ALMA BHU GMR

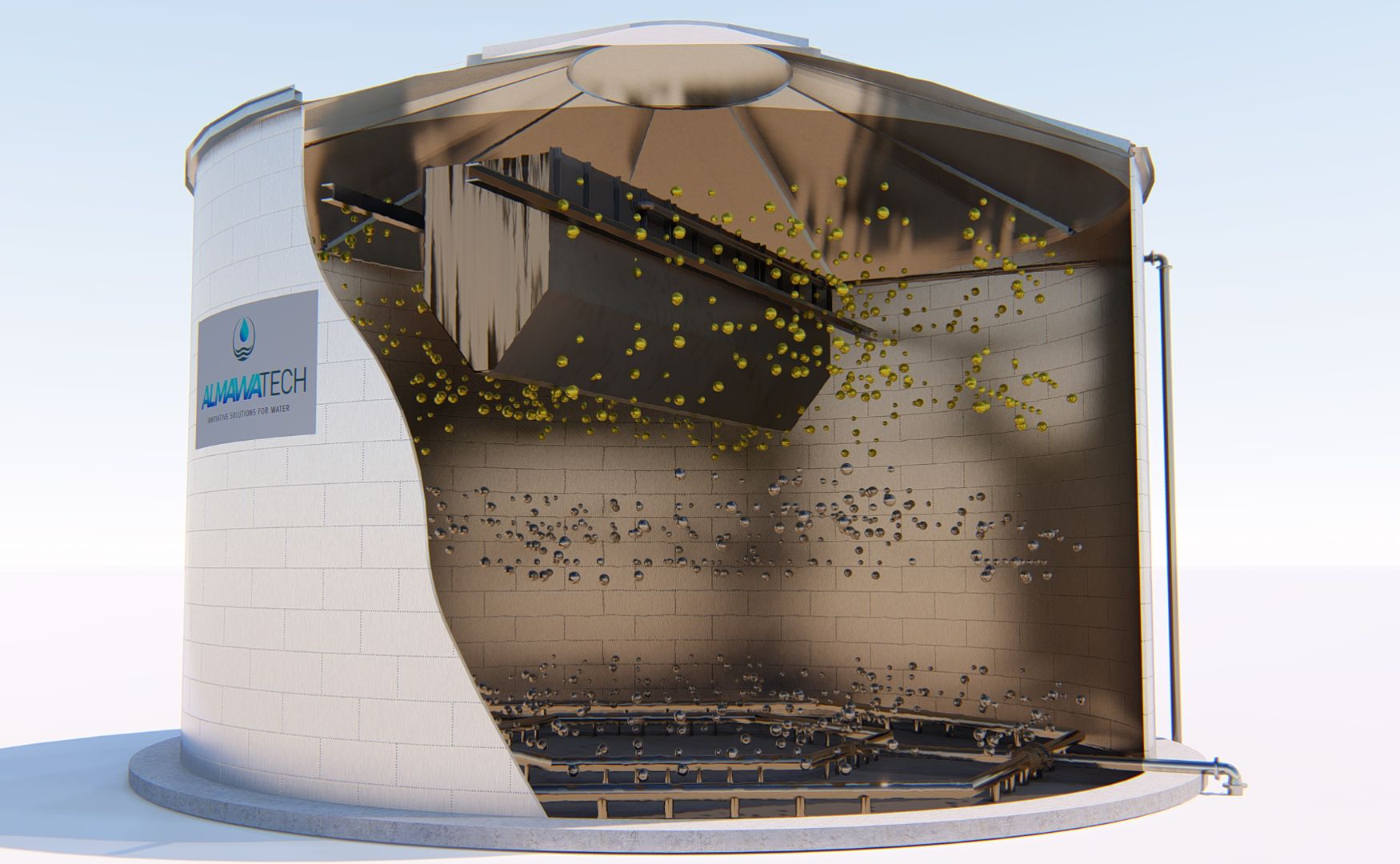

This innovative process also includes a downstream sedimentation tank that effectively returns the biomass to the anaerobic reactor. This targeted recirculation enables the biogas yield to be maximized and contributes to the overall efficiency of the ALMA BHU GMR.

Your expert for biogas plants - reliably responsive

Tibor Kretschman

Head of International Project Development & Water Reuse

References biogas plants

Bioethanol, EGSB biogas reactor, ALMA BHU EGSB

Construction of an EGSB reactor with approx. 700 m³ and a COD load of 10,000 kg/d for the recovery of biogas from the production of bioethanol.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Biogas plant for Keszthely sewage treatment plant, Hungary, ALMA BHU GMR

Construction of a biogas plant for the sludge utilization of a municipal sewage treatment plant with an energy production of 2,000 kWh/d in Hungary.

Advantages of anaerobic wastewater treatment

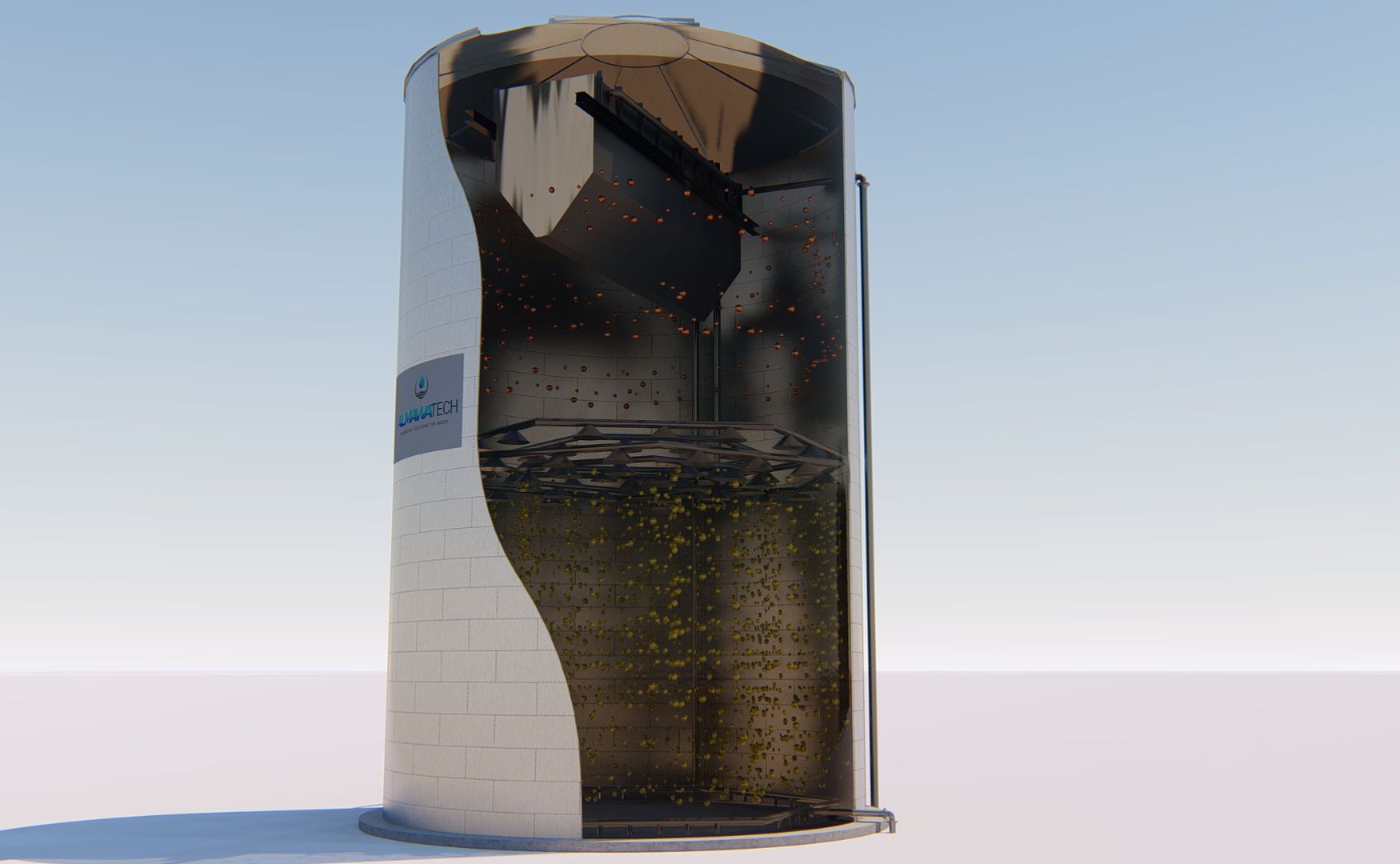

Advantages of our gas mixing reactor

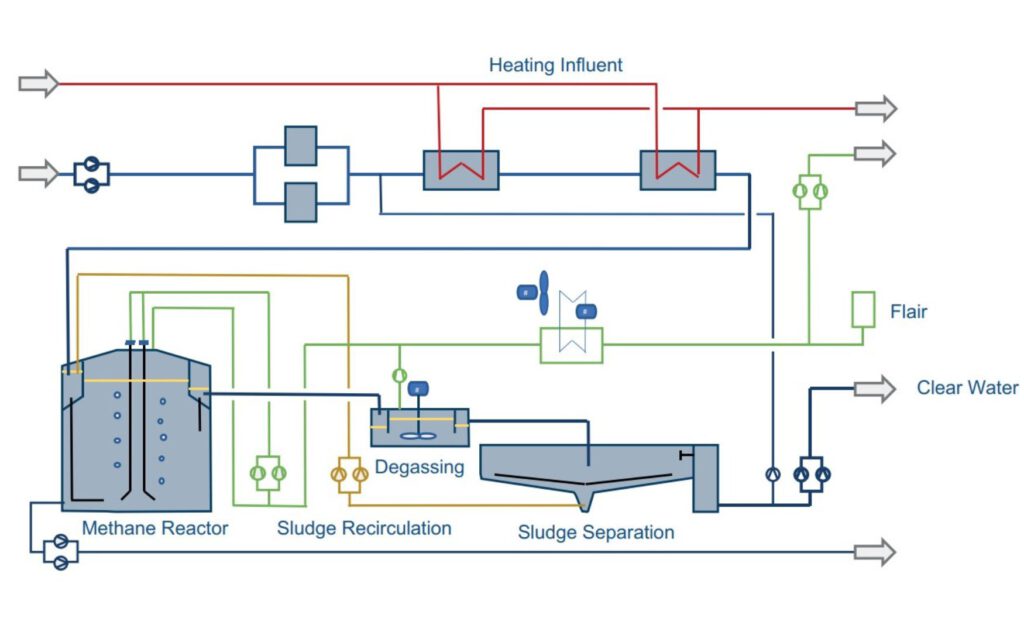

Process diagram: ALMA BHU GMR

Downloads

Tender text

Please contact our specialist for biogas plants: E-Mail

Similar products: Biogas from waste water

ALMA BHU BIO EGSB

Two-stage anaerobic reactor ALMA BHU BIO EGSB, which can be fed with a high COD load due to the two-stage biogas extraction.

ALMA BIO UASB

Single-stage anaerobic reactor ALMA UASB for the production of biogas from waste water from the food industry with reactor sizes up to 3,000 m³ and biomass recirculation.

Get in touch with us!

Tibor Kretschmann

Head of International Project Development & Water Reuse