The anaerobic wastewater treatment is a biological process in which microorganisms break down organic compounds in an oxygen-free environment. Unlike in aerobic processes, where oxygen is required as an electron acceptor, the microorganisms in the anaerobic process use other compounds such as carbon dioxide, sulphate or nitrate.

At the heart of this process is the microbial community:

Hydrolysis bacteria break down complex organic molecules (fats, proteins, carbohydrates) into smaller components.

Acid formers convert these into organic acids, alcohols and hydrogen.

Methane formers (archaea) ultimately produce methane (CH₄) and carbon dioxide (CO₂) from these intermediate products - together known as biogas.

Table of contents

Advantages of anaerobic treatment

Energy recovery instead of energy consumption - the resulting biogas can be used to generate electricity and heat.

High COD and BOD5 degradation performance with comparatively low sludge production.

Lower nutrient requirement (nitrogen, phosphorus) compared to aerobic processes.

Compact system size for high organic loads.

Functional principle of an anaerobic reactor

The organic-rich wastewater is fed into a closed, gas-tight reactor. The biomass (sludge or granulate) contained there ensures biological decomposition. The resulting biogas is collected in the upper part of the reactor, purified and used to generate energy. The biomass is kept in the system via various internal or external separation stages (biomass recirculation), while the treated water is discharged.

The system technology can vary depending on the composition of the wastewater, solids content, temperature, hydraulic load and COD concentration. ALMAWATECH uses three proven basic concepts for this:

In the following, we present these three processes, their advantages and areas of application as well as the differences in handling dissolved and undissolved organic substances.

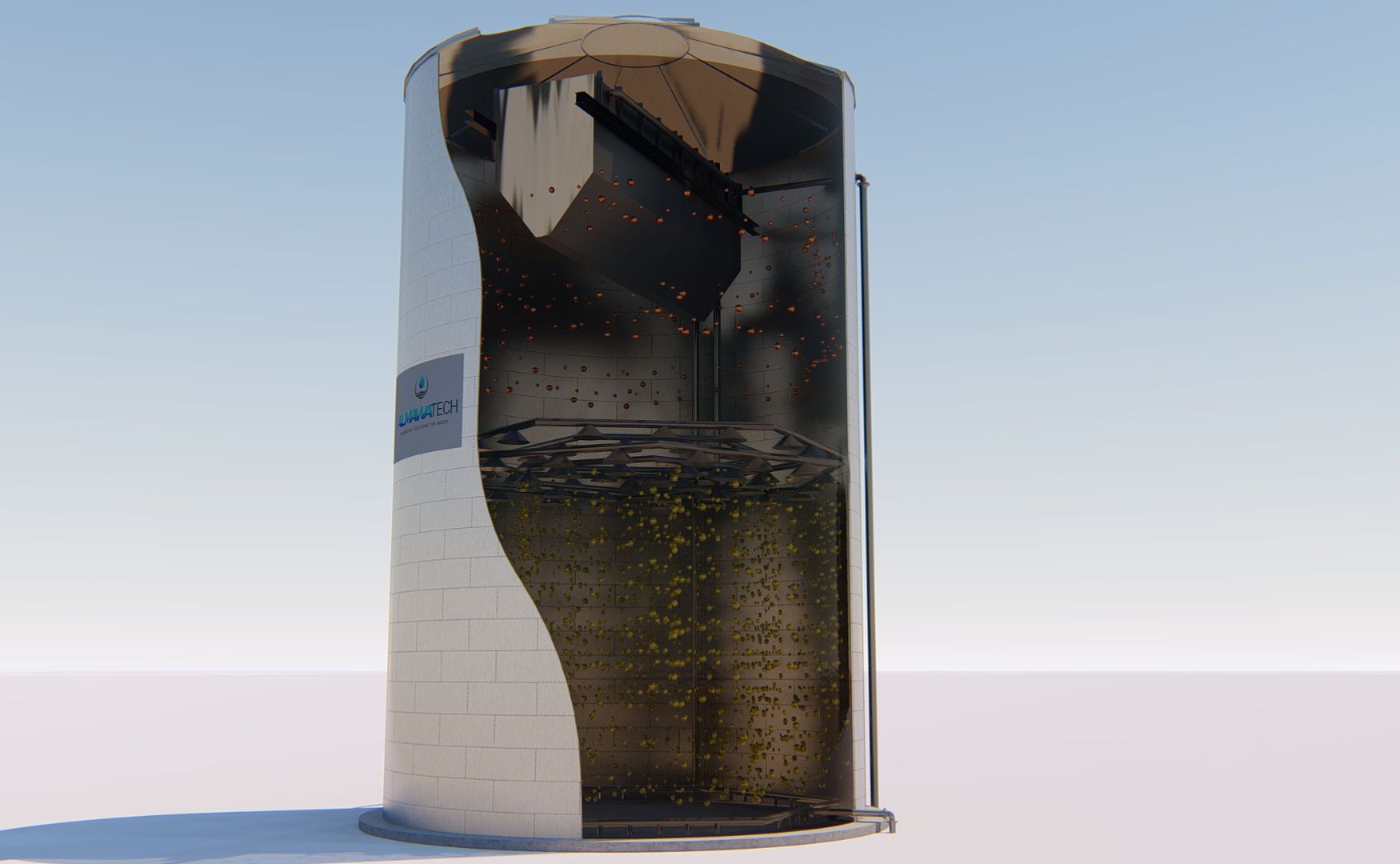

Photo: Our ALMA BHU GMR biogas plant as a fully mixed reactor with external biomass recirculation

Fully mixed reactors with biomass recirculation

Fully mixed anaerobic reactors are robust and proven systems that are particularly suitable for wastewater with a high proportion of undissolved or poorly degradable organic substances. In a closed, gas-tight tank, the wastewater is intensively mixed with the existing biomass so that there is uniform contact between the substrate and microorganisms. Mixing can take place in two ways:

Mechanical agitators - ensure an even distribution of solids and nutrients throughout the reactor volume.

Biogas plants such as the ALMA BHU GMR reactor - use the biogas produced in the process for mixing. This is significantly more energy-efficient, especially with large volumes, and prevents typical problems of mechanical systems, such as calcium deposits on agitators, which can lead to imbalance, mechanical damage and, in the worst case, reactor and agitator failure.

Advantages of fully mixed systems

High tolerance to high solids content in the inlet

Processing of a wide variety of organic substances (dissolved, suspended, particulate)

High process stability with fluctuating feed volumes and loads

Flexible operation with changing wastewater compositions

High biogas yield due to complete substrate contact with the biomass

Energy-efficient operation with gas mixing (especially for large-volume systems)

No moving mixing elements in the medium in gas mixing systems → Less maintenance required

Areas of application

Food industry (dairies, slaughterhouses, fat and oil processing)

Beverage industry (fruit juice, brewery, soft drinks)

Chemical industry with particulate residues

Municipal wastewater treatment technology - the fully mixed reactor (especially as a digester) is the most frequently used technology for anaerobic treatment.

Optimum material flow separation for greater efficiency

A particularly effective approach is to separate the dissolved and undissolved organic components prior to anaerobic treatment - for example by means of upstream flotation.

The dissolved substances can then be processed in high-performance reactors such as UASB or EGSB plants, which achieve optimum degradation rates for such substrates.

The undissolved solids are treated in digesters or fully mixed reactors, where longer retention times and complete mixing are guaranteed.

This separation significantly reduces the treatment energy required, increases the biogas yield and leads to more efficient biogas plants overall - both on an industrial and municipal scale.

Photo: Our ALMA BHU GMR biogas plant as a fully mixed reactor with external biomass recirculation

UASB reactors (Upflow Anaerobic Sludge Blanket)

The UASB reactor is one of the world's most widely used processes for the anaerobic treatment of industrial wastewater with a high proportion of dissolved organic matter. It was developed in the 1970s and is characterized by its compact design and very high biomass content.

Functional principle

Inlet from below: The wastewater is introduced at the bottom of the reactor and flows from the bottom upwards through the sludge blanket.

Granulated biomass: The biomass in the reactor is in the form of dense, easily sedimentable granules. These consist of highly active anaerobic microorganisms.

Contact & degradation: While the water rises through the granulate bed, the organic substances are degraded in several stages (hydrolysis, acid formation, methane formation).

Biogas formation: The resulting methane-CO₂ mixture rises to the top and at the same time ensures gentle internal mixing.

Three-phase separation: At the upper end of the reactor there is a so-called gas-solids-liquid separator (GSL ), which separates water, gas and biomass from each other:

The biogas is discharged upwards and used to generate energy.

The biomass sinks back into the reactor.

The purified water is discharged from the overflow.

Advantages of the UASB system

High space-time yield due to high biomass concentration (10-30 g VSS/l)

Very compact design → low space requirement

Low energy consumption - no external agitators required as the biogas provides the mixing

Simple hydraulics with only one main direction of water flow

Good process stability with fluctuating feed concentrations (COD)

Short hydraulic dwell times (6-12 hours possible) with high extraction rates

Robust against shock loads in terms of volume flow and COD concentration

Areas of application

UASB reactors are particularly suitable for liquid, largely particle-free wastewater with high biodegradability:

Food and beverage industry (breweries, soft drinks, fruit juices)

Sugar and starch factories

Chemical industry (easily degradable organic chemicals, e.g. ethanol, organic acids)

Paper and pulp industry (after pre-treatment to remove coarse solids)

Limits and pre-treatment

Sensitivity to solids: High levels of undissolved solids can disrupt the sludge structure → Pre-treatment such as sedimentation or flotation is often required.

Grease and oil load: High concentrations of grease can lead to the formation of floating ceilings → grease separator may be necessary.

Temperature dependence: Optimum operation usually at 30-38 °C (mesophilic), heating for cold inlets if necessary.

Photo: Our UASB reactor ALMA BIO UASB with internal 3-phase separator

EGSB reactors (Expanded Granular Sludge Bed)

The EGSB reactor (Expanded Granular Sludge Bed) is a further development of the UASB concept and is one of the most efficient anaerobic reactor systems for liquid, dissolved wastewater streams. The decisive difference lies in the higher hydraulic flow velocity, which slightly raises and expands the granular bed during operation. This intensifies the contact between biomass and wastewater and significantly increases the mass transfer rate.

Functional principle

Inlet from below: As with the UASB, the wastewater enters at the bottom of the reactor.

Increased flow velocity: The sludge granulate bed expands due to higher feed velocities and, if necessary, internal recirculation.

Better flow: The upward movement increases the contact surface between biomass and substrate, which leads to a very high degradation performance even with a low organic load.

Three-phase separation: At the head of the reactor, an optimized gas-solids-liquid separator separates the biogas produced, the biomass and the purified water.

Biomass recirculation: Biomass is efficiently retained in the system, fine particles are captured and returned to the reactor.

Advantages of the EGSB system

Very high volumetric degradation performance (up to 15-20 kg COD/m³-d)

Compact design with minimal space requirements

Short hydraulic dwell times (3-8 hours) possible

Effizient auch bei niedrigen Zulauf-CBS-Werten (< 3.000 mg/l) – im Gegensatz zu klassischen UASB-Systemen

High biomass concentration due to stable granulate structure

Very low sludge production → low disposal costs

Low energy consumption (only for recirculation pumps)

Areas of application

EGSB reactors are ideal for low to medium-high polluted wastewater containing mainly dissolved and easily degradable organic substances:

Beverage industry (soft drinks, fruit juices, breweries)

Sugar, starch and confectionery production

Fermentation industry (e.g. ethanol, organic acids)

Food industry with easily filterable wastewater

Partial flows from the chemical industry with a defined composition

Limits and pre-treatment

Sensitivity to solids: High levels of undissolved substances can disrupt the expansion of the bed → Pre-treatment by sedimentation, filtration or flotation required.

Grease and oil load: If the proportion of lipophilic substances is too high, there is a risk of granulate sticking → Grease separator or chemical-physical pre-treatment recommended.

Hydraulic requirements: Require constant flow velocities and stable inflow conditions for optimum expansion.

Temperature control: As with the UASB, mesophilic conditions (30-38 °C) are optimal; heating may be necessary.

Photo: Drawing of our EGSB reactor ALMA BHU EGSB, in which the two-stage structure and the 3-phase separator arranged at the top are clearly recognizable.

Dissolved vs. undissolved substances in fermentation

The choice of a suitable anaerobic reactor type depends largely on whether the wastewater contains mainly dissolved or undissolved organic substances:

Dissolved organic substances (e.g. sugars, alcohols, organic acids) are degraded very efficiently by UASB and EGSB reactors, as they diffuse easily into the biomass and are quickly converted.

Undissolved organic substances (e.g. fats, proteins, fibers) require longer contact times and more intensive mixing, which is guaranteed in fully mixed reactors with biomass recirculation.

Mixed wastewater with both dissolved and undissolved components often benefits from a combination of mechanical/physical pre-treatment (e.g. flotation) and subsequent anaerobic treatment.

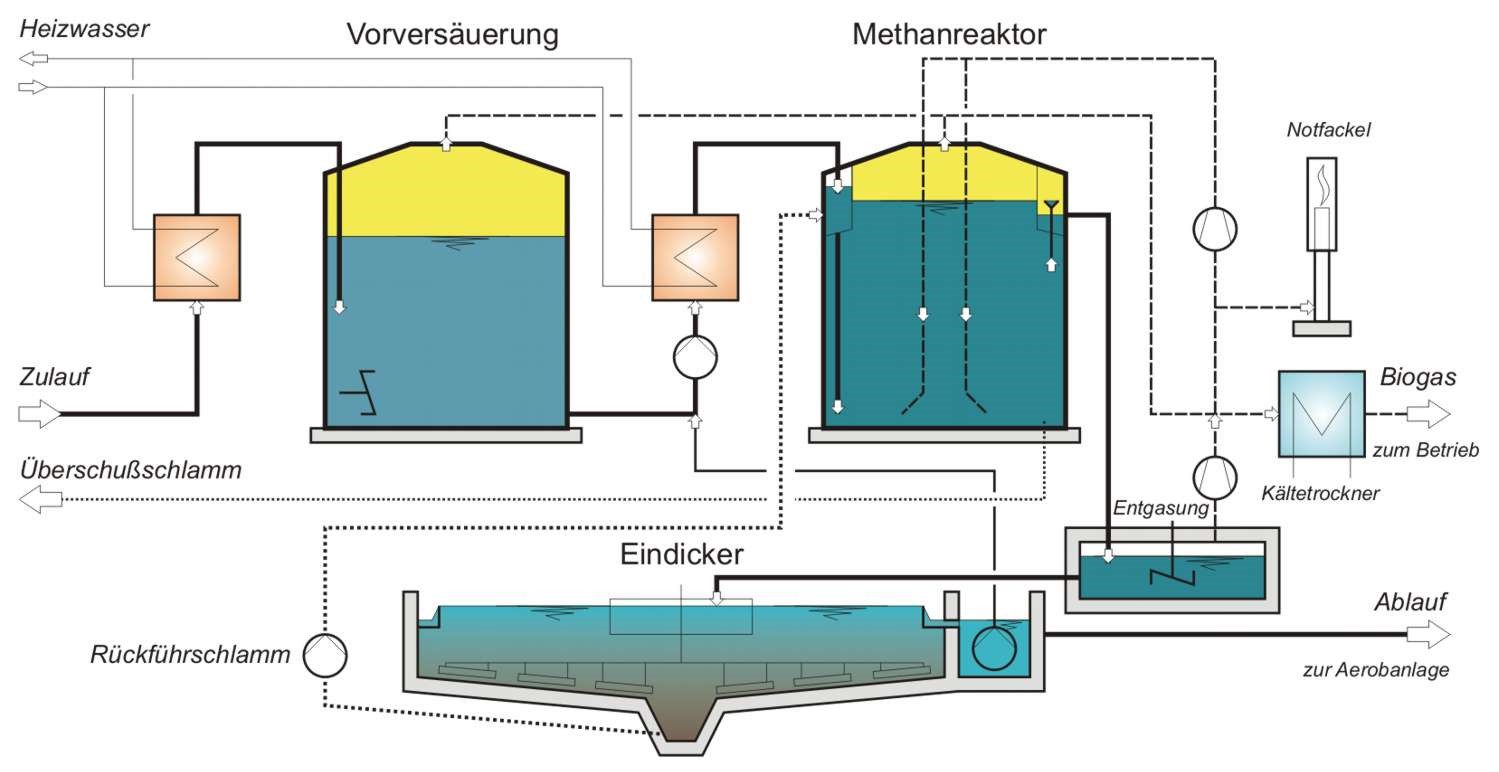

Photo: Process diagram of a fully mixed ALMA BHU GMR biogas reactor, with prior acidification and external biomass recirculation

Conclusion - The right solution for every wastewater challenge

With the fully mixed biogas reactors with biomass recirculation, the compact UASB reactors and the high-performance EGSB reactors, we cover the entire range of modern anaerobic processes. Thanks to our many years of experience in the design and combination of these technologies, we can offer tailor-made solutions for almost any industrial wastewater problem - including optimum pre- and post-treatment.