The fourth treatment stage is an extension of conventional wastewater treatment that goes beyond mechanical (first stage), biological (second stage) and chemical-physical processes (third stage). It is used to eliminate trace substances and micropollutants such as pharmaceutical residues, hormones, pesticides, microplastics or other organic and inorganic compounds that conventional processes cannot completely remove from wastewater. This protects sensitive aquatic ecosystems and ensures better water quality.

Table of contents

Technological background of the fourth purification stage

The fourth treatment stage comprises highly developed technologies that are specifically designed to remove trace substances and micropollutants with low concentrations but a high environmental impact. These substances, such as pharmaceutical residues, hormones, pesticides, microplastics or industrial chemicals, find their way into wastewater and represent a serious burden for water bodies and ecosystems. The methods used combine physical, chemical and biological processes to achieve maximum purification performance.

1. activated carbon adsorption

Activated carbon adsorption is a proven technology for removing organic pollutants from wastewater. Activated carbon binds pollutants on its porous surface, effectively removing them from the water phase.

Technology:

- Powdered activated carbon (PAC):

Powdered activated carbon is dosed directly into the wastewater and then removed by filtration or sedimentation. This process is particularly suitable for variable loads, as the dosage can be flexibly adapted to the pollutant concentration. - Granulated activated carbon (GAC):

Granulated activated carbon is used in permanently installed adsorption filters. The wastewater flows through the activated carbon beds where the pollutants are adsorbed. GAC is suitable for continuous applications with stable loads.

Areas of application:

- Removal of organic pollutants such as pesticides, drug residues and hormones.

- Reduction of taste and odor-intensive compounds, especially in process water streams.

Advantages:

- Highly effective in binding many organic pollutants.

- Can be flexibly integrated into existing systems.

- Wide range of applications, from municipal wastewater treatment plants to industrial processes.

Disadvantages:

- Activated carbon requires regular regeneration or replacement, which incurs costs.

- If the water is heavily contaminated, the adsorption process can become inefficient as the capacity of the activated carbon is quickly exhausted.

Photo: Our ALMA FIL multi-layer filters with downstream ALMA FIL AK activated carbon filters

2. ozonation

Ozonation is a chemical oxidation process that uses ozone (O₃) as a strong oxidizing agent to break down organic pollutants. In the process, complex molecules are broken down into smaller, often more biodegradable compounds.

Technology:

- Ozone is generated from oxygen by electrical discharge and blown into the wastewater. There it reacts directly with pollutants or generates secondary oxidation products such as hydroxyl radicals, which have an even stronger oxidizing power.

- By-products such as bromates, which can be formed during the oxidation of bromide, must be minimized by suitable process controls.

Areas of application:

- Removal of organic micropollutants such as hormones, medicines, industrial chemicals and pesticides.

- Improving the degradability of substances that are difficult to biodegrade prior to biological post-treatment.

Advantages:

- Very high efficiency in the decomposition of organic pollutants.

- Fast reaction times and easy integration into existing wastewater treatment processes.

Disadvantages:

- High energy requirement for ozone production.

- Need for technical measures to control by-products such as bromate.

3. advanced oxidation processes (AOPs)

AOPs are among the most advanced oxidation processes and use the generation of hydroxyl radicals (OH-) to oxidize pollutants with high reactivity. These radicals decompose even stubborn organic compounds that are difficult or impossible to break down using other processes.

Technologies:

- Ozone and hydrogen peroxide (O₃/H₂O₂): The combination increases the formation of hydroxyl radicals, which increases oxidation efficiency.

- UV light with ozone or hydrogen peroxide (UV/H₂O₂): UV light accelerates the formation of hydroxyl radicals and enables the decomposition of complex molecules.

Areas of application:

- Degradation of persistent organic pollutants such as industrial chemicals, pesticides and pharmaceuticals.

- Improvement of biodegradability, especially in combination with downstream biological treatment processes.

Advantages:

- Broadly applicable for a wide range of pollutants.

- Effective even at very low concentrations of trace substances.

Disadvantages:

- High energy consumption and complex operation.

- Requires precise process monitoring and careful system planning.

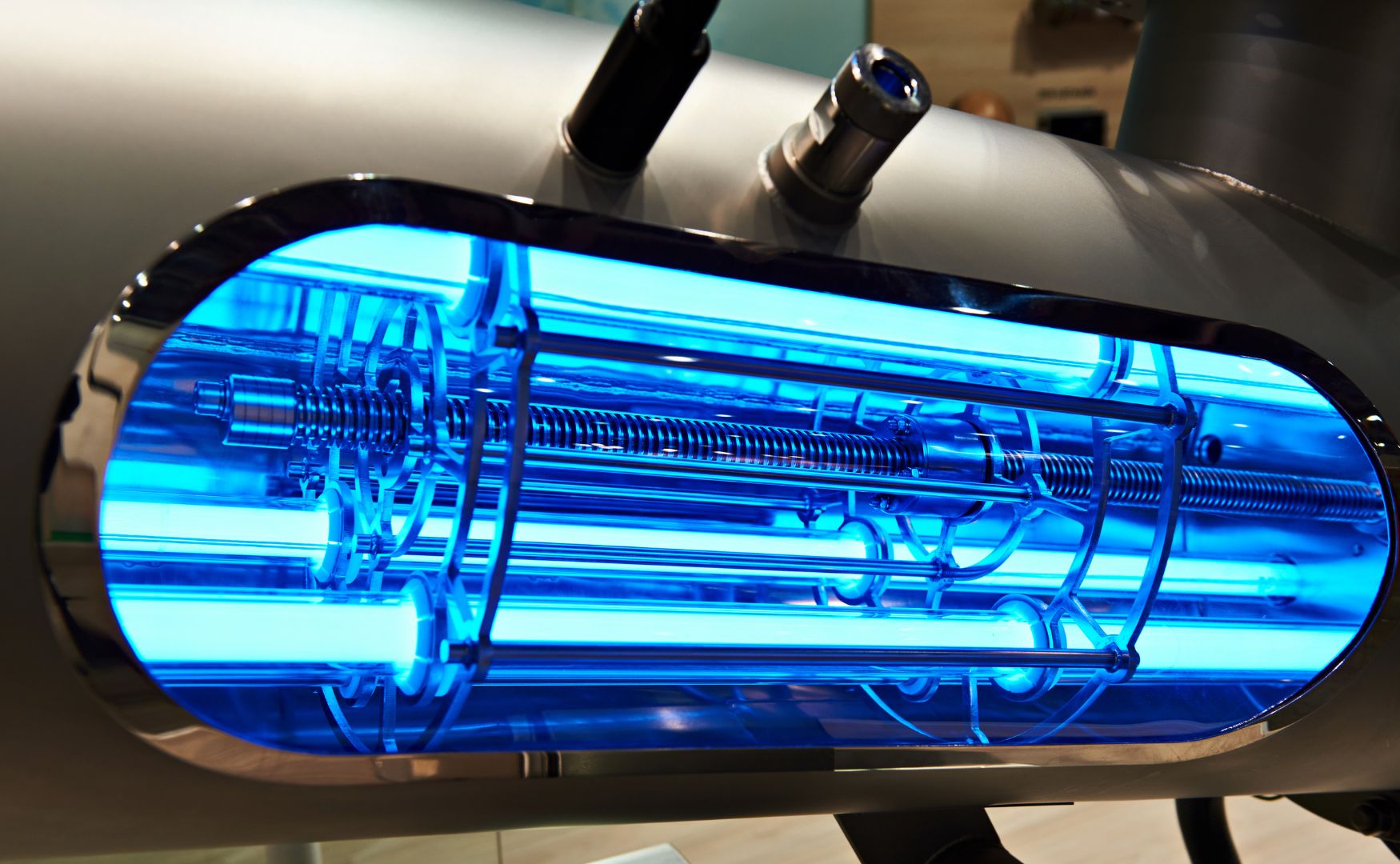

Photo: UV system in conjunction with the dosing of oxidizing agents such as hydrogen peroxide for the removal of trace substances(ALMA OXI UV)

4. membrane process

Membrane processes use physical barriers to remove pollutants from wastewater. Nanofiltration (NF) and reverse osmosis (RO) in particular play a key role in the fourth treatment stage.

Technology:

- Nanofiltration (NF):

Removes particles and molecules of medium size, including multivalent ions and organic compounds. - Reverse osmosis (RO):

Uses semi-permeable membranes to retain almost all dissolved substances, including salts, micropollutants and organic pollutants.

Areas of application:

- Production of high-purity water for industrial applications.

- Removal of organic pollutants, heavy metals and salts from wastewater.

Advantages:

- Very high retention rate for pollutants.

- Enables the recovery and reuse of water.

Disadvantages:

- High energy requirement due to the required pressure.

- Concentrate attack requiring additional treatment.

Photo: Our ALMA OSMO reverse osmosis system for removing trace and micro-pollutants

Areas of application for the fourth cleaning stage

The fourth purification stage is primarily used in industries and areas where pollution from trace substances is particularly high or where sensitive bodies of water need to be protected:

Industrial wastewater:

- Wastewater from the chemical, pharmaceutical and food industries often contains compounds that are difficult to break down and cannot be completely removed by conventional processes.

- Technologies such as reverse osmosis and activated carbon adsorption are used to ensure compliance with legal requirements.

Municipal wastewater treatment plants:

- In municipal wastewater treatment plants that treat wastewater containing pharmaceutical residues and microplastics, the fourth stage is an important step towards reducing environmental pollution.

Water reuse:

- Treatment of wastewater for reuse in industrial processes or for irrigation in water-scarce regions.

Future prospects

The introduction of the fourth purification stage is being driven by legal requirements and the increasing social focus on water protection. Future developments include

- Optimization of energy efficiency: Reduction of energy requirements for processes such as ozonation and AOPs.

- Integration into existing plants: Development of cost-efficient solutions for retrofitting existing wastewater treatment plants.

- Innovative materials: further development of membranes and adsorption materials for better binding of specific pollutants.

Conclusion

The fourth treatment stage represents a significant advance in wastewater treatment by responding to the increasing challenges posed by trace substances and micropollutants. Water quality is sustainably improved through the targeted use of advanced technologies such as activated carbon adsorption, ozonation, AOPs and membrane processes. This makes an important contribution to protecting the environment and safeguarding high-quality water resources for future generations.

For further information on our products, please feel free to contact us at any time!