Operating resources in industrial water and wastewater treatment are essential components that are used to optimize the functioning and efficiency of plants. They include a variety of chemicals, materials and technical aids that are necessary to control, improve or maintain water treatment processes. Operating fluids are used in various phases of water treatment and are crucial for protecting system components, preventing deposits and corrosion, and ensuring water quality.

Table of contents

Technical background and functionality

Operating equipment is used to support the chemical, physical and biological processes in water and wastewater treatment. Their functions range from the conditioning and purification of water to the maintenance and protection of systems. The targeted use of operating resources is crucial to ensure the operational capability of the systems, extend the service life of the system components and increase the overall efficiency of the water treatment processes.

Basically, operating resources can be divided into four main categories:

Precipitants and flocculants: These chemicals are used for solid-liquid separation in wastewater treatment. Precipitants, such as aluminum salts or iron(III) chloride, cause the formation of poorly soluble compounds that settle out as solids. Flocculants, such as polymers, support the process by enlarging the flocs formed so that they can be separated more easily.

Corrosion inhibitors: Corrosion inhibitors are essential in cooling and boiler water circuits to prevent corrosion of metallic surfaces. They form protective layers on the metal surfaces or change the water chemistry in order to slow down the corrosion processes.

Antiscalants & dispersants: Antiscalants prevent the formation of deposits (scaling) on surfaces, especially in membrane systems or boiler circuits. They work by modifying the crystal structures or by blocking the nucleation of undesirable solids such as calcium carbonate or calcium sulphate.

Biocides & bioinhibitors: These chemicals are used to control the growth of microorganisms in cooling water circuits and membrane systems. They prevent the formation of biofilms, which can lead to efficiency losses and corrosion.

Photo: Aeration tank with denitrification and nitrification for wastewater from the food industry (process: ALMA BHU BIO)

ALMA AQUA products

The ALMA AQUA product range from ALMAWATECH offers specialized treatment chemicals divided into four main categories: Wastewater Treatment, Cooling Water Treatment, Membrane Systems and Boiler Water Treatment. Each category includes customized chemicals developed for specific water treatment requirements.

1. ALMA AQUA waste water

The ALMA AQUA Wastewater-products include various chemicals for the treatment of wastewater produced in industrial processes. These products help to efficiently remove pollutants, reduce operating costs and improve wastewater quality. The chemicals for wastewater treatment are divided into the following categories:

Precipitants: Precipitants such as iron(III) chloride and aluminum sulfate are used to convert dissolved substances in wastewater (e.g. phosphates, heavy metals) into a solid phase. These solids can then be removed by sedimentation or filtration.

Flocculants: These polymers support the process of floc formation by combining small particles into larger flocs. This facilitates the separation of solids and improves the clarity of the treated water.

Neutralizing agents: Neutralizing agents such as sulphuric acid or sodium hydroxide are used to regulate the pH value of the wastewater. A neutral pH value is necessary to ensure the efficiency of the subsequent treatment processes and to guarantee compliance with limit values.

Conditioning agents: The conditioning agents in the ALMA AQUA wastewater series include the following products, for example:

- Bentonite: A natural clay mineral that is used as a sludge conditioner. It improves floc formation and increases the mechanical stability of the sludge. Bentonite is used particularly in sludge dewatering to reduce the water content in the filter cake.

- Hydrogen peroxide: A strong oxidizing agent used for the chemical oxidation of organic pollutants and for the removal of odors and colors in wastewater. It is also used for disinfection and to break down substances that are difficult to degrade.

- Sodium bisulphite: This chemical is used to dechlorinate wastewater, especially after disinfection with chlorine. Sodium bisulphite reacts with free chlorine and removes it before the water is discharged into the environment.

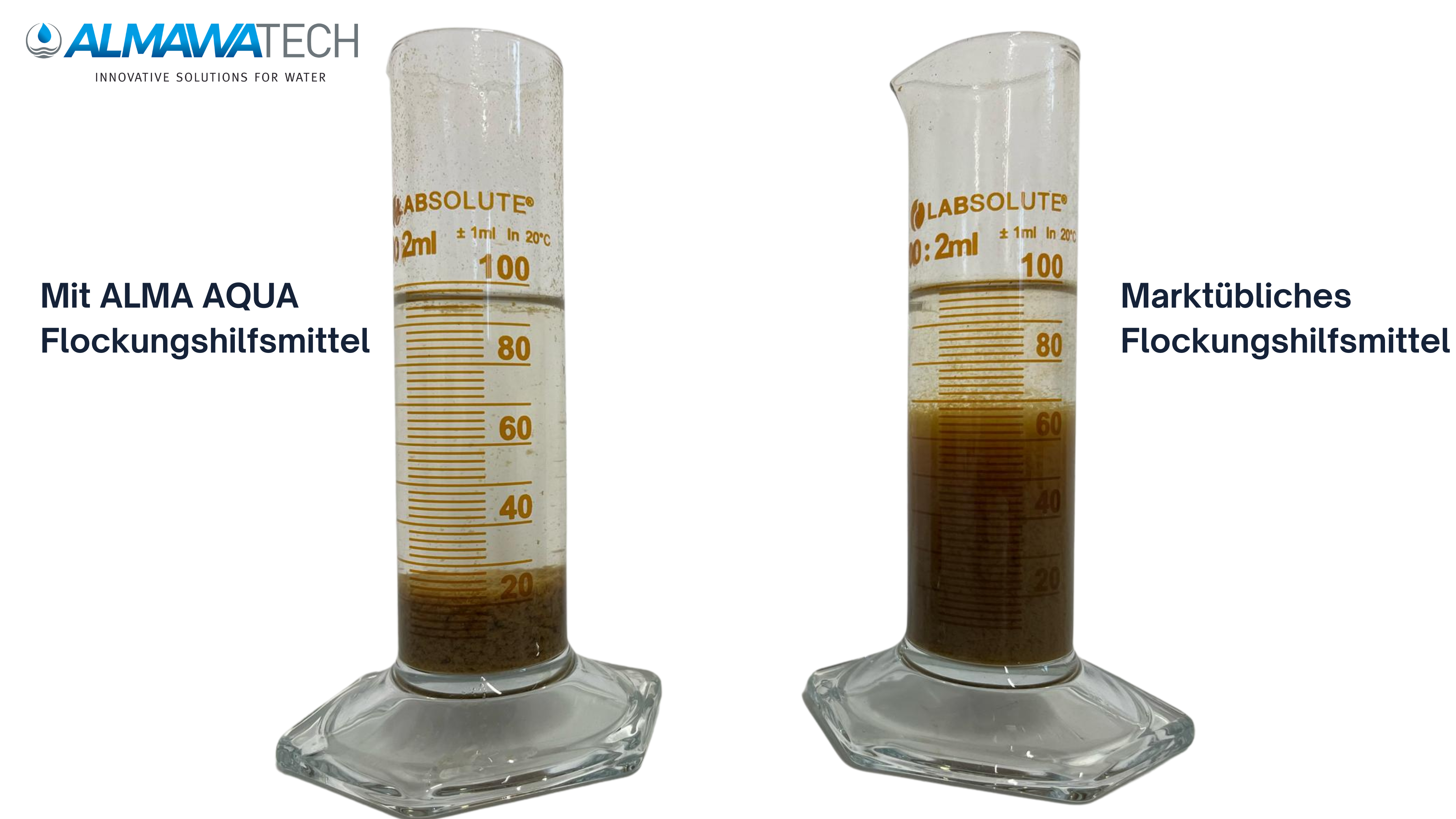

Photo: Comparison between commercially available flocculants and flocculants from the ALMA AQUA product range

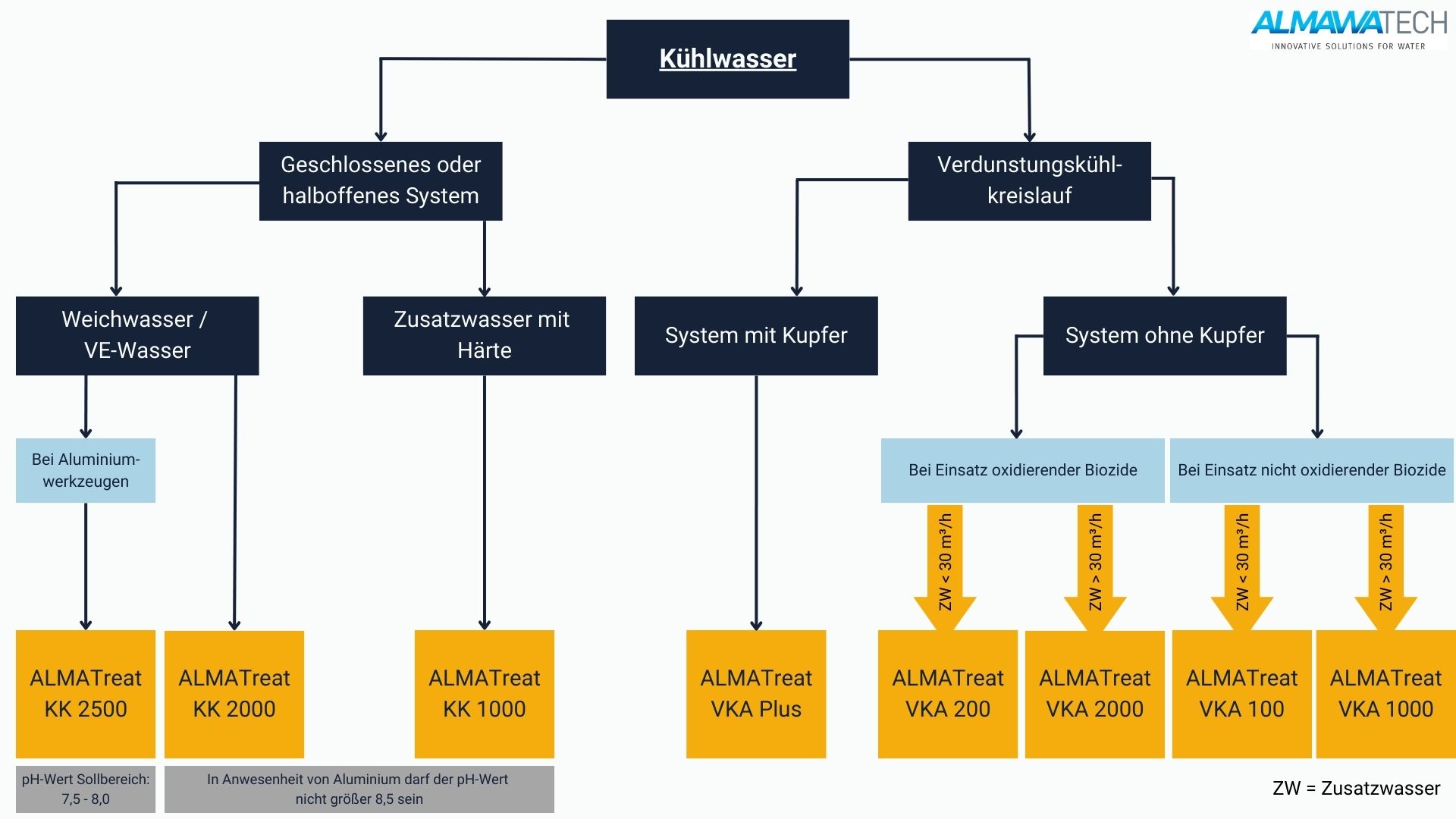

2. ALMA AQUA cooling water

Cooling water systems are particularly susceptible to corrosion, deposits and biofouling. The ALMA AQUA cooling water-products offer a comprehensive solution to ensure the operational stability and efficiency of cooling circuits:

Corrosion inhibitors: These chemicals prevent the decomposition of metal surfaces in contact with cooling water. They form a protective film on the metal surfaces to minimize oxidation and extend the service life of the system components.

Hardness stabilizers: These prevent the precipitation of hardness formers such as calcium and magnesium, which can lead to limescale deposits on heat exchangers and pipes. They help to maintain heat transfer efficiency and reduce maintenance costs.

Dispersants: Dispersants keep suspended particles in suspension to prevent deposits and increase the efficiency of cooling circuits. They work by separating particles from each other, preventing them from clumping together and settling on surfaces.

Biocides: To combat microorganisms that cause biofilms and fouling, the ALMA AQUA series contains oxidizing and non-oxidizing biocides that control microbial growth in cooling circuits and thus prevent corrosion and efficiency losses.

Photo: Product overview cooling water treatment (ALMA AQUA cooling water)

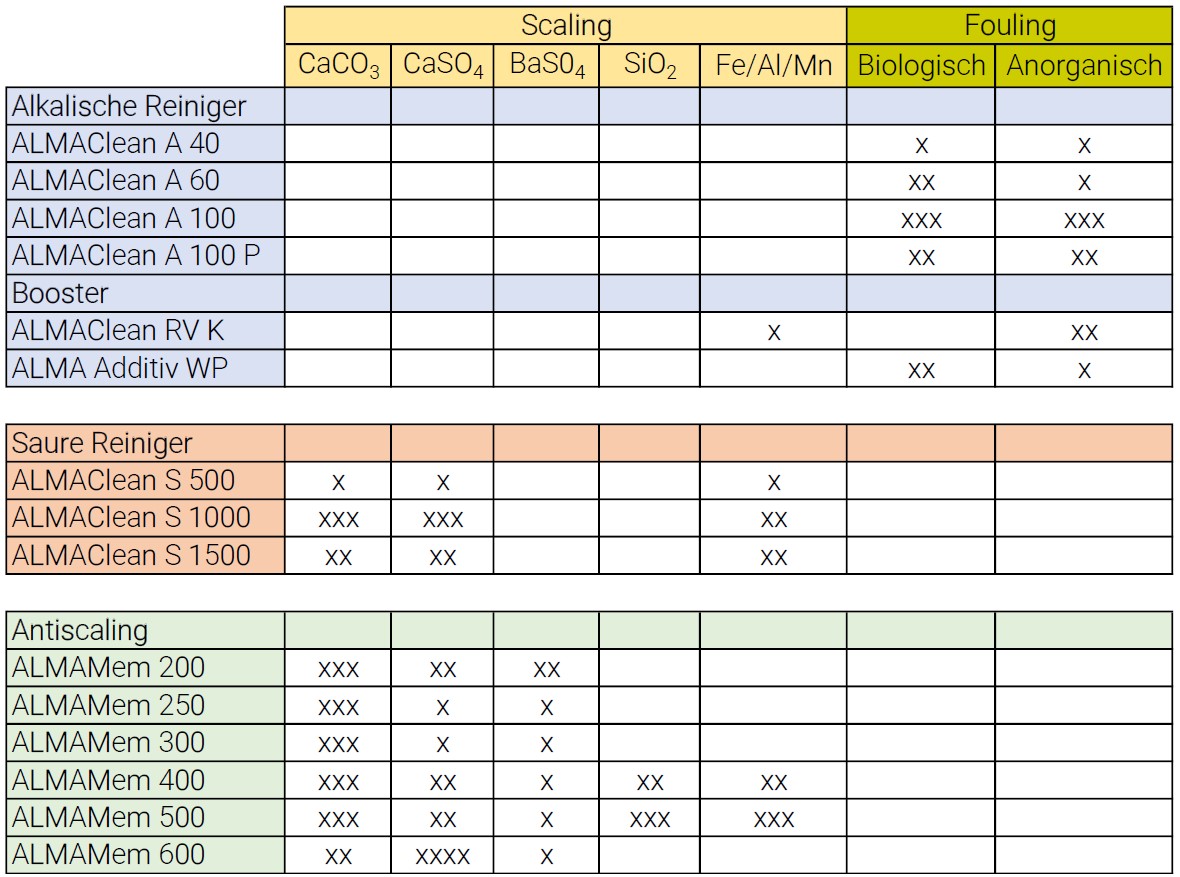

3. ALMA AQUA membrane

In membrane systems such as reverse osmosis (RO) and nanofiltration (NF), solids are often deposited (scaling) and biofouling occurs, which impairs the efficiency of the membranes. The ALMA AQUA membrane-products are specially designed to minimize these problems:

Acidic and alkaline membrane cleaners: These cleaners are used to remove deposits and impurities from the membranes. Acidic cleaners dissolve mineral deposits such as calcium carbonate, while alkaline cleaners break down organic deposits and biofilms.

Antiscalants: These prevent the formation of scaling on the membranes by inhibiting the crystallization of hardening agents and extending the service life of the membranes.

Boosters: These products enhance the effect of membrane cleaners and antiscalants and ensure even more efficient cleaning and deposit prevention.

Photo: Product overview of membrane cleaners and antiscalants (ALMA AQUA membrane)

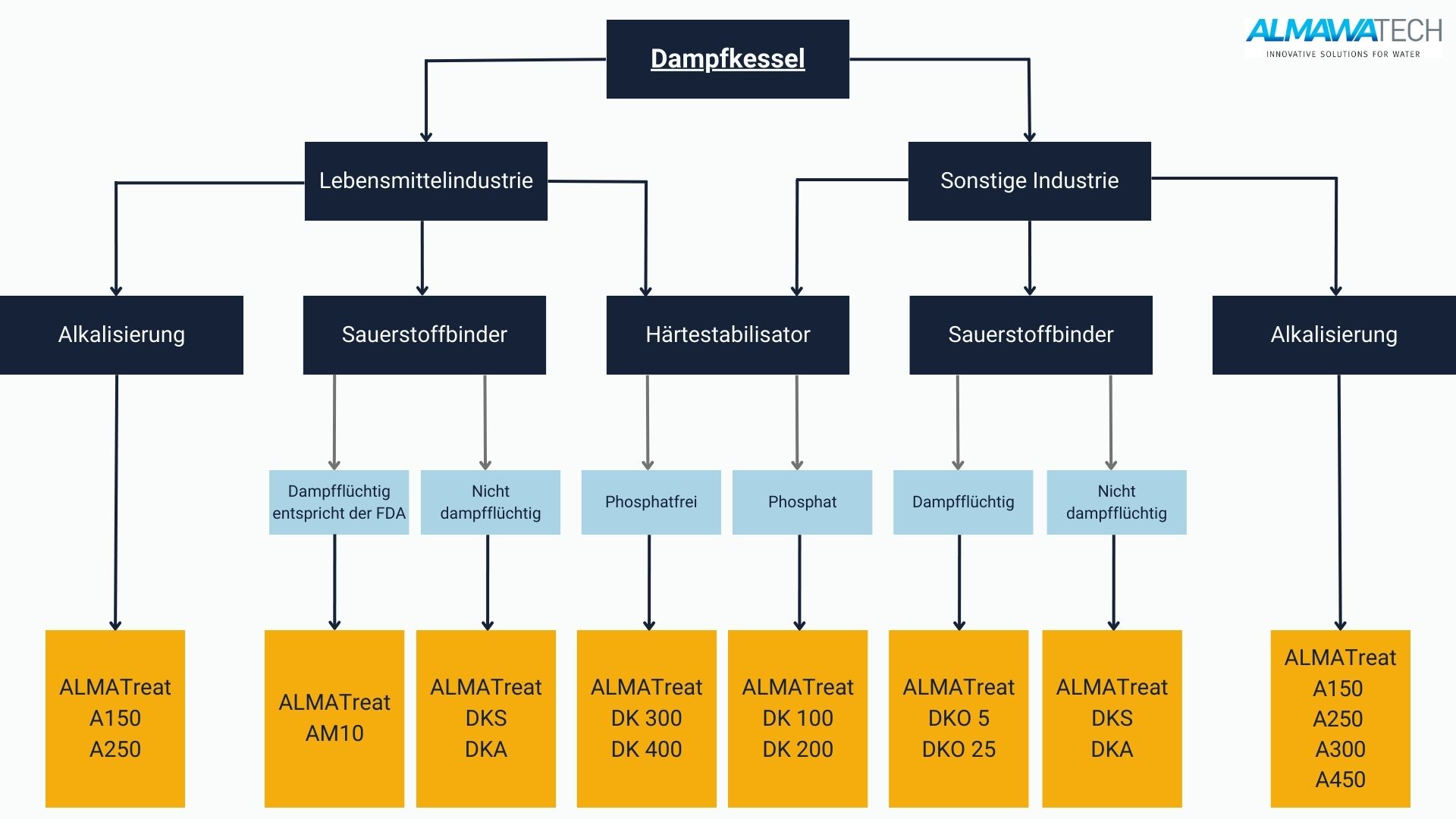

4. ALMA AQUA boiler

Boiler water systems require special chemicals to prevent corrosion, deposits and steam contamination. The ALMA AQUA Boiler-products offer comprehensive solutions for boiler water treatment:

Corrosion inhibitors: They prevent the oxidation of metal surfaces in the boiler systems and extend the service life of the system components.

Hardness stabilizers: These chemicals prevent the formation of scale and limescale deposits on the heat exchanger surfaces, which improves heat transfer efficiency and reduces energy consumption.

Defoamers: Defoamers prevent the formation of foam in the boiler water, which can lead to steam contamination and impair boiler operation.

Dispersants: They keep suspended solids in suspension in the water and prevent particles from settling on heat exchangers and pipes.

Oxygen binders: These remove dissolved oxygen from the water to prevent corrosion in boiler and condensate systems.

Alkalizing agents: These agents are used to increase the pH value in the boiler water and improve the conditions for corrosion prevention.

Biocides: Biocides that effectively combat microorganisms are used to prevent microbial corrosion (MIC) and fouling in the pipes and heat exchangers of boiler systems.

Photo: Product overview of various operating materials for steam boiler systems (ALMA AQUA boilers)

Conclusion

Operating equipment is indispensable in industrial water and wastewater treatment. They ensure the optimization of operating parameters, increase the efficiency of systems and contribute to compliance with legal requirements. ALMA AQUA products offer customized solutions for specific areas of application, from wastewater treatment to cooling water and boiler water treatment as well as membrane treatment. Through the targeted use of these chemicals, systems can be operated more efficiently, corrosion and deposits can be prevented and operating costs can be reduced.

For further information on our products, please feel free to contact us at any time!