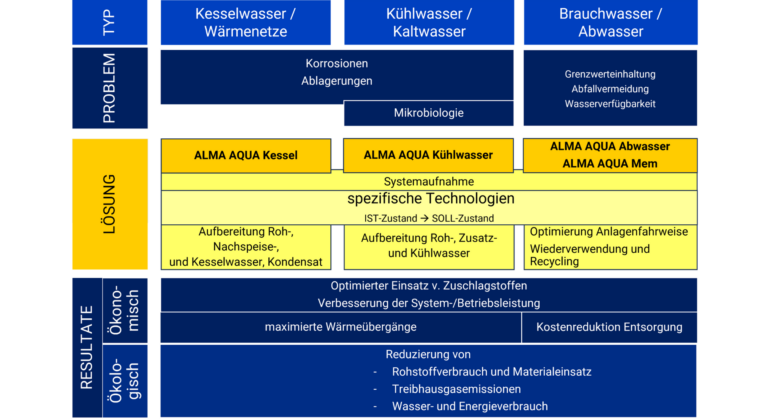

In industrial processes, water is far more than just an operating material - it is also a transport medium, reaction partner, energy source and safety element. This makes it all the more important to ensure the quality and stability of the respective water cycles in a targeted manner. This is precisely where ALMA AQUA process additives from ALMAWATECH come in: as a sophisticated product line for boiler, cooling, waste water and membrane systems.

Table of contents

ALMA AQUA - Process additives with a system

Our ALMA AQUA additives have been developed specifically for different types of water and areas of application. They are used to treat, stabilize and protect industrial water cycles and help to efficiently prevent corrosion, scale formation, biological contamination and process disruptions.

We also support our customers with comprehensive technical advice, on-site system surveys and regular water sampling and analysis. Our service is supplemented by self-sufficient monitoring and control with the ALMA Trol measuring, control and monitoring unit, including automated reporting, alarm messages by e-mail and simplified operating logbook management in accordance with the 41st BImSchV.

Our services are based on the applicable standards and guidelines such as

- 42nd BImSchV for compliance with microbiological parameters and legionella prevention

- VDI 2047 Sheet 2 for hygienically safe operation of evaporative cooling systems

- VDI/BTGA 6044 for quality assurance in water-bearing systems

- DIN EN 12953-10 for low-salt and high-salt operation in boiler systems

ALMA AQUA boilers - process reliability for steam and hot water boilers

Boiler systems are subject to high thermal and chemical loads. Our process additives protect boilers, pipelines and heat exchangers from deposits and corrosion, increase operational safety and improve energy efficiency:

- Alkalizer: pH control in the feed water

- Dispersants & hardness stabilizers: prevent coating formation due to dissolved salts

- Corrosion inhibitors: passivate metallic surfaces

- Oxygen binder: for oxygen-free water in the steam circuit

Our products meet the requirements of DIN EN 12953-10 with regard to low-salt and saline driving.

The result: longer service life, less maintenance, lower energy costs.

ALMA AQUA cooling water - stability for open and closed systems

In cooling systems, the main focus is on preventing corrosion, biological growth and incrustations. Our process additives are designed to optimally condition raw, make-up and circulating water:

- Corrosion inhibitors & hardness stabilizers: for metallic and mixed plant materials

- Dispersants: prevent solids adhesion

- Biocides & bioinhibitors: control microbiological growth and serve to prevent legionella

- System cleaners: remove organic and inorganic deposits

Our system also allows cooling water treatment that can be detected by sensors - for transparent control and a targeted response.

All processes used comply with the requirements of the 42nd BImSchV and VDI 2047 Sheet 2.

The targeted use of our products ensures long-term system protection, process stability and hygiene safety.

ALMA AQUA Wastewater - Efficiency in wastewater treatment

The chemical treatment of wastewater also requires precisely coordinated process additives in order to comply with legal limits, optimally condition the sludge and make operation economical:

- Flocculants & polymers: for improved particle binding

- Primary precipitant: for the targeted precipitation of phosphorus and metals

- Neutralizing agent: for pH adjustment in the drain or pre-process

- Defoamer: to prevent foam formation

- Sludge conditioner: for stable sludge parameters

Our ALMA AQUA wastewater products help to control the operation of your wastewater treatment plant safely, efficiently and in compliance with regulations.

ALMA AQUA Mem - Protection for modern membrane technology

Membrane systems react sensitively to scaling and chemical loads. Our ALMA AQUA membrane process additives protect your membrane systems against scaling, fouling and loss of performance:

- Substance-specific antiscalants: prevent the crystallization of poorly soluble salts

- Special cleaner: for acidic or alkaline membrane cleaning

- Active boosters: optimize the cleaning effect

- Preservatives: protect systems during downtime or storage

For you, this means longer running times, stable permeate quality and reduced cleaning effort.

Why ALMA AQUA?

Our process additives are not supplied off the shelf, but are tailored precisely to your system situation, water quality and operating objectives. In combination with our technical advice, they ensure the economical, safe and compliant operation of your water and wastewater technology.

Our range of services is supplemented by the use of modern dosing and measuring systems, corrosion protection measuring lines and pilot tests (on request) under real conditions. This enables complete monitoring of water quality and continuous optimization of chemical use.

Your advantages at a glance:

- Reduction in disposal costs

- Optimization of processes and operating costs

- Ensuring compliance with legal requirements

- Increasing work and plant safety

- Avoidance of unplanned downtime and maintenance costs

- Simplified operating logbook management in accordance with 41. BImSchV through automated reporting and alarm messages by e-mail

- Made in Germany production - short delivery times and reliable quality

- Fast, expert advice - on site, by phone or by e-mail

Whether thermal boiler, open cooling tower, industrial wastewater treatment plant or sophisticated membrane filtration - ALMA AQUA offers you the right support with customized process additives.

For further information on our products, please feel free to contact us at any time!

Our specialist for ALMA AQUA process additives:

Mr. Frank Kuntze