Task

The GEOMAR Helmholtz Center for Ocean Research Kiel is one of the world's leading institutions in the field of marine research. It investigates the complex interactions in the ocean - from the deep sea to the atmosphere - with an interdisciplinary focus on physical, chemical, biological and geological processes.

GEOMAR's research focuses are divided into the following areas:

Ocean circulation and climate dynamics

Marine Biogeochemistry

Marine ecology

Dynamics of the ocean floor

In 2023, ALMAWATECH was commissioned with the planning and construction of a seawater intake and evacuation station, including a multi-stage filtration section, pigging station, pump and control technology.

We are proud to be able to make a contribution to GEOMAR's pioneering marine research with our system technology.

Photo: Suction station with Venturi nozzle and sinus pumps for feeding the drum filters

Design data

Preparation quantity:

- 2 x 25m3/h

- Redundant design of the system and control technology

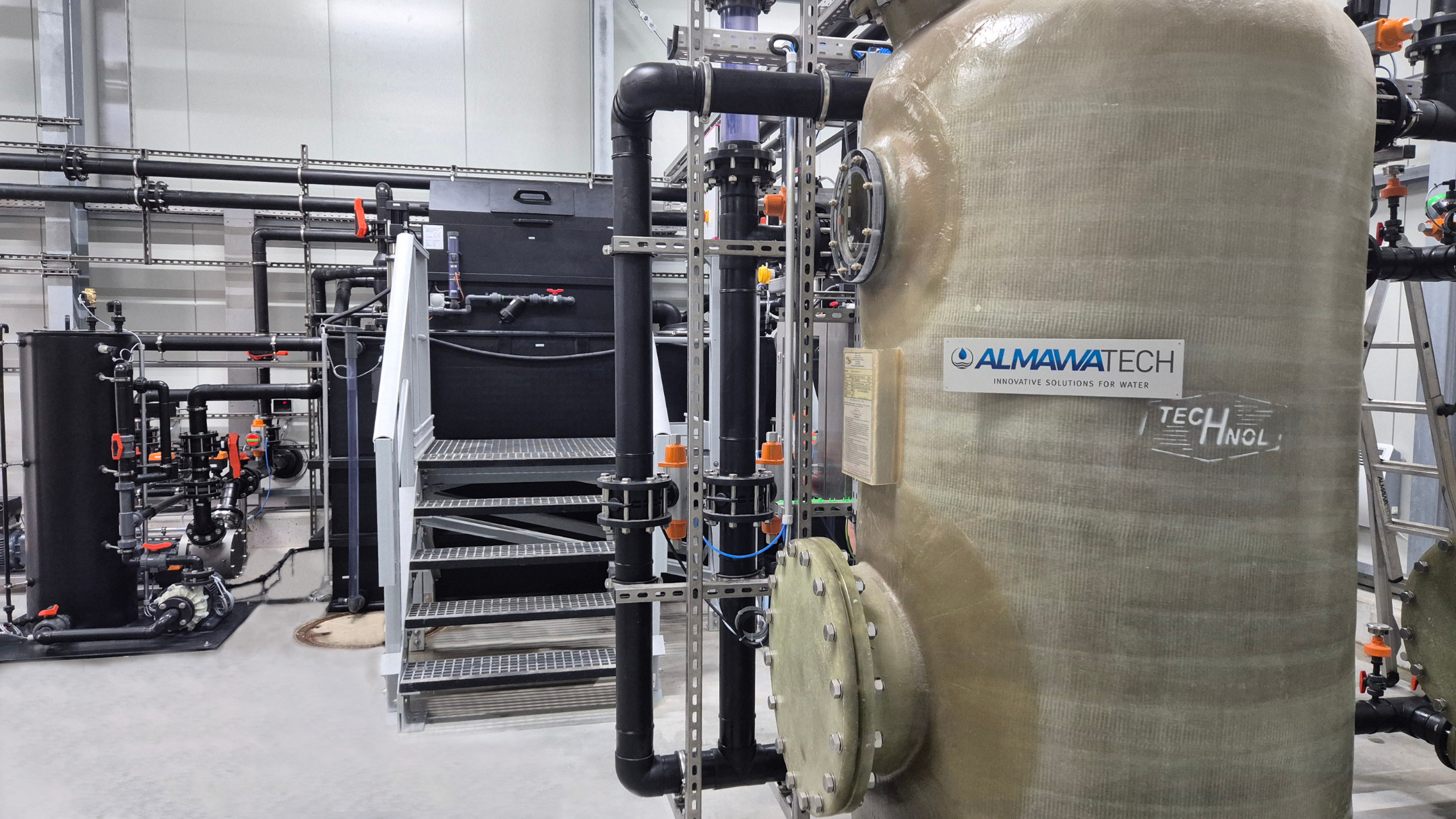

Photo: ALMA FIL glass filter designed as a redundant pendulum system with manhole and activated filter glass with hydrophobic surface

Solution & implementation

Raw water drawn in from the Kiel harbor basin was to be treated in such a way that it met the high purity requirements of marine biological and chemical experiments. At the same time, operational safety, corrosion protection and long-term operation with as little maintenance as possible were required.

1st suction station:

The raw water is sucked in from the harbor using an evacuation station with Venturi nozzle designed by ALMAWATECH. The suction lines are made of slotted PE pipe and are designed so that they can be lifted out of the water by crane and cleaned manually if necessary. This design ensures that long-term operation is guaranteed even in the event of fouling or deposits.

2. multi-stage filtration system ALMA FIL

In the first filtration step, the seawater enters a drum filter made entirely of corrosion-free PE. The microfiltration in the drum filter removes coarse and suspended solids and thus represents the first purification stage. The pre-treated water is then transferred to a stacking tank, which serves as a hydraulic buffer and enables the subsequent filtration stages to be fed evenly.

The main treatment takes place via sand filtration with the filter system ALMA FIL. The filters have a redundant pendulum design, are made of GRP and are equipped with a nozzle base and manhole. Backwashing can be controlled either by time or differential pressure. The redundancy ensures uninterrupted operation at all times, even during backwashing.

3. pigging station, insulation & trace heating

After filtration, the treated seawater is transported to GEOMAR via four 1.5 km long seawater pipes. At the transfer point, there is a valve island in an underground shaft and an intake station for further internal distribution. To prevent biological growth in the pipelines (e.g. algae or mussels), the pipelines are equipped with a pigging station. The pipes themselves are also insulated and fitted with trace heating to ensure temperature stability and frost protection.

4. automation

The control and automation technology is housed in a stainless steel control cabinet (V4A) and has a redundant design. It enables fully automated operation including process monitoring and offers remote access for system monitoring and diagnostics if required.

Photo: Drum filter and ALMA FIL glass filter (side view of the system)

Customer benefits

Constant water quality for sensitive laboratory and pilot tests

Corrosion-free choice of materials (PE, GRP, stainless steel) for a long service life

Redundant key components ensure maximum operational reliability

Pigging station and trace heating minimize biofouling and downtime

For further information on our water treatment systems, please do not hesitate to contact us.

Photo: Drum filter and ALMA FIL glass filter (side view of the system)

References Seawater treatment & research

Drum filter,

Sand filter,

Pumping station,

Pigging station

Similar projects

Similar projects

GEOMAR, seawater treatment, ALMA FIL

Construction of redundant multi-stage filtration plant with pigging station and intake system for the GEOMAR Helmholtz Center for Ocean Research in Kiel.

GEOMAR Helmholtz Center for Ocean Research Kiel, Germany, ALMA FIL

Construction of a water treatment plant for seawater and artificial seawater with a salt content between 15 - 35 % for the GEOMAR Helmholtz Center for Ocean Research Kiel.

3M, Germany, ALMA OSMO Process

Construction of a multi-stage pilot membrane plant for the removal of per- and polyfluorinated chemicals (PFAS) from wastewater with a hydraulic capacity of 1 m³/h for the company 3M.

Schultheis Weiher, Offenbach, ALMA NeoDAF HDED

Dissolved air flotation (ALMA NeoDAF HDED) in container design for the efficient reduction of phosphorus concentrations from the "Schultheis-Weiher" bathing water in Offenbach.

TU Kaiserslautern, ALMA BIO, FENTON, UV, AK

Customized research plant in container design with coarse filtration, biological treatment, ultrafiltration, activated carbon filter, ozonation, hydrogen peroxide dosing and UV treatment for the TU Kaiserslautern.

German Aerospace Center, Germany, ALMA OSMO VE

Production of 750 liters of ultrapure water per day by means of softening, reverse osmosis and UV treatment from seawater for the German Aerospace Center (DLR).