A steam boiler system is an industrial system for generating steam, which is used in various processes such as energy generation, in heating systems or for direct use in industrial production processes. The steam boiler acts as a vessel in which water is vaporized by applying heat. This process requires strict control of the water quality, as impurities in the boiler can lead to deposits (scaling), corrosion and operational failures.

Table of contents

Technical functionality

The operating principle of a steam boiler system is based on heating water using fuels (such as gas, oil, coal or biomass) or electrical energy until it evaporates. The steam produced is then used for various industrial applications. To maximize the service life of the system and ensure safe and efficient operation, comprehensive water treatment is required. Softening, desalination and conditioning of the boiler feed water play a central role in this.

Photo: State-of-the-art steam boiler system

Challenges in water quality

The quality of the boiler feed water is of crucial importance for the safe operation of the steam boiler system. Impurities such as hardness constituents, oxygen, carbon dioxide and dissolved solids can cause serious operating problems:

- Scaling (scale formation): Deposits of calcium and magnesium salts lead to inefficient heat transfer and overheating of the boiler.

- Corrosion: Oxygen and carbon dioxide in the feed water attack the metallic components of the system, which can lead to leaks and corrosion damage.

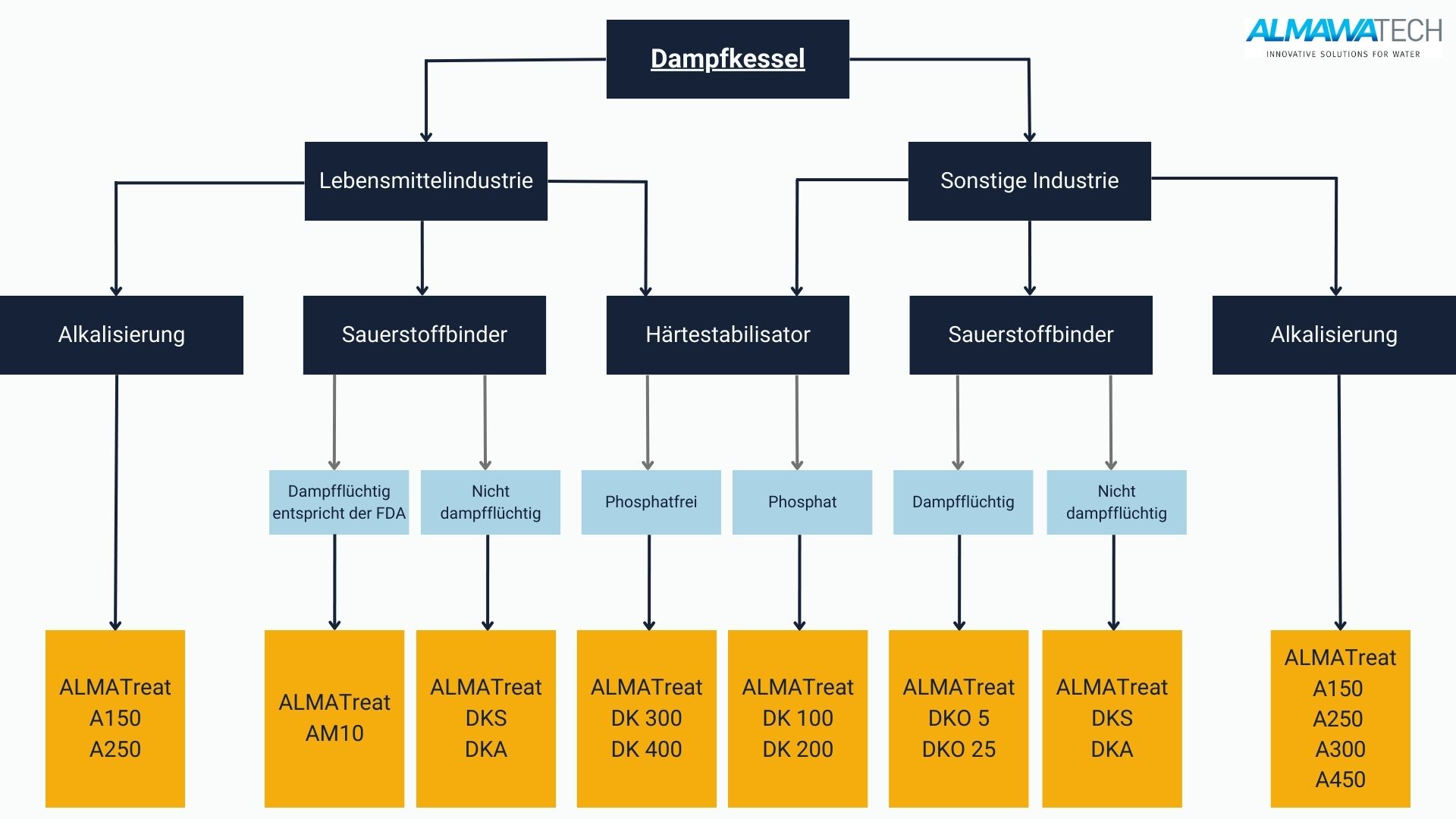

ALMAWATECH products to support steam boiler systems

To avoid these problems, ALMAWATECH offers a wide range of equipment and treatment systems that have been specially developed for steam boiler systems:

1st ALMA AQUA boiler

Boiler water systems require special chemicals to prevent corrosion, deposits and steam contamination. The ALMA AQUA Boiler-products offer comprehensive solutions for boiler water treatment:

Corrosion inhibitors: They prevent the oxidation of metal surfaces in the boiler systems and extend the service life of the system components.

Hardness stabilizers: These chemicals prevent the formation of scale and limescale deposits on the heat exchanger surfaces, which improves heat transfer efficiency and reduces energy consumption.

Defoamers: Defoamers prevent the formation of foam in the boiler water, which can lead to steam contamination and impair boiler operation.

Dispersants: They keep suspended solids in suspension in the water and prevent particles from settling on heat exchangers and pipes.

Oxygen binders: These remove dissolved oxygen from the water to prevent corrosion in boiler and condensate systems.

Alkalizing agents: These agents are used to increase the pH value in the boiler water and improve the conditions for corrosion prevention.

Biocides: Biocides that effectively combat microorganisms are used to prevent microbial corrosion (MIC) and fouling in the pipes and heat exchangers of boiler systems.

Photo: Product overview of various operating materials for steam boiler systems (ALMA AQUA boilers)

2 ALMA ION - Softening systems

Reliable water softening is crucial to prevent the formation of scale caused by calcium and magnesium ions. Our ALMA ION softening systems work on the basis of ion exchange resins, which remove hardness formers from the feed water. This results in soft water with a hardness level of almost 0 °dH, which is ideal for use in steam boiler systems.

The ALMA ION softening systems offer:

- Automatic regeneration: To ensure uninterrupted operation.

- High-performance resins: For a long service life and high capacity.

- Fully automatic control: monitoring and control systems for precise control of water hardness.

Photo: ALMA ION water softener for industrial applications

Conclusion

Steam boiler systems place high demands on water treatment in order to avoid operational failures, efficiency losses and corrosion damage. Through the use of our ALMA AQUA boiler-chemicals and ALMA ION softening systems, optimum water quality can be achieved and trouble-free operation of the steam boiler system can be ensured. This not only extends the service life of the system, but also reduces operating costs and improves energy efficiency.