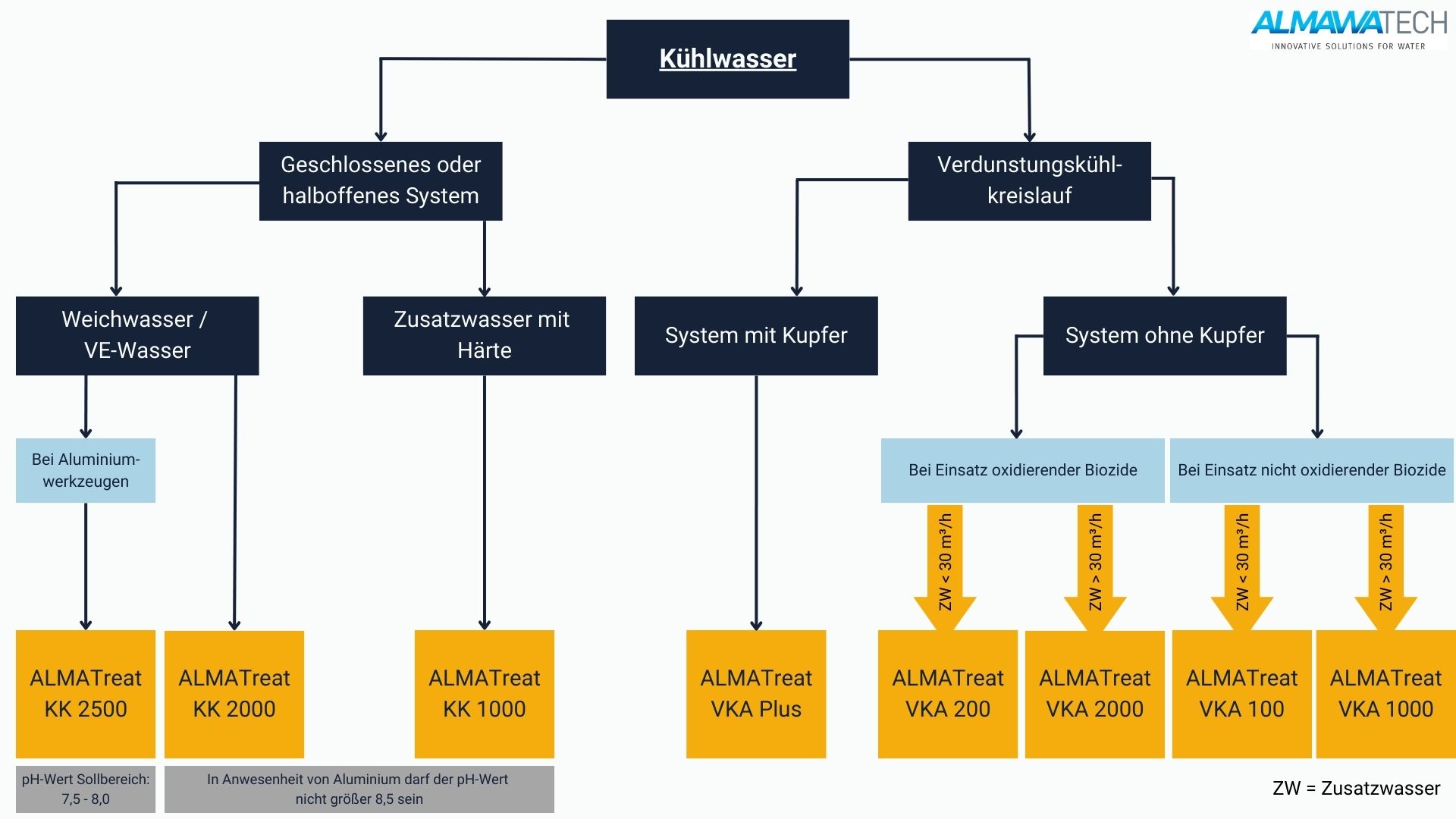

Photo: Product overview cooling water treatment (ALMA AQUA cooling water)

Advantages of using dispersants

- Increased efficiency: By reducing deposits in water-bearing systems, energy consumption is lowered and heat transfer efficiency is improved.

- Cost savings: The use of dispersers reduces the need for frequent cleaning and maintenance work, resulting in lower operating costs.

- Longer service life of systems: By preventing deposits, pipes, heat exchangers and membranes are protected, which significantly increases the service life of the systems.

- Reduction of biofouling: In combination with biocides, dispersants help to prevent biofilm build-up, which is particularly important in cooling systems.

Conclusion

Dispersers are an indispensable part of modern industrial water treatment processes. They help to increase efficiency, reduce operating costs and at the same time extend the service life of the plant technology. ALMAWATECH offers with the ALMA AQUAproduct range, ALMAWATECH offers high-performance dispersants that are specially tailored to the different requirements of cooling water systems, boiler systems and membrane filtration processes.

For further information on our products, please feel free to contact us at any time!