The German Environment Agency and the ECHA (European Chemicals Agency) have submitted a dossier to the European Commission for the restriction of the manufacture, use and placing on the market of PFAS. A decision by the EU member states is expected in 2025. A restriction under Annex XVII of the REACH Regulation has significant implications for various sectors of industry.

This article explains what PFAS are, what damage they cause, which industries are affected by regulation and how PFAS are removed from wastewater.

Table of contents

What are PFAS and why are they used?

PFAS is the term for per- and polyfluorinated chemicals. There are currently around 10,000 different PFAS substances. The most frequently found PFAS substance groups are the perfluorinated sulfonic acids such as perfluorooctane sulfonic acid (PFOS) and the perfluorinated carboxylic acids perfluorooctanoic acid (PFOA). PFOS and PFAS are also used as lead parameters for tests in wastewater and drinking water.

PFAS are not of natural origin and have only been produced since the 1940s.

The most commonly known products containing PFAS are coated frying pans, fire-fighting foam, cosmetics, clothing and food packaging. Due to the water, dirt and grease repellent properties of PFAS, they have been used in various industries since the 1940s. One of the main industrial entry paths is waste water from the surface treatment of metals (e.g. various hydraulic components, pumps, motors, cylinders) and plastics (e.g. seals, hoses, pipes, valves, coatings).

Why PFAS are a cause for concern

PFAS are extremely long-lived compounds and have been given the nickname "forever chemicals". Due to their extreme longevity, the substances have enough time to spread across our planet via waterways and air currents. As PFAS are not biodegradable, they accumulate in humans and animals.

Few causal links have yet been found between PFAS and specific diseases. However, some studies show a correlation between increased PFAS concentrations in the body and the occurrence of diseases such as cancer, type II diabetes, chronic inflammation and a general weakening of the immune system.

Pending regulations for PFAS

A large number of PFAS are on the candidate list of XIII of the REACH Regulation, as they are classified as PBT (persistent, bioaccumulative, toxic) or vPvB (very persistent, very bioaccumulative) substances. An entry in the candidate list results in an obligation to provide information for suppliers and information rights for consumers for products containing more than 0.1% by mass of PFAS.

As a result, these substances can be entered in Annex XIV of the REACH Regulation. The annex is also known as the list of substances subject to authorization. For further use of PFAS in industrial processes, companies will then require an authorization from the European Commission. Here is a link to the current list of substances subject to authorization: https://echa.europa.eu/de/authorisation-list

Last year, the German Environment Agency (UBA) and the ECHA (European Chemicals Agency) scientific committees for risk assessment examined the legal requirements for a restriction under the REACH Regulation and forwarded them to the European Commission. The restriction covers the manufacture, use and placing on the market of PFAS.

The next step is a vote by the EU member states on a restriction in accordance with Annex XVII of the REACH Regulation. A decision is expected in 2025.

For more detailed information on the areas of application of the restriction dossier, the exemptions and the consequences of a broad restriction, you can read the dossier here: ANNEX XV RESTRICTION REPORT, PROPOSAL FOR RESTRICTION, Per- and polyfluoroalkyl substances (PFASs)

Process for removing PFAS from wastewater and process water

Let us now turn to the solutions for removing PFAS from wastewater and process water. Only a small proportion of PFAS are removed from wastewater using conventional treatment methods. This means that industrial and municipal operators of wastewater treatment plants are equally affected by the problem.

In principle, there are four different methods for removing PFAS from wastewater and process water. None of these methods are biological in nature, as PFAS are hardly biodegradable.

Reverse osmosis systems for the removal of PFAS

Photo: ALMA OSMO Process(to the reference plant)

In 2024, ALMAWATECH successfully commissioned one of the first multi-stage reverse osmosis plants for the elimination of PFAS from wastewater. The plant was built in a closed stainless steel construction with nitrogen inertization and equipped with 73 (!) measuring points.

Reverse osmosis systems are widely recognized as the most effective method for removing PFAS from wastewater and process water. Thanks to a multi-stage system design, over 99.9% of all PFAS can be removed. However, 99.9% of all other trace substances and minerals are also removed from the water.

Especially in the field of drinking water treatment, reverse osmosis systems are used almost as standard for the removal of PFAS. The disadvantage of using reverse osmosis systems in wastewater applications is that the wastewater must be pretreated accordingly. An example of a pre-treatment stage is our ALMA BioFil Compact.

Ion exchanger for the specific removal of PFAS

Photo: ALMA ION (to the product)

Ion exchangers are special cation and anion resins that are usually stored in GRP tanks. The ion exchangers are capable of very specifically removing PFAS from wastewater and process water.

As with reverse osmosis systems, the wastewater to be treated must be pre-treated accordingly. Another feature compared to reverse osmosis systems is that specific groups of PFAS can be removed and the ion exchangers therefore work selectively.

Activated carbon for the removal of PFAS

Photo: ALMA FIL AK (to the product)

Granulated activated carbon (GAC) filter systems are successfully used to remove various trace substances such as drug residues, refractory COD, AOX, heavy metals and PFAS. The PFAS are removed by adsorption onto the activated carbon.

It has been shown that long-chain PFAS such as PFOA or PFOS adsorb particularly well. Short-chain PFAS such as perfluorobutane sulfonic acid (PFBS) are less well adsorbed. One disadvantage of using activated carbon to remove PFAS is disposal. Depending on the concentration of PFAS in the water to be treated, the activated carbon is quickly used up and must be disposed of.

Advanced Oxidation Process (AOP process) for the removal of PFAS, e.g: UV oxidation and Fenton process

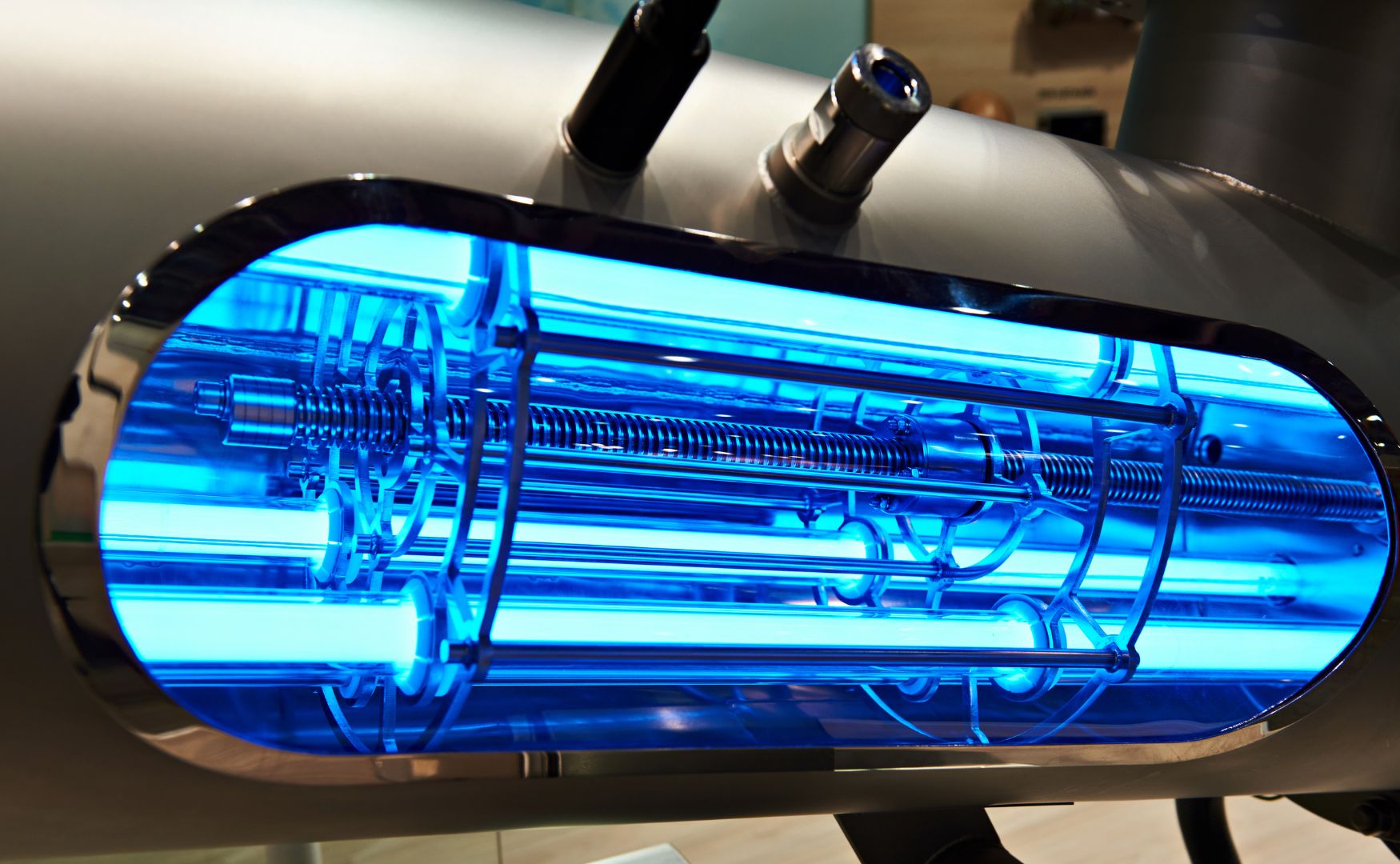

Photo: ALMA OXI UV (to the product)

The oxidation of PFAS using the advanced oxidation process is a field that has received little attention to date. However, it has already been shown that AOP processes such as the Fenton process(ALMA OXI Fenton) and UV oxidation(ALMA OXI UV) are an effective way of removing PFAS.

Incomplete oxidation can lead to the formation of so-called transformation products. A professional system design is therefore necessary to ensure complete oxidation of the PFAS.

Conclusion & recommendation for action

It can be assumed that PFAS will be included in Annex XVII of the REACH Regulation from 2025, which will lead to significant restrictions in terms of production, use and discharge. This will result in the introduction of requirements and limit values for the discharge of PFAS.

Proven technologies already exist for the successful removal of PFAS from wastewater and process water. Through our water treatment processes, we can help you remove PFAS from your wastewater or process water. Please contact us for more information or a free consultation.