Task

We successfully expanded the existing anaerobic plant for the production of biogas for a leading manufacturer of bioethanol. The aim was to utilize the wastewater streams generated in the production process - in particular vapour condensates and mixed wastewater - to generate energy and produce high-quality biogas.

As part of the project, we supplied our ALMA BHU EGSB reactor (Expanded Granular Sludge Bed)which was designed to meet the customer's project-specific requirements. It was designed for a load of 10,000 kg COD per day.

Specification and function of our EGSB reactor

COD load: 10,000 kg/d

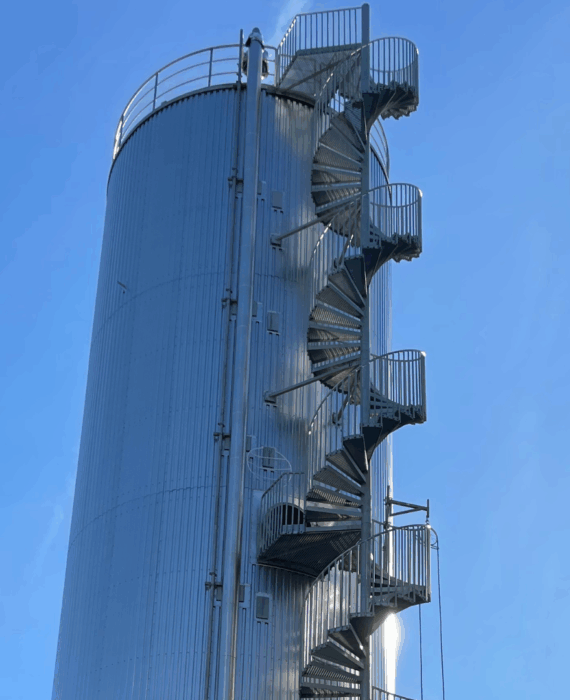

Reactor type: Welded EGSB reactor, project-specific design

Material: Stainless steel construction for maximum robustness and corrosion resistance

Volume: approx. 680 m³

Dimensions: Height 24 m, diameter 6 m

Construction: Two-stage design, equipped with spiral staircase, integrated recirculation and distribution system

Technological advantages

Special 3-phase separator: Efficient separation of gas, liquid and biomass

Circular gas collection system in the reactor head: no expansion tank required

Operational safety: no susceptibility to clogging and no foaming

High energy yield: Maximum biogas production thanks to optimized flow control

Customer benefits

With the integration of the new EGSB reactor the bioethanol producer:

Reliably treat production wastewater such as vapor condensates

Economically reduce high loads (10,000 kg COD/d)

Using biogas as renewable energy in your own processes

Increase operational safety and system stability

Conclusion

The successful implementation of this project demonstrates the advantages of the ALMA BHU EGSB reactor for industrial wastewater treatment in bioethanol production. The combination of a customized design, round gas collection system and innovative 3-phase separator made it possible to implement a robust and efficient solution that creates both ecological and economic added value.

References Chemistry & Bioethanol

Similar projects

Similar projects

Bioethanol, EGSB biogas reactor, ALMA BHU EGSB

Construction of an EGSB reactor with approx. 700 m³ and a COD load of 10,000 kg/d for the recovery of biogas from the production of bioethanol.

Sugar factory, Germany, ALMA BHU GMR

Construction of an anaerobic treatment stage or biogas plant for the recovery of energy from waste water from a sugar factory with a hydraulic capacity of 220 m³/h in Germany.

Sugar factory, Poland, ALMA BHU GMR

Construction of an anaerobic treatment stage and a biogas plant to generate energy from sugar production wastewater with a hydraulic capacity of 125 m³/h in Poland.

Südzucker AG, Ochsenfurt, ALMA BHU GMR, BIO

Treatment of sugar beet wash water in a biogas plant with pre-acidification and a COD load of 45,000 kg COD/d, for Südzucker in Ochsenfurt.

Biogas plant for Keszthely sewage treatment plant, Hungary, ALMA BHU GMR

Construction of a biogas plant for the sludge utilization of a municipal sewage treatment plant with an energy production of 2,000 kWh/d in Hungary.