ALMA BIO UASB

Your experts for biogas plants - reliably available

References biogas plants

Bioethanol, EGSB biogas reactor, ALMA BHU EGSB

Construction of an EGSB reactor with approx. 700 m³ and a COD load of 10,000 kg/d for the recovery of biogas from the production of bioethanol.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Biogas plant for Keszthely sewage treatment plant, Hungary, ALMA BHU GMR

Construction of a biogas plant for the sludge utilization of a municipal sewage treatment plant with an energy production of 2,000 kWh/d in Hungary.

Advantages of anaerobic wastewater treatment

Advantages of our UASB reactor

Downloads

Tender text

Please contact our specialist for biogas plants: E-Mail

FAQ - ALMA BIO UASB biogas plant

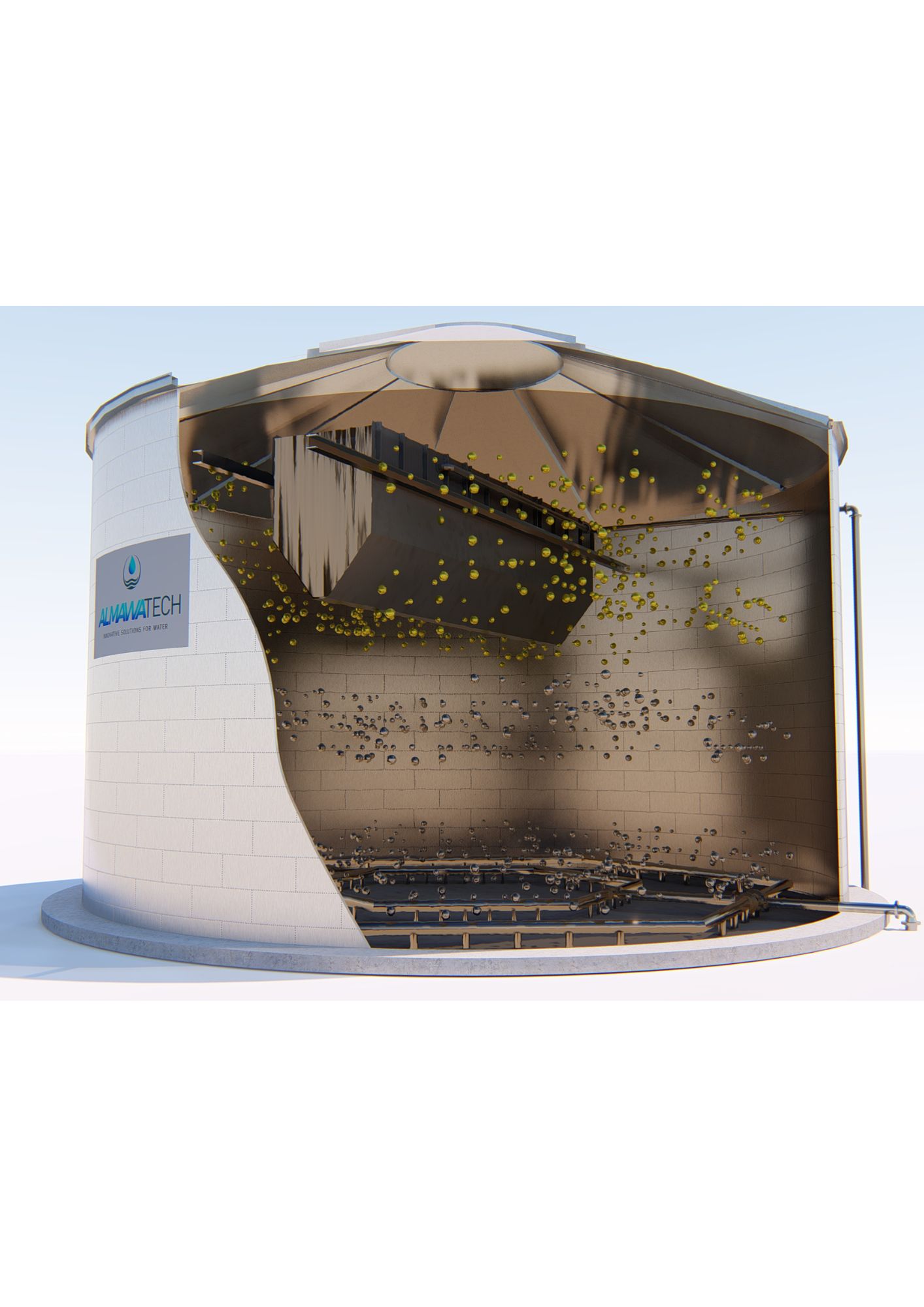

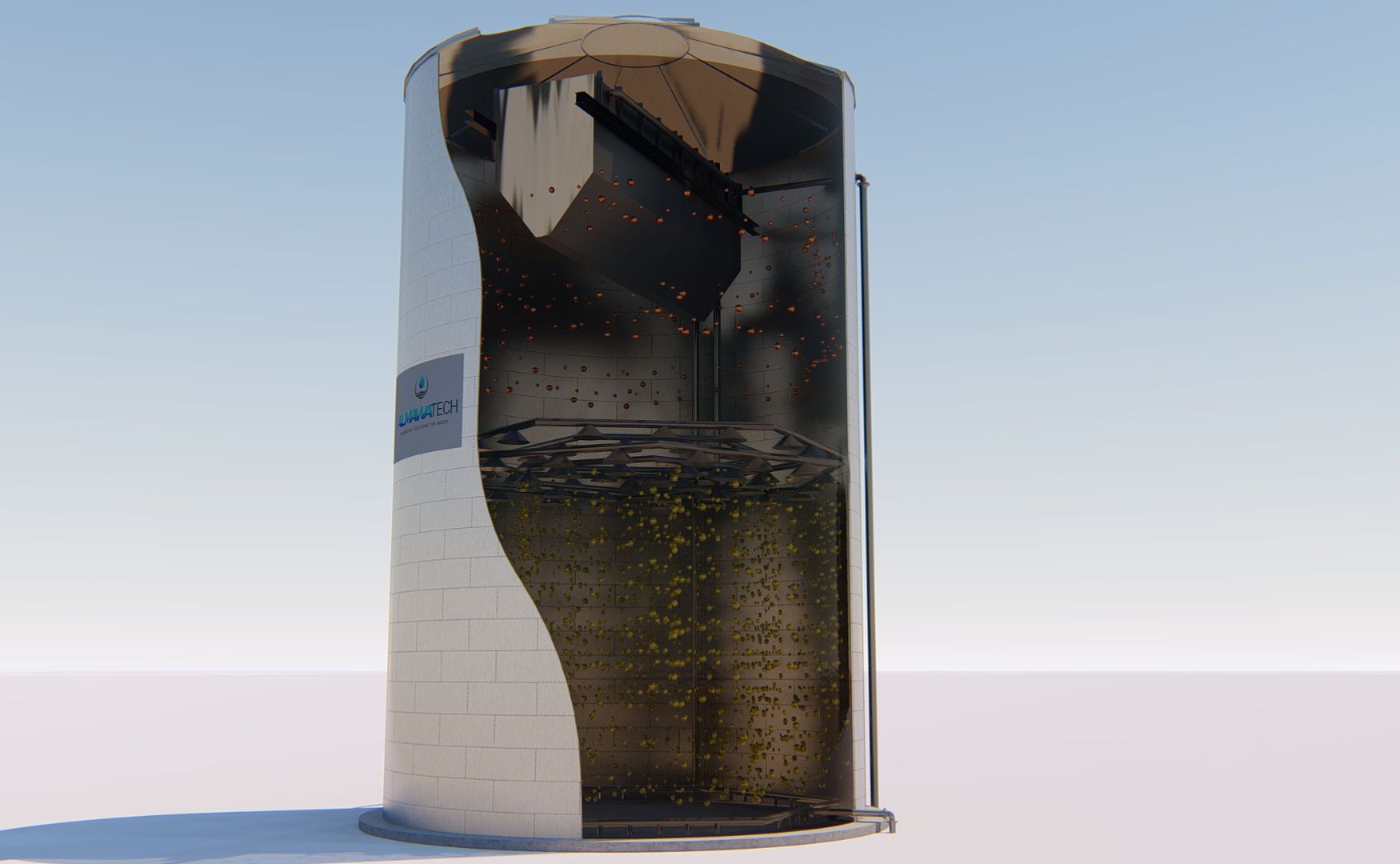

What is the ALMA BHU UASB reactor and how does it work?

The ALMA BHU UASB (Upflow Anaerobic Sludge Blanket) reactor is an anaerobic wastewater reactor for treating industrial wastewater with medium to high organic loads. It is one of the most proven anaerobic processes worldwide and is used in particular when robust, energy-efficient, and durable solutions are required.

Functional principle of the ALMA BHU UASB

In the ALMA BHU UASB, wastewater flows from bottom to top through a sludge blanket made of anaerobic biomass. The organic substances are broken down by microorganisms and converted into biogas (methane).

The rising gas bubbles ensure natural mixing without the need for mechanical agitators. In the upper part of the reactor, a 3-phase separator separates:

the biogas produced

the treated wastewater

the biomass retained in the reactor

Role of the UASB in the plant design

The ALMA BHU UASB often serves as:

central anaerobic stage

economic pretreatment before aerobic systems

CSB reduction stage with simultaneous energy recovery

Summary

The ALMA BHU UASB is an anaerobic upflow reactor that breaks down organically contaminated wastewater, produces biogas, and operates without mechanical mixing.

For which CSB concentrations and space loads is the ALMA BHU UASB reactor suitable?

The ALMA BHU UASB is designed for industrial wastewater with medium to high COD concentrations and is particularly suitable for applications with stable or moderately fluctuating loads.

Suitable CSB areas

Typical conditions of use are:

CSB concentrations from approx. 800–1,000 mg/l

easily biodegradable organic substances

continuous or evenly buffered wastewater accumulation

Maximum room load

The ALMA BHU UASB achieves organic loadings of up to

15 kg COD/m³·d.

This puts him:

below the power density of an EGSB reactor

significantly above classic large-volume bioreactors

This load allows for economical and stable wastewater treatment with moderate space requirements.

Typical industries of application

Food and beverage industry

Dairies

breweries

Sugar and starch industry

Process wastewater with uniform composition

Summary

The ALMA BHU UASB is suitable for COD concentrations above 1,000 mg/l and allows for space loads of up to 15 kg COD/m³·d.

What are the special features of the ALMA BHU UASB reactor in terms of process technology?

The ALMA BHU UASB features a simple, robust, and proven reactor geometry that is specifically designed for continuous industrial operation.

Sludge blanket with high biological activity

The anaerobic biomass forms a stable sludge layer with:

good sedimentation capacity

high biodegradability

low discharge tendency

Efficient 3-phase separator

The integrated 3-phase separator ensures:

Safe separation of gas, water, and sludge

low biomass losses

clear flow quality

Low energy and maintenance costs

Since no mechanical agitators are required:

the energy requirement is very low

maintenance requirements are significantly reduced

plant availability increases

Summary The ALMA BHU UASB utilizes a stable sludge blanket and an efficient 3-phase separator for low-energy and low-maintenance operation.

What advantages does the ALMA BHU UASB reactor offer over other anaerobic systems?

The ALMA BHU UASB is particularly advantageous when operational reliability, simplicity, and durability are paramount.

Key advantages at a glance

Proven method used worldwide

Room load up to 15 kg COD/m³·d

Very low energy consumption

No mechanical agitators in the reactor

High operational reliability

Long service life

Numerous references in the industry

Compared to high-load systems such as EGSB, the UASB is:

less complex hydraulically

more tolerant of operational deviations

particularly suitable for even inflows

Summary

The ALMA BHU UASB impresses with its simple technology, low energy consumption, and high operational reliability for medium to high COD loads.

When does it make economic sense to use an ALMA BHU UASB reactor?

The use of an ALMA BHU UASB is particularly useful when:

a robust anaerobic base level is required

Wastewater composition is relatively constant

Energy efficiency is a priority

Investment and operating costs should be minimized

Economic benefits

Reduction of COD load prior to aerobic post-treatment

Savings in ventilation energy

Biogas production for own energy supply

Low maintenance and spare parts requirements

The UASB is often the most economical anaerobic solution when extreme space constraints are not an issue.

Summary

The ALMA BHU UASB is economically viable for constant, easily degradable wastewater and moderate space loads of up to 15 kg COD/m³·d.

How can the ALMA BHU UASB reactor be integrated into existing plants?

The ALMA BHU UASB can be flexibly integrated into existing wastewater treatment concepts:

as a preliminary stage before aerobic treatment stages

in combination with neutralization, CP plants, or flotation

as part of modular ALMA complete systems

Thanks to its simple design, the reactor can:

be bolted or welded

be adapted to existing hydraulic concepts

can be easily expanded or retrofitted

Summary

The ALMA BHU UASB can be flexibly integrated into existing industrial wastewater treatment plants as an anaerobic pre-treatment stage.

Similar products: Biogas from waste water

ALMA BHU BIO EGSB

Two-stage anaerobic reactor ALMA BHU BIO EGSB, which can be fed with a high COD load due to the two-stage biogas extraction.

ALMA BHU GMR

Get in touch with us!