Task

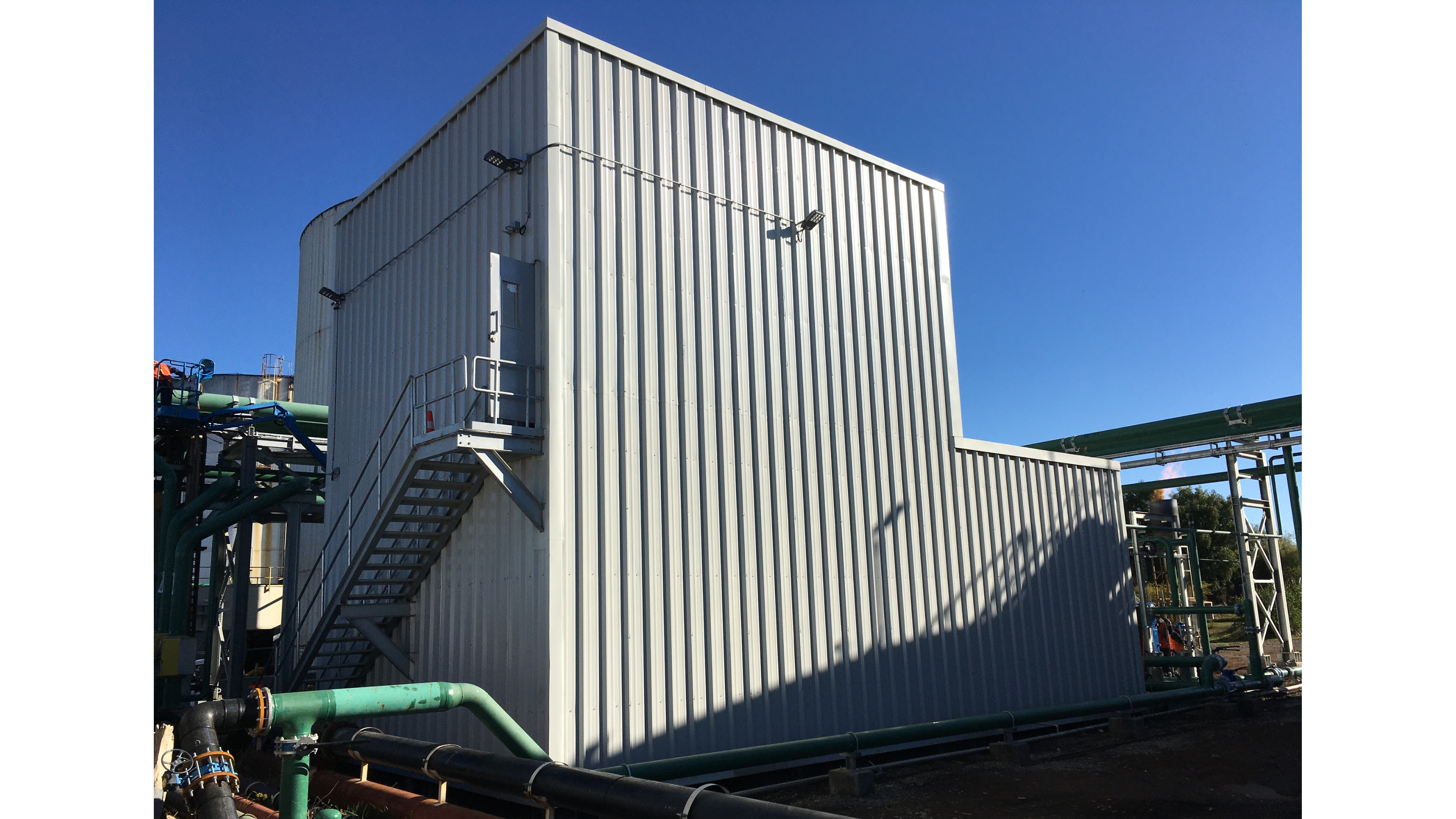

Increasing the existing wastewater treatment capacities with our ALMA BHU BIO biological treatment plant in Pemuco, Chile.

Design data

Waste water volume:

- 120 m³/h

BHU services

- Planning and engineering

- Delivery

- Installation

- Commissioning of the biological treatment plant

Solution & implementation

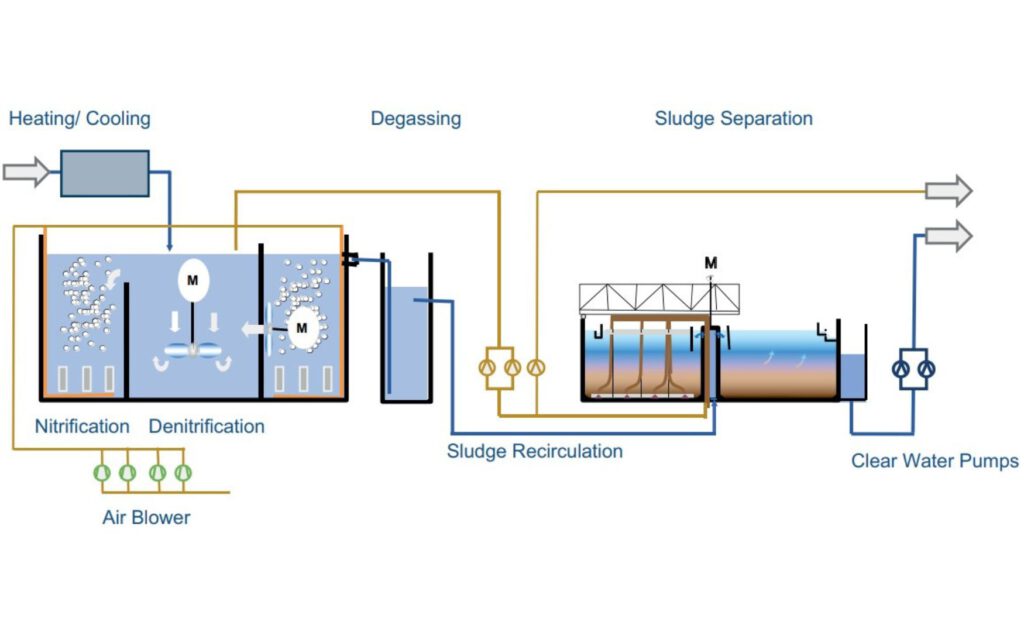

The biological water treatment plant in Pemuco is specially designed to meet the requirements of the sugar industry. It combines modern technologies for the removal of chemical oxygen demand (COD) and nitrogen. The system comprises various phases of denitrification and nitrification, which are integrated in a cascaded tank with subsequent degassing and clarification.

Process description

- Denitrification:

- The wastewater is pumped into the denitrification tank and mixed with sludge from the sedimentation tank and with the internal recirculation from nitrification. Phosphorus and additional carbon sources are added as required.

- The denitrification unit ensures the reduction of nitrate in anoxic conditions.

- Nitrification:

- The water flows internally into the nitrification section, where the decomposition of organic substances in the water and the conversion of ammonia and organic nitrogen into nitrate take place.

- Part of the nitrification stream is returned to denitrification, while the other part overflows by gravity into degassing.

- Degassing and sedimentation:

- The degassing unit removes dissolved gases from the water and ensures improved sedimentation properties of the sewage sludge.

Process diagram of our ALMA BHU BIO system

Main components of the biological treatment plant: ALMA BHU BIO

Process description

- Temperature, nutrient and COD management: Optimization of biological processes through precise control of operating conditions.

- Combined denitrification and nitrification stages: Effective removal of nitrogen and decomposition of organic compounds.

- Degassing and clarification: Ensuring water quality by removing gases and solids.

- Sludge management: Efficient handling and disposal of the resulting sludge.

Conclusion

With a capacity of 125 m³/h and efficient process control, our ALMA BHU BIO represents an energy-saving solution for wastewater treatment. The project expands our international reference portfolio and underlines our extensive expertise in wastewater treatment for the sugar industry.

Special thanks go to the dedicated project managers at BHU in Leonberg for their outstanding work in planning and implementing the plant. International projects always involve a great deal of time for communication and travel for on-site inspections and commissioning. The careful planning and precise execution by the team in Leonberg were crucial to the successful completion of this project.

For more information about our solutions and services, please feel free to contact us at any time.

References sugar industry

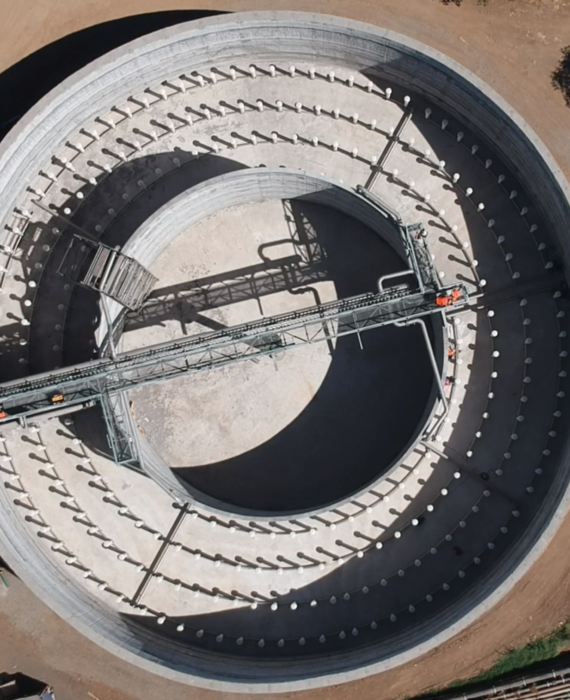

Sedimentation

Similar projects

Similar projects

Dairy Southern Germany, ALMA BioFil Compact

Vapor water treatment using biofiltration with a capacity of 600m3/d for a dairy in southern Germany. The vapor condensate is produced during the production of whey and lactose powder.

Eisbär Eis GmbH, Germany, ALMA NeoDAF HDED

We had the opportunity to supply and install our ALMA NeoDAF flotation system with a capacity of 16 m³/h as part of the construction of a new wastewater treatment plant for an ice cream manufacturer in northern Germany.

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Sternquell Brauerei GmbH, ALMA Neutra

Treatment of 360m3 of brewery wastewater per day with a pump shaft, solids separator and a neutralization system for Sternquell Brauerei GmbH.

Bäckerei Betz GmbH, Germany, ALMA NeoDAF Blue, grease separator

Treatment of 25m3 of bakery wastewater per day in a grease separator and a flotation plant for Bäckerei Betz GmbH.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Schweizer Zucker AG, Switzerland, degasser

A deaerator for a biogas plant between the lime separator and circular clarifier for Schweizer Zucker AG at the Frauenfeld site in Switzerland.

Südzucker AG, Belgium, ALMA BHU BiosS-Treat

A river water treatment plant (2 x 275 m³/h) for the production of process water, cooling water and boiler feed water in drinking water quality with reverse osmosis system and ion exchangers for the company Südzucker AG at the Wanze site in Belgium.