ALMA BHU OXI

Wet-chemical oxidation system for the elimination of toxic and poorly degradable organic compounds. Can be realized as an ozone system or according to the Fenton process.

Ozonation or Fenton process possible depending on the COD concentration in the wastewater and the objective

Hydraulic ozonation capacity: 20 - 2,000 m³/h

Hydraulic output Fenton: 0.5 - 20 m³/h

ALMA OXI Fenton

In our ALMA OXI Fenton plant, hydrogen peroxide is used in combination with divalent iron salts within a precisely defined pH range to eliminate poorly degradable or refractory COD and trace substances.

For the elimination of persistent, toxic and trace substances that are difficult to break down

Hydraulic capacity: 20 - 1,000 m³/d

Available as a continuous system as well as in a batch process

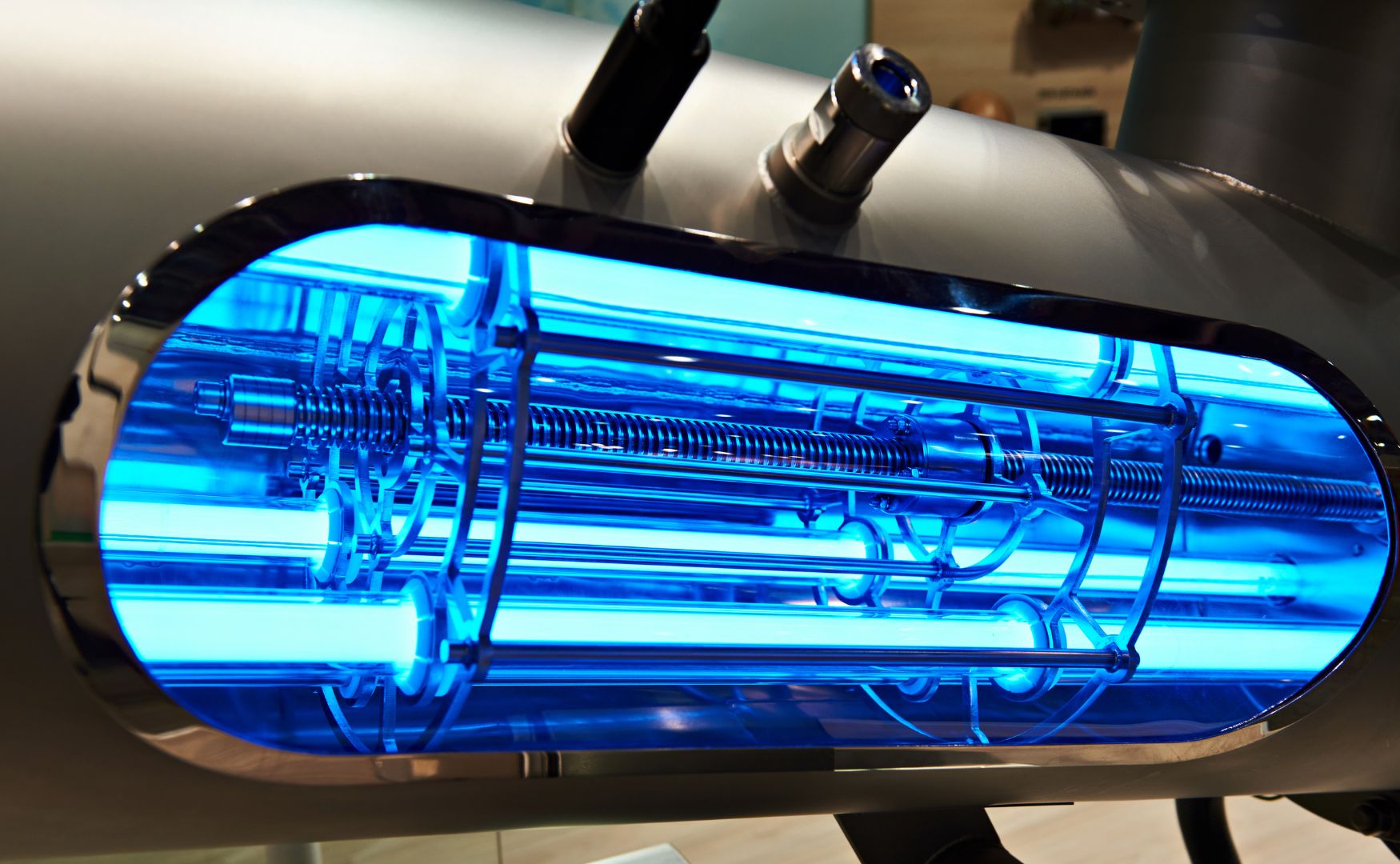

ALMA OXI UV

UV oxidation is a highly effective combination process that is particularly suitable for the hygienization of process water for reuse in the industrial water cycle. It also enables the removal of trace substances and refractory COD.

UV oxidation for the elimination of trace substances and refractory COD

Hydraulic output: 1 - 200 m³/h

UV station from renowned partners

ALMA OXI O2

With our ALMA OXI O2 oxygen generation system, you can continuously generate first-class oxygen of the highest purity from ambient air. The purity of this oxygen can be flexibly adjusted between 90 and 95 %.

Can be used both for waste water applications and in drinking water treatment

Oxygen production rate: 1.5 - 200 m³/h

Continuous monitoring of all operating parameters

Get in touch with us!