A cracking plant, also known as a CP plant (chemical-physical plant), is a central process in industrial wastewater treatment that is used to remove emulsified oils, heavy metals, solids, AOX and other substances that are difficult to break down. The principle of the splitting plant is based on a combination of chemical precipitation, flocculation, neutralization and sedimentation in order to efficiently eliminate pollutants from the wastewater.

Splitting systems are primarily used in industries where contaminated process or waste water is produced, such as metal processing, surface treatment, the food industry and the petrochemical industry. Through the targeted use of chemicals and physical processes, the legal discharge limits can be reliably complied with.

Table of contents

How a splitting system works

The treatment of industrial wastewater in a splitting plant takes place in several coordinated steps:

1. wastewater collection and homogenization

The wastewater produced is first collected in buffer tanks and homogenized. This balances out strong fluctuations in concentration and pH, which could have a negative impact on the chemical splitting process.

2. neutralization

As many industrial wastewaters contain acidic or alkaline components, the pH value is first adjusted to an optimum range, typically between 6.5 and 8.5. This step is crucial, as chemical precipitation and flocculation only take place efficiently at certain pH values.

Alkaline neutralization:

- Acidic wastewater (low pH value) is neutralized by adding alkaline solutions such as caustic soda (NaOH) or milk of lime (Ca(OH)₂).

Acid neutralization:

- For alkaline wastewater (high pH value), sulphuric acid (H₂SO₄) or hydrochloric acid (HCl) is dosed.

Automatic pH control with inline pH sensors and dosing systems ensures precise and continuous adjustment of the pH value.

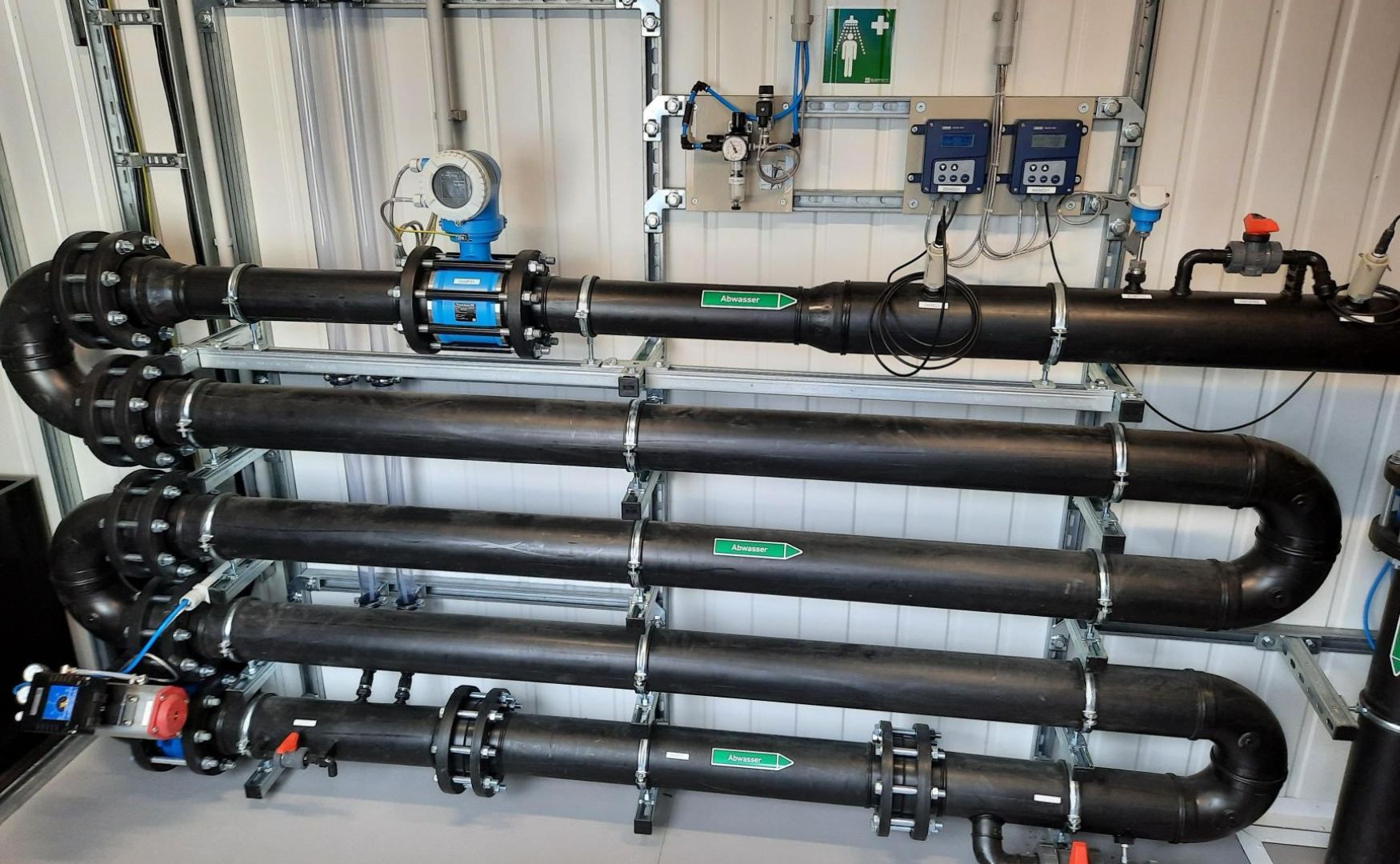

Photo: Reaction loop of the ALMA Neutra automatic neutralization system

3. chemical precipitation and flocculation

Chemical precipitation and flocculation form the heart of the splitting plant. In this step, the dissolved and colloidal pollutants are chemically converted into insoluble solids (flocs):

Felling:

- The addition of precipitants such as iron(III) chloride (FeCl₃), aluminum sulfate (Al₂(SO₄)₃) or milk of lime (Ca(OH)₂) leads to the formation of insoluble hydroxide compounds.

- In this process, heavy metal ions (e.g. Ni²⁺, Zn²⁺) are converted into poorly soluble hydroxides and separated as solids.

Flocculation:

- The addition of flocculants (organic or inorganic polymers) causes the formation of larger and more stable flocs, which are easier to sediment.

Intensive stirring ensures that the chemicals are evenly distributed and promotes the formation of flakes.

Photo: CP system ALMA CHEM MCW for the elimination of heavy metals, AOX, hydrocarbons and cyanides

4. sedimentation

The flocs sink in a sedimentation tank due to gravity and form the so-called sludge, which is separated from the purified liquid. The resulting sludge can then be dewatered and disposed of.

5. flotation

Another physical separation process that is often used in combination with chemical processes is flotation. Here, fine air bubbles are introduced into the wastewater, which adhere to the flocs and transport them to the surface, where they are skimmed off as sludge.

Photo: ALMA NeoDAF flotation plant

5. post-treatment (optional)

Depending on the discharge limits or if the wastewater is to be reused as process water, additional post-treatment may be required, e.g. by:

- Filtration:

- Gravel filter or activated carbon filter to remove residual suspended solids and organic compounds.

- Polishing:

- Fine filtration or ion exchange to achieve the highest purity requirements.

Photo: Our ALMA FIL multi-layer filters with downstream ALMA ION ion exchanger

Application areas of the splitting system

Splitting plants, also known as chemical-physical plants (CP plants), are versatile and play a decisive role in industrial wastewater treatment. They are used wherever heavily contaminated wastewater containing high concentrations of emulsified oils, heavy metals, AOX, phosphates, solids or organic residues (COD) is produced. The use of splitting plants enables companies to reliably comply with legal discharge limits, protect the environment and make operating processes more efficient.

1. metalworking industry

The metalworking industry produces wastewater that is heavily contaminated with heavy metals and other harmful substances. These are mainly produced in the following processes:

Electroplating:

During the surface finishing of metals, such as galvanizing, chrome plating or nickel plating, wastewater with high concentrations of heavy metals such as zinc (Zn), nickel (Ni) or chromium (Cr) is produced. These must be separated by chemical precipitation as sparingly soluble hydroxides to enable discharge into the wastewater system.Hardening plants:

Hardening plants produce wastewater that is contaminated with oil and grease residues as well as salts and heavy metals from the hardening processes. Splitting systems efficiently remove oil emulsions and heavy metals to purify the water.Mechanical processing:

Cooling lubricants and oils are used in processes such as drilling, milling, grinding or cutting. The wastewater often contains emulsified oils, solids and fine metal particles, which are effectively separated by chemical splitting and flocculation.

Treated pollutants: heavy metals, oils, greases, emulsions, solids, chromium, cyanide.

2. surface treatment

In surface treatment, metals are cleaned, coated or processed using chemical or electrochemical processes. This results in waste water that is contaminated with chemical residues as well as oils and greases. Typical processes include

Etching processes:

The chemical removal of metal layers produces waste water containing acids, alkaline residues and dissolved metal ions. These must be treated by neutralization and precipitation.Coating processes:

Processes such as painting, powder coating or the application of protective coatings generate waste water containing color pigments, resins, heavy metals and organic solvents.Cleaning processes:

Cleaning baths containing oil, grease and chemical residues are frequently used in surface treatment. Splitting systems can effectively treat these impurities and thus enable the water to be reused in the production cycles.

Treated pollutants: oils, greases, heavy metals, chemical residues, pigments, solvents, AOX.

3. food industry

The food industry produces wastewater with a high proportion of organic contamination, fats and oils. This wastewater is mainly produced during processing, cleaning and rinsing in the following areas:

Slaughterhouse and meat processing:

Wastewater contains high quantities of animal fats, proteins and blood, which lead to a high organic load.Dairy industry:

Milk processing produces wastewater containing fat, whey residues and organic substances that must be treated before discharge or reuse.Beverage industry:

In breweries, wine press houses and juice production, wastewater contains sugar, solids and organic residues.

Splitting plants enable the separation of fats, oils and suspended solids through precipitation and flocculation and reduce the chemical load of the water (e.g. COD and BOD values).

Treated pollutants: fats, oils, organic residues, proteins, solids.

4. petrochemical industry

In the petrochemical industry, waste water is produced that is contaminated with oils, emulsions and hydrophobic compounds. Splitting systems are used here in the following areas in particular:

Oil processing and refineries:

The wastewater contains emulsified oils, hydrocarbons and solids, which are efficiently removed by chemical splitting and flocculation.Tank cleaning:

Cleaning tanks or tankers produces oily and chemically contaminated wastewater, which is also treated using chemical-physical processes.

The combination of precipitation, flocculation and sedimentation enables the effective removal of oils and solids so that the water can either be reused or discharged in compliance with the law.

Treated pollutants: Emulsified oils, hydrocarbons, solids, AOX.

5. paint and plastics industry

The paint and plastics industry produces wastewater that is particularly heavily contaminated with color pigments, solvents and polymer residues. The most important areas of application include

Paint and varnish production:

Wastewater containing heavy metals, paint particles and chemical solvents is produced here.Plastic recycling:

When plastic waste is washed and cleaned, impurities, organic residues and chemical additives are flushed into the wastewater.

Chemical precipitation and flocculation can reliably remove these pollutants and separate the particles in the form of sludge.

Treated pollutants: paint and varnish residues, solvents, organic additives, heavy metals.

Photo: CP system ALMA BHU LHPS with high-performance lamella separator

Advantages of a splitting system (CP system)

Efficient pollutant removal:

- High separation efficiency for heavy metals, oils, greases and other pollutants.

Flexibility:

- Adaptable to different wastewater compositions through targeted selection of chemicals.

Compliance with legal limits:

- Reliable compliance with the requirements of the German Wastewater Ordinance (AbwV).

Compact design:

- Space-saving integration into existing system structures.

Economic efficiency:

- Low operating costs thanks to effective use of chemicals and sludge reduction.

Challenges and optimization potential

- Chemical consumption:

- Precise dosing of precipitants and flocculants is necessary to avoid overdosing and reduce costs.

- Sludge accumulation:

- Optimized precipitation processes reduce the amount of sludge and facilitate disposal.

- Process monitoring:

- Automated pH measurement and turbidity monitoring improve process stability.

Conclusion

Cracking plants (CP plants) are an indispensable part of industrial wastewater treatment. Through the targeted combination of neutralization, chemical precipitation and flocculation, they enable the efficient removal of heavy metals, oils, AOX, cyanides and other pollutants. Their versatility and high separation efficiency make them the preferred choice in many industries that produce contaminated wastewater.

With precise control, optimal use of chemicals and downstream sludge treatment, splitting systems ensure that legal limits are adhered to and operating costs are minimized. They therefore make a significant contribution to resource conservation, process reliability and environmental compatibility in modern water technology.

For further information on our products, please feel free to contact us at any time!