Task

Design, engineering, supply of special equipment, installation, commissioning of the deaerator for digested sludge from a biogas plant operated with sugar waste water.

Design data

Degasser performance:

- Sludge flow rate 140 m³/h

- Gas output 25 m³/h

Solution & implementation

Thanks to our expertise and references in the sugar industry, we were able to significantly increase the plant's biogas production. With a sludge throughput of 140 m³/h, our deaerator enables the production of an impressive 25 m³ of biogas per hour.

Our proven skills and experience in the sugar industry have enabled us to develop innovative solutions that contribute to a significant improvement in biogas yield. This is a clear example of our commitment to efficient and sustainable solutions.

References food industry, sugar industry

Similar projects

Dairy Southern Germany, ALMA BioFil Compact

Vapor water treatment using biofiltration with a capacity of 600m3/d for a dairy in southern Germany. The vapor condensate is produced during the production of whey and lactose powder.

Eisbär Eis GmbH, Germany, ALMA NeoDAF HDED

We had the opportunity to supply and install our ALMA NeoDAF flotation system with a capacity of 16 m³/h as part of the construction of a new wastewater treatment plant for an ice cream manufacturer in northern Germany.

Sugar industry, Chile, ALMA BHU BIO

Construction of a biological treatment stage with sedimentation stage for the treatment of 120 m³/h of wastewater from the sugar industry in Pemuco, Chile.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Sternquell Brauerei GmbH, ALMA Neutra

Treatment of 360m3 of brewery wastewater per day with a pump shaft, solids separator and a neutralization system for Sternquell Brauerei GmbH.

Bäckerei Betz GmbH, Germany, ALMA NeoDAF Blue, grease separator

Treatment of 25m3 of bakery wastewater per day in a grease separator and a flotation plant for Bäckerei Betz GmbH.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

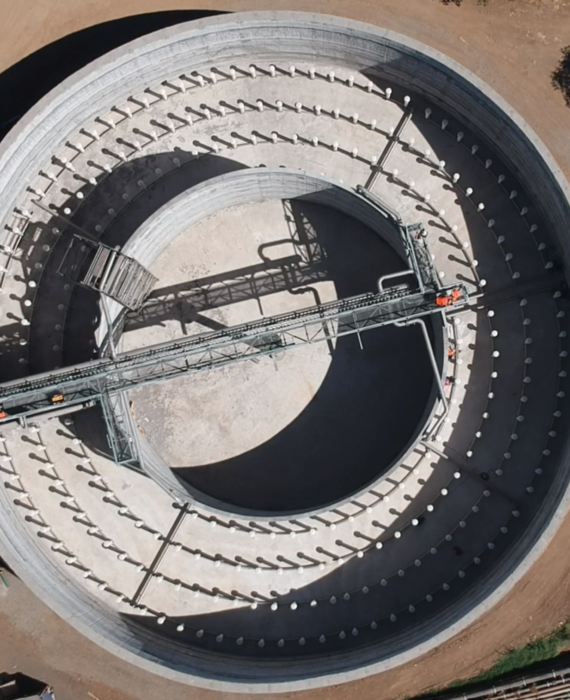

Schweizer Zucker AG, Switzerland, degasser

A deaerator for a biogas plant between the lime separator and circular clarifier for Schweizer Zucker AG at the Frauenfeld site in Switzerland.

Südzucker AG, Belgium, ALMA BHU BiosS-Treat

A river water treatment plant (2 x 275 m³/h) for the production of process water, cooling water and boiler feed water in drinking water quality with reverse osmosis system and ion exchangers for the company Südzucker AG at the Wanze site in Belgium.