Post-treatment is a crucial part of industrial water and wastewater treatment, ensuring that water meets the desired quality parameters before it is discharged into downstream processes, the water cycle or the environment. It serves as a supplementary or final stage that removes residual impurities that have not been sufficiently eliminated by previous treatment processes. This stage is particularly important for applications with high water quality requirements, such as in the food, pharmaceutical or electronics industries, as well as for compliance with strict environmental regulations for wastewater disposal.

The following describes in detail which technologies and processes are used in post-treatment, which challenges they address and how they can be integrated into the overall systems of industrial water technology.

Table of contents

Goals of the follow-up treatment

Post-treatment has several specific objectives, which can vary depending on the application:

Improvement of water quality:

Removal of residual impurities such as fine particles, dissolved salts, organic substances and microorganisms.Ensuring compliance with limit values:

Treatment of wastewater to meet legal or industry-specific requirements, especially in sensitive areas such as drinking water treatment or wastewater discharge.Preparation for specialized applications:

Production of high-purity water for industrial processes, e.g. in the electronics or pharmaceutical industry, where low conductivity and high purity are required.Conservation of resources:

Recovery and recycling of water and nutrients to reduce waste water and fresh water consumption.

Typical post-treatment technologies

Post-treatment comprises a variety of technologies that can be used individually or in combination, depending on requirements.

1. filtration technologies

How it works:

The water passes through a filter bed consisting of different layers of filtration materials such as sand, anthracite and granulate. Coarse suspended particles are retained in the upper layers, while finer particles are caught in deeper layers.Advantages:

- Removal of particles up to 20 µm in size.

- High flow rates and easy backwashability.

Application:

- Pre-treatment before membrane systems.

- Reduction of turbidity in wastewater and process water streams.

How it works:

Ultrafiltration membranes remove particles, microorganisms and viruses from water by acting as a physical barrier. The pore size is typically between 0.01 and 0.1 µm.Advantages:

- Removal of bacteria and viruses.

- Increased efficiency of downstream membrane systems by reducing fouling.

Application:

- Treatment of surface water for industrial processes.

- Polishing of biologically treated wastewater before discharge or reuse.

Photo: Our ALMA BHU SMF sand and multi-layer filters in concrete construction

2. membrane technologies

How it works:

The water is forced under high pressure through semi-permeable membranes that retain dissolved salts, organic substances and trace substances.Advantages:

- Reduces the conductivity to values below 50 µS/cm.

- Removes over 99 % of dissolved salts and organic compounds.

Application:

- Production of high-purity water for the electronics, pharmaceutical and food industries.

- Water recycling by returning waste water to the process cycle.

How it works:

Similar to reverse osmosis, but with a larger pore size, which removes divalent ions such as calcium and magnesium, while monovalent ions such as sodium are retained to a lesser extent.Advantages:

- Efficient water softening.

- Lower energy consumption compared to RO.

Application:

- Reduction of hardness formers in the water.

- Pre-treatment for RO systems.

Photo: Our ALMA Osmo Process reverse osmosis system

3. oxidation process

How it works:

Ozone (O₃) is introduced into the water, where it has an oxidizing effect on organic compounds and microorganisms.Advantages:

- Effective against poorly degradable organic compounds.

- No chemical residues, as ozone decomposes into oxygen.

Application:

- Disinfection of drinking water.

- Degradation of trace substances such as pharmaceuticals and pesticides.

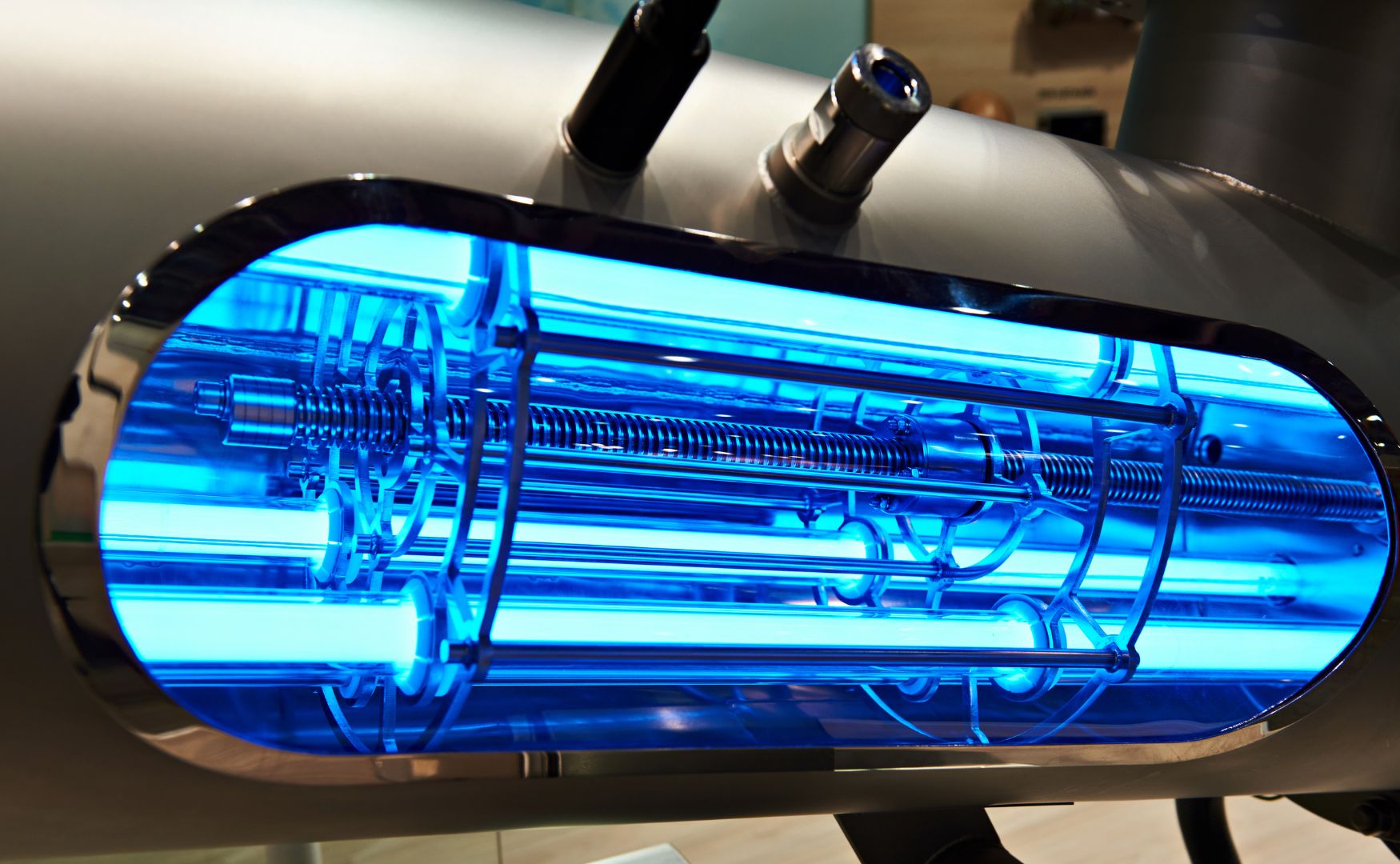

How it works:

UV radiation destroys the DNA of microorganisms, preventing them from multiplying.Advantages:

- Chemical-free process.

- No residues or by-products.

Application:

- Disinfection of drinking and process water.

- Polishing step after biological treatment.

Advanced Oxidation Processes (AOPs)

How it works:

Combination of UV radiation, ozone and hydrogen peroxide to form hydroxyl radicals, which oxidize highly reactive organic substances.Advantages:

- Degradation of poorly degradable organic compounds.

- Efficient even with low concentrations of pollutants.

Application:

- Treatment of wastewater from the chemical and pharmaceutical industries.

- Removal of odors and flavors in drinking water.

Photo: UV oxidation system ALMA OXI UV with dosing of hydrogen peroxide to form OH radicals

4. activated carbon adsorption

How it works:

Activated carbon filters bind organic molecules, trace substances and dissolved gases through adsorption. The large specific surface area of the activated carbon (up to 1,000 m²/g) makes it particularly efficient.Advantages:

- Removal of trace substances such as pesticides, chlorine compounds and heavy metals.

- Improves the smell and taste of the water.

Application:

- Polishing step after biological or physical-chemical treatment.

- Removal of pollutants in drinking water treatment.

Photo: Our ALMA FIL multi-layer filters with downstream ALMA FIL AK activated carbon filter

5. ion exchange

How it works:

In ion exchanger systems, dissolved ions are replaced by functional groups in the exchanger material. Anion and cation exchangers can be combined to produce completely demineralized water.Advantages:

- Precise removal of specific ions.

- Production of demineralized water for sensitive applications.

Application:

- Softening and demineralization of water.

- Removal of nitrates, sulphates and heavy metals.

Photo: ALMA ION ion exchanger system with upstream ALMA FIL multi-layer filter

Post-treatment of wastewater

Different post-treatment processes are available for wastewater treatment, depending on the composition and desired objective.

1. recovery of nutrients:

- Chemical precipitation and stripping process for the recovery of phosphorus and nitrogen.

- Areas of application: Fertilizer production, sustainable wastewater management.

2. water recycling:

- Biofiltration and reverse osmosis for the treatment of wastewater for reuse in production cycles.

- Typical example: recycling of cooling water or process water.

3. compliance with discharge limits:

- Downstream filtration or oxidation to remove trace substances, metals or nutrients in order to meet environmental requirements.

Challenges in follow-up treatment

Post-treatment is associated with specific challenges that require careful planning and regular optimization:

- Residual impurities:

- Dissolved organic and inorganic substances that are difficult to remove may require additional polishing steps.

- Membrane fouling:

- Biofouling or scaling in membrane systems reduces efficiency.

- Solution: Use of antiscalants and regular CIP cleaning.

- Energy consumption:

- High-tech processes such as RO and UV oxidation require high energy input.

- Solution: Integration of energy recovery systems.

- Costs:

- Post-treatment steps can be cost-intensive, especially with high water treatment requirements.

- Solution: Process optimization and module combinations to reduce operating costs.

Conclusion

Post-treatment is an indispensable stage in water and wastewater treatment that makes a decisive contribution to compliance with quality standards and environmental regulations. Through the targeted use of modern technologies such as activated carbon filtration, oxidation and membrane technologies, even the most demanding requirements can be met. In combination with water recycling strategies, secondary treatment not only contributes to the conservation of natural resources, but also to cost optimization and sustainability in industrial water management.

For further information on our products, please feel free to contact us at any time!