The demand for sustainable construction solutions in the industry is constantly increasing. In times of climate change and resource scarcity, it is crucial not only to rely on efficient technologies, but also to reduce the carbon footprint of the construction method itself. Modular construction with the ALMA module is a promising solution for water treatment plants and wastewater treatment plants. As a specialist company in plant construction, we would like to highlight the main advantages of this construction method compared to conventional hall construction - particularly in terms of land consumption, concrete use, sealing and savings on steel and CO₂ emissions.

Table of contents

The comparison: ALMA module vs. conventional hall construction

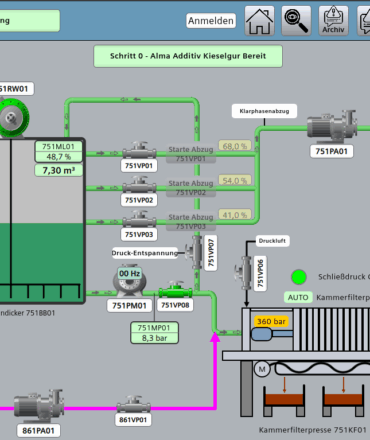

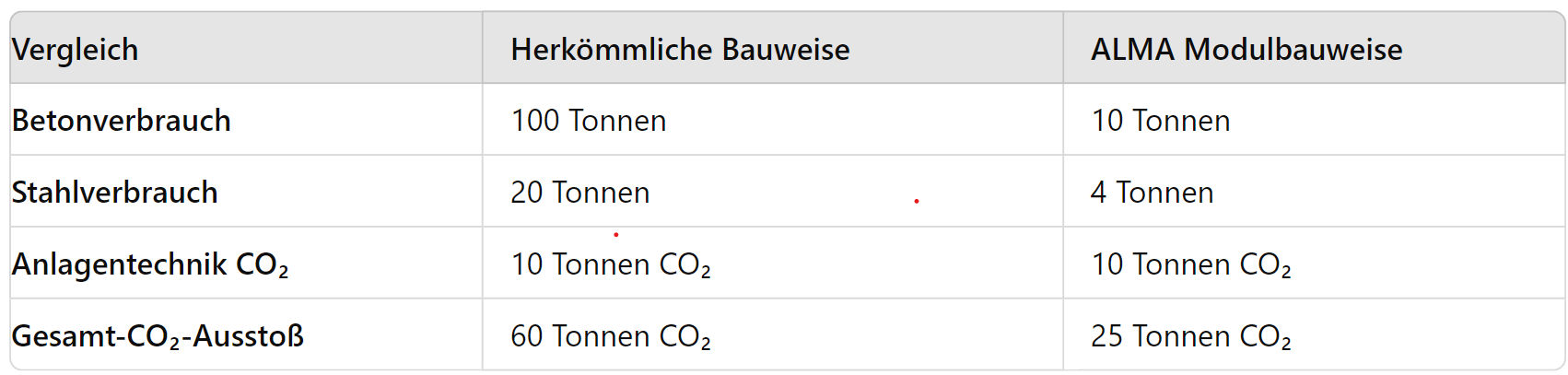

A typical modular system with dimensions of 3×12 meters provides a classic example of the comparison between a conventional hall construction method and the ALMA module. In the following analysis, we look at savings in concrete consumption, the use of steel and the CO₂ emissions generated by the construction of the system itself.

Savings in concrete consumption and the carbon footprint

In conventional hall construction, a large amount of concrete is required to build the basic structure. This leads to a considerable burden on the environment, as the production of concrete is not only very energy-intensive, but also releases large amounts of CO₂. CO₂ emissions in concrete production are mainly caused by the chemical reaction in the production of cement, the binding agent of concrete.

A modular system of 2×12 meters in conventional construction would require approx. 80 - 100 tons of reinforced concrete. This leads to CO₂ emissions of around 25 tons.

However, concrete consumption can be drastically reduced by using the ALMA modular construction method. The use of modular foundations and specially optimized foundation strips ensures that up to 90 - 95 tonnes of reinforced concrete - and therefore 25 tonnes of CO₂ - are saved. This is a significant contribution to reducing the ecological footprint, especially in large-scale industrial projects.

Reduction in the use of steel

The use of steel results in a further significant savings effect. Traditional hall structures usually rely on an extensive steel construction, which serves to support the roof and stabilize the facility. However, steel production is also one of the most CO₂-intensive industries in the world. Depending on local requirements and the design of a conventional plant, around 20 tons of steel are used, which is associated with 15 tons of CO₂ emissions.

The ALMA modular design makes it possible to dispense with a large proportion of this steel, as the modules are self-supporting and designed in such a way that they do not require extensive steel girders. This leads to a significant saving of 20 tons of steel and reduces CO₂ emissions by 15 tons.

Photo: Permeate-staged reverse osmosis system with ultrafiltration in the ALMA module

CO₂ emissions from the system technology

Of course, the system technology itself, i.e. the installed pumps, pipes, valves and other components, also contributes to the CO₂ balance. In a conventional system, the technology would generate around 10 tons of CO₂.

Thanks to the modular prefabrication of the technical components in the ALMA module, a more efficient construction method can also be guaranteed here. As the modules are prefabricated in the factory and only assembled on site, not only is the construction time reduced, but also the carbon footprint caused by transportation and assembly work.

Overall balance and savings

If you add up the savings mentioned, a clear picture emerges. Conventional system technology in a standard hall construction would have a total CO₂ footprint of 60 tons of CO₂. In contrast, the ALMA module, including the foundation strips, only generates 25 tons of CO₂. This means a CO₂ reduction of more than 50% - an impressive result that clearly shows how much potential there is in modular construction.

Table: Comparison between the standard hall construction method and the ALMA modular construction method

Conclusion: ALMA modular construction as a solution for sustainable industrial buildings

The ALMA modular construction method offers a number of advantages that go far beyond CO₂ savings. In addition to the significant reduction in land consumption and the use of building materials, it also offers flexibility in planning, shorter construction times and lower operating costs. For companies looking for sustainable, future-proof solutions for their production facilities, the ALMA module is an extremely attractive alternative to conventional hall construction.

Particularly against the backdrop of stricter environmental regulations and increased awareness of climate protection, modular construction offers a decisive advantage - it combines technological efficiency with ecological responsibility. With ALMA modular construction, companies can not only optimize their operational processes, but also make an active contribution to environmental protection.

For further information and individual advice on our ALMA module, please do not hesitate to contact us. Simply contact us!