Biological deposits, also known as biofilms or biofouling, are accumulations of microorganisms such as bacteria, algae, fungi and other biological materials on surfaces in contact with water. These deposits occur in many industrial water circuits, such as cooling water systems, membrane systems (reverse osmosis) and pipelines, and pose a challenge to the efficient operation and long-term reliability of water treatment systems.

Table of contents

Formation of biological deposits

The formation of biofilms begins with the attachment of microorganisms to surfaces that are in continuous contact with water. This process is characterized by the following steps:

Primary attachment: Individual microorganisms, such as bacteria, attach themselves to the surface. This is influenced by physical interactions such as van der Waals forces, electrochemical attraction and the chemical structure of the surface. Smooth, hydrophobic surfaces are less prone to biofilm formation than rough, hydrophilic materials.

Cell division and EPS production: After the microorganisms have attached themselves to the surface, they begin to multiply and produce an extracellular polymeric substance (EPS) that stabilizes the biofilm. This sticky substance forms a protective matrix consisting of polysaccharides, proteins and other organic materials. It holds the microorganisms together and provides protection against external influences such as chemicals or mechanical cleaning.

Biofilm formation and growth: Over time, the biofilm continues to grow as more and more microorganisms colonize and strengthen the EPS network. In industrial systems, this process can lead to a significant increase in flow resistance and a reduction in heat transfer, particularly in heat exchangers and cooling circuits. In membrane systems such as reverse osmosis, biofouling can block the membrane pores and reduce the transmembrane flow (TMP), which impairs the efficiency and service life of the system.

Photo: Biological growth on a heat transfer surface of a cooling circuit

Technical background and effects

Biological deposits can have a serious impact on the operation of industrial water and wastewater systems:

Reduced system efficiency: In cooling circuits, biofilms lead to a reduction in heat transfer efficiency. The biofilm acts as a thermal insulator, which means that more energy has to be used to cool or heat processes. In pipelines, biofouling increases the hydraulic resistance and therefore the energy required to pump the water.

Increased risk of corrosion: Biological deposits can accelerate the corrosion rate of metallic surfaces through microbial induced corrosion (MIC). This is caused by microorganisms that promote sulphate- or sulphur-reducing processes under low-oxygen conditions, which leads to the formation of corrosive substances such as hydrogen sulphide (H₂S).

Deterioration of water quality: Biofilms can serve as a reservoir for pathogenic microorganisms that are distributed through the water system. This poses a serious problem, particularly in the food industry and in drinking water treatment.

Membrane fouling: In membrane systems, such as reverse osmosis, the formation of biofilms leads to a drastic reduction in the flow rate and an increased need for chemical cleaning cycles. This reduces the service life of the membranes and increases operating costs.

Prevention and control measures

Various strategic measures are taken in practice to minimize the negative effects of biofouling:

1. chemical treatment

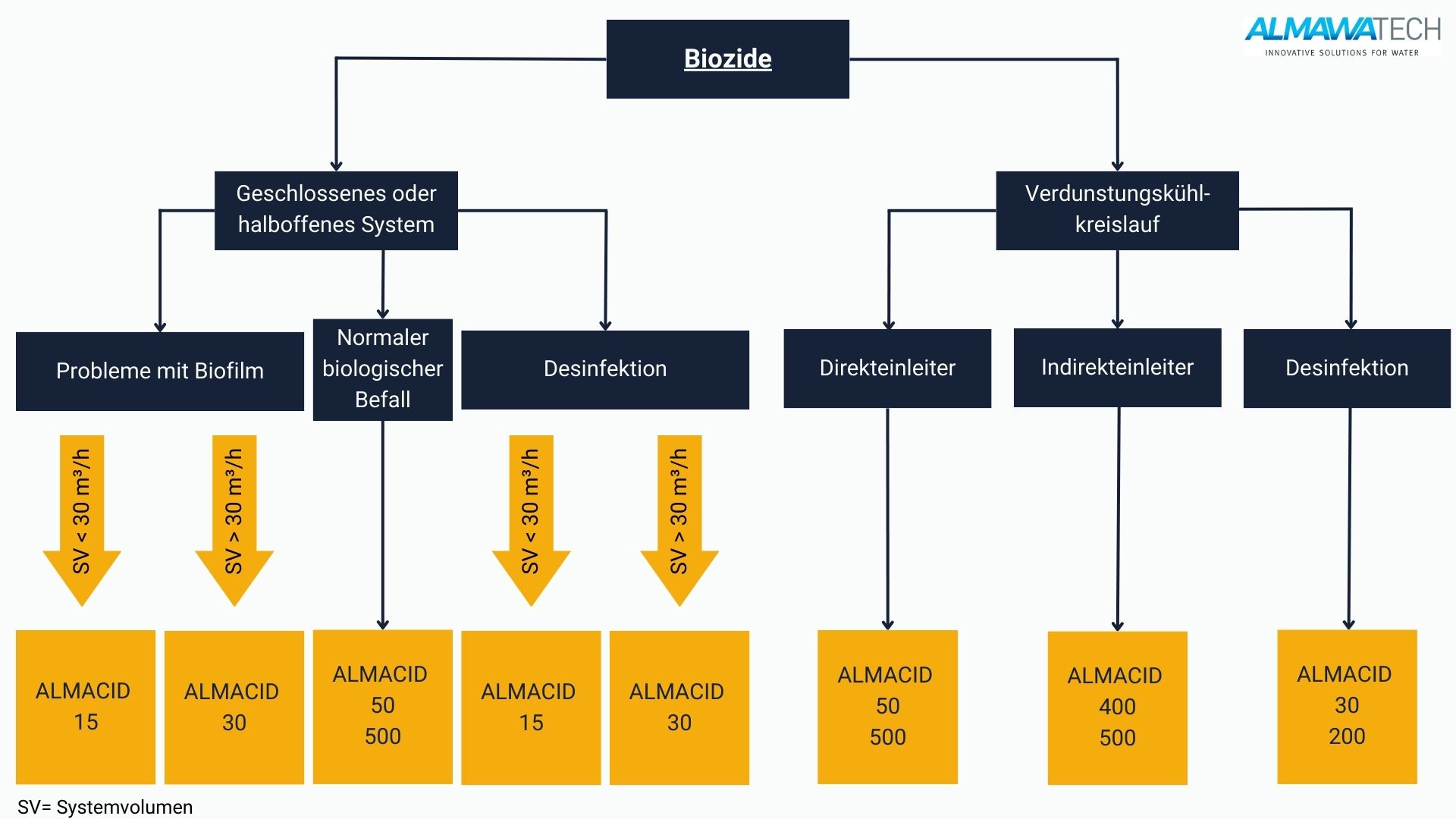

- Biocides: Biocides that kill microorganisms or inhibit their growth are used to prevent the formation of biological deposits. Examples of common biocides are chlorine, sodium hypochlorite or peracetic acid. However, chlorine-free biocides must be used in systems in which membranes are used, as chlorine can damage the membranes.

- Dispersants: These chemicals help to dissolve already formed biofilms and destabilize the EPS matrix so that the biofilm can be more easily removed mechanically.

Photo: Product overview of our biocides for cooling circuits. For more information about our operating fluids for cooling water systems, visit our website at: ALMA AQUA Cooling Water

2. physical procedures

- Rinsing and mechanical cleaning: Regular flushing with high-pressure water or air/water mixtures can help to reduce the build-up of microorganisms. The use of mechanical cleaning systems, such as brushes or ball cleaning systems, can be effective in heat exchangers and pipes.

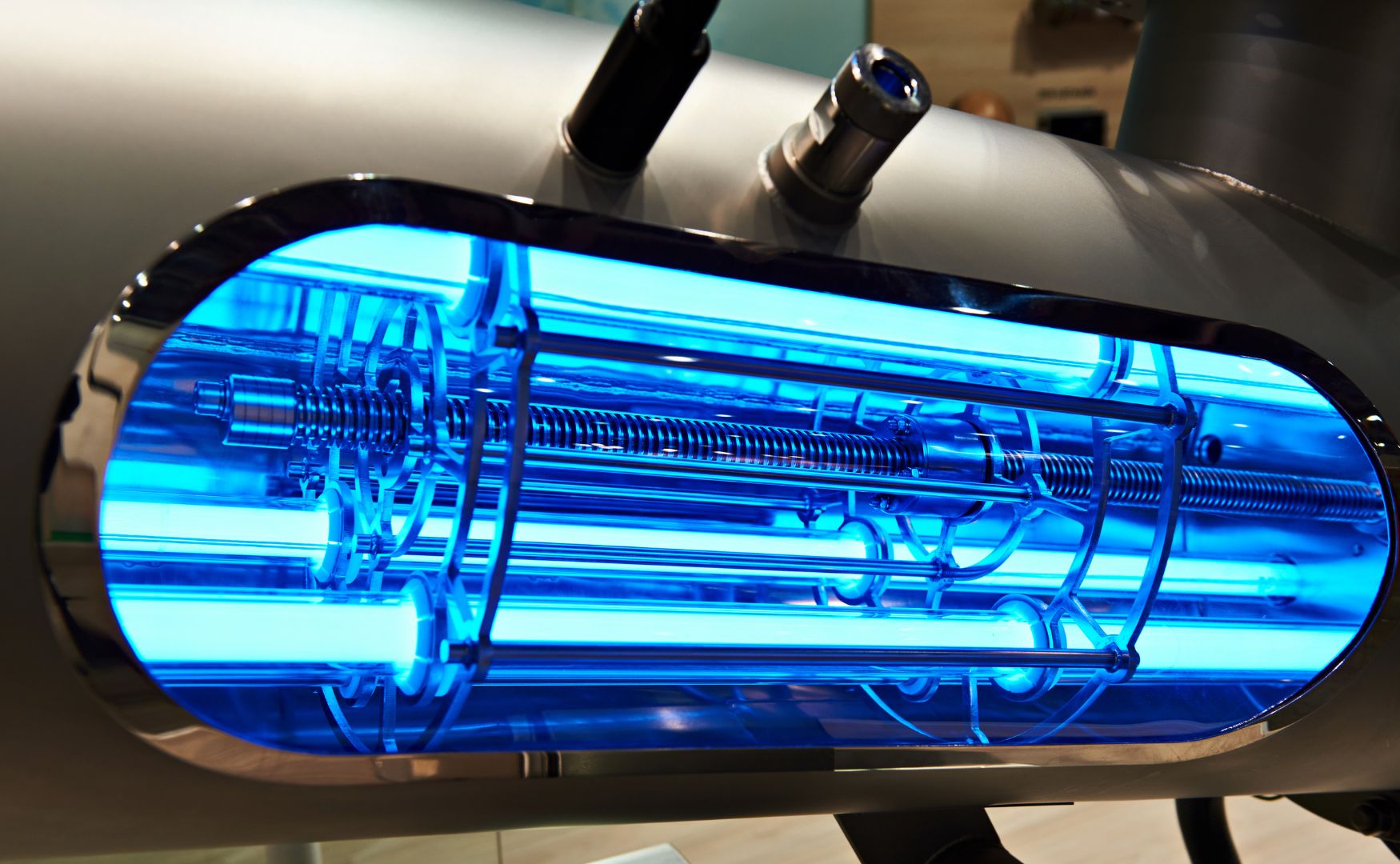

- Ultrasound or UV light: In some applications, ultrasound or UV irradiation is used to destroy microorganisms directly or to prevent them from adhering to surfaces. UV light is a common method in drinking water systems for disinfection and to prevent biofouling.

Photo: UV reactor for the disinfection and hygienization of wastewater and process water(ALMA OXI UV)

3. system design and optimization

- Material selection: The use of corrosion-resistant and smooth materials can reduce biofilm formation, as microorganisms find it more difficult to adhere to such surfaces.

- Optimization of the flow conditions: Biofilms prefer to form in areas with low flow. The formation of deposits can be reduced by optimizing the flow velocity or avoiding dead zones in pipes.

4. biological pre-treatment

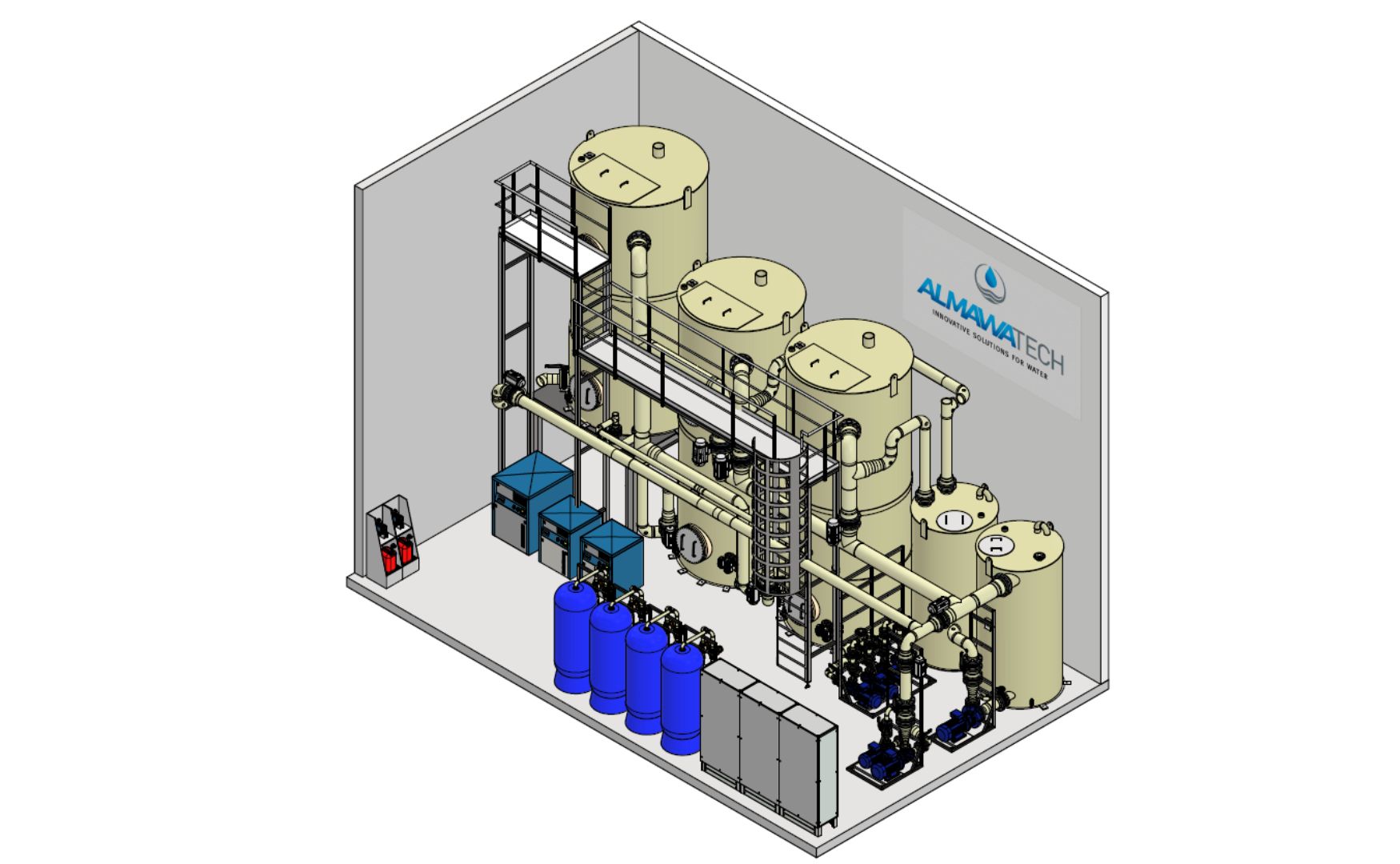

Biofiltration: A particularly efficient method for reducing biofouling in downstream water treatment systems is the use of biological filtration systems. ALMAWATECH offers the solution for this ALMA BioFil Compact solution. This system is particularly suitable for wastewater flows of up to 50 m³/h and can be used upstream of membrane systems such as reverse osmosis to remove small residual loads of organic substances. This significantly reduces the potential for biofouling and ensures more efficient and economical operation of reverse osmosis.

ALMA BioFil Compact is particularly useful in the treatment of wastewater, such as vapor condensates from the food industry (especially dairies). By reducing organic matter before it enters membrane systems, the service life of the membranes is extended and the cleaning effort is significantly reduced. This is a sustainable approach to preventing biofouling in the long term and minimizing operating costs.

Photo: 3D design of our ALMA BioFil Compact biofiltration system for removing organic pollutants

Relevance in practice

In industrial practice, biological deposits are a frequent cause of operational malfunctions and efficiency losses. In cooling water systems, biofilms can reduce the efficiency of heat transfer by up to 20 %, while in reverse osmosis systems, operating costs can increase dramatically due to increased cleaning cycles and premature membrane wear. Therefore, continuous monitoring and treatment of biofouling is an essential part of water treatment plant management.

Conclusion

Biological deposits pose a complex challenge in industrial water treatment. The formation of biofilms can lead to considerable losses in efficiency, increased maintenance costs and a deterioration in water quality. By using targeted measures such as chemical treatment with biocides, physical cleaning techniques (such as the ALMA OXI UV treatment), biofiltration systems and a well thought-out system design, the negative effects of biofouling can be controlled and minimized. A deep understanding of the biological processes and their impact on the system technology is essential to ensure efficient and cost-effective water treatment.