River water treatment is essential for industries with high water requirements in order to obtain process water from surface water sources such as rivers or lakes in an efficient and environmentally friendly manner. This treatment comprises several steps that are coordinated with each other to prepare the water for the specific requirements of industrial use.

When is river water treatment worthwhile?

River water treatment makes particular economic and ecological sense when:

- Large quantities of water are required.

- Access to fresh water sources is limited or expensive.

- Legal requirements for resource conservation and wastewater treatment must be met.

Industries with river water treatment plants

- Paper mills: Use large quantities of water for production and use river water treatment to cover fresh water requirements.

- Chemical and petrochemical companies: Treat river water for use as cooling and process water.

- Power plants: Use river water for cooling, especially in circulation systems.

- Food and beverage manufacturers: Rely on high-purity water quality from river water for rinsing and cleaning processes.

Table of contents

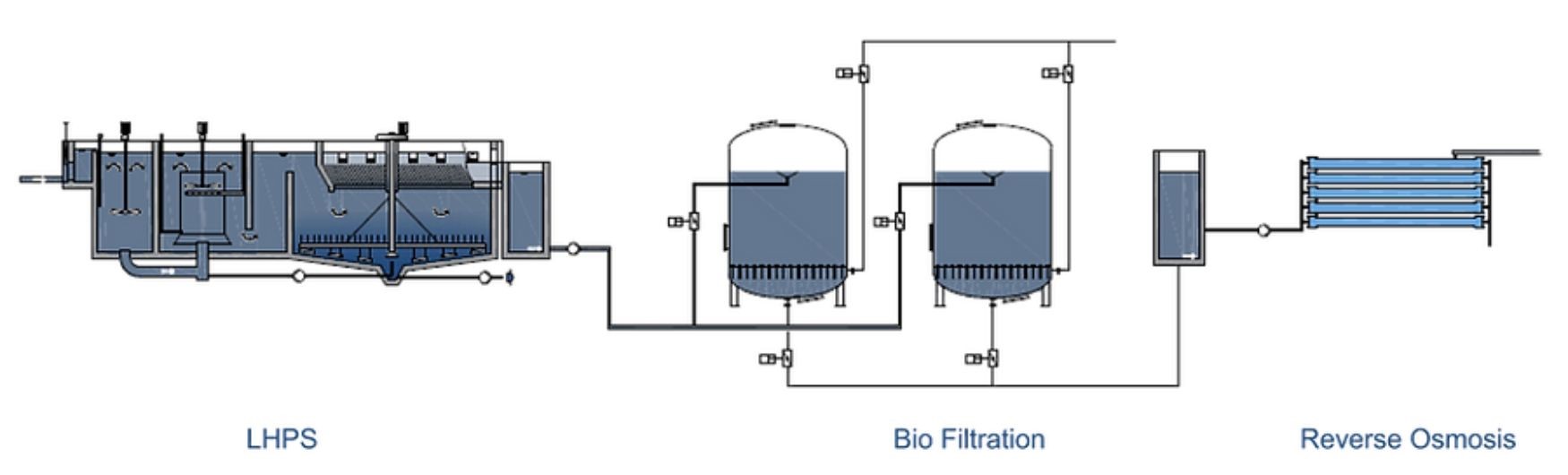

1. pre-treatment: precipitation and flocculation with ALMA BHU LHPS

The ALMA BHU LHPS system is a high-performance process for the pre-treatment of river water. In this step, undissolved substances such as suspended solids, sediments and organic impurities are removed through precipitation and flocculation effectively removed. Precipitants such as iron or aluminum salts and flocculants are used to bind the particles into larger flocs that can be easily settled or filtered.

Technical background:

- Precipitation: Chemical reaction in which dissolved substances are converted into insoluble compounds.

- Flocculation: Aggregation of the particles formed into larger flocs.

This process is crucial to protect the downstream systems from contamination.

Photo: High-performance honeycomb separator for separating the flakes from our CP system ALMA BHU LHPS

2. biological treatment: carbon elimination and nutrient reduction with ALMA BHU BAF

The ALMA BHU BAF technology offers biologically activated filtration that has been specially developed for carbon elimination as well as nitrification and denitrification. This stage is particularly important for removing organic impurities and nitrogen compounds from the water.

How it works:

- Nitrification converts ammonium to nitrate, while denitrification converts nitrate into nitrogen gas, which escapes into the atmosphere.

- The degradation of organic compounds significantly reduces the risk of biofouling in downstream reverse osmosis systems, which extends the service life of the membranes and minimizes the consumption of chemicals.

Photo: Our ALMA BHU BAF biofiltration system for a river water treatment plant with a capacity of 2,200 m3/h

3. reverse osmosis: ALMA BHU BiosS-Treat

The ALMA BHU BiosS-Treat reverse osmosis system is the final stage of water treatment. This process uses semi-permeable membranes to almost completely remove dissolved salts, heavy metals and organic pollutants. The result is ultra-pure process water that meets the specific requirements of industrial production.

Technical advantages:

- High retention rates of ions and impurities.

- Reduction of biofouling through effective pre-treatment in the previous stages.

Photo: Reverse osmosis system ALMA BHU BiosS-Treat one of our realized river water treatment plants

4. filtration and ion exchange with ALMA FIL and ALMA ION

Alternatively, river water treatment can also be realized using a combination of fine filtration with PAC dosing (ALMA FIL) and in combination with ion exchangers.

The ALMA ION system (cation and anion exchanger) then ensures the targeted removal of ions such as calcium, magnesium and chlorides. Softening the water prevents deposits in downstream processes.

Conclusion

River water treatment with ALMAWATECH technologies offers a comprehensive solution for the provision of high-quality process water from surface water. The combination of chemical, biological and physical processes enables the sustainable and cost-efficient use of water resources. Our customized systems such as ALMA BHU LHPS, ALMA BHU BAF, ALMA FIL, ALMA ION and ALMA BHU BiosS-Treat ensure that each stage of water treatment is optimally tailored to the individual requirements of our customers.

For further information on our products, please feel free to contact us at any time!

Photo: Process diagram of a modern river water treatment plant with precipitation/flocculation (ALMA BHU LHPS), biofiltration (ALMA BHU BAF) and reverse osmosis (ALMA BHU BiosS-Treat)