Reverse osmosis (RO) systems are now standard in industrial water treatment. Whether in the food and beverage industry, in pharmaceutical and chemical production or in power plants - membranes play a central role wherever high-purity water is required.

However, for a reverse osmosis system to work reliably, it is dependent on a consistently high raw water quality. If there is insufficient pre-treatment, deposits, fouling or mechanical damage can drastically shorten the service life of the membranes. A current project at a river water treatment plant has clearly demonstrated this.

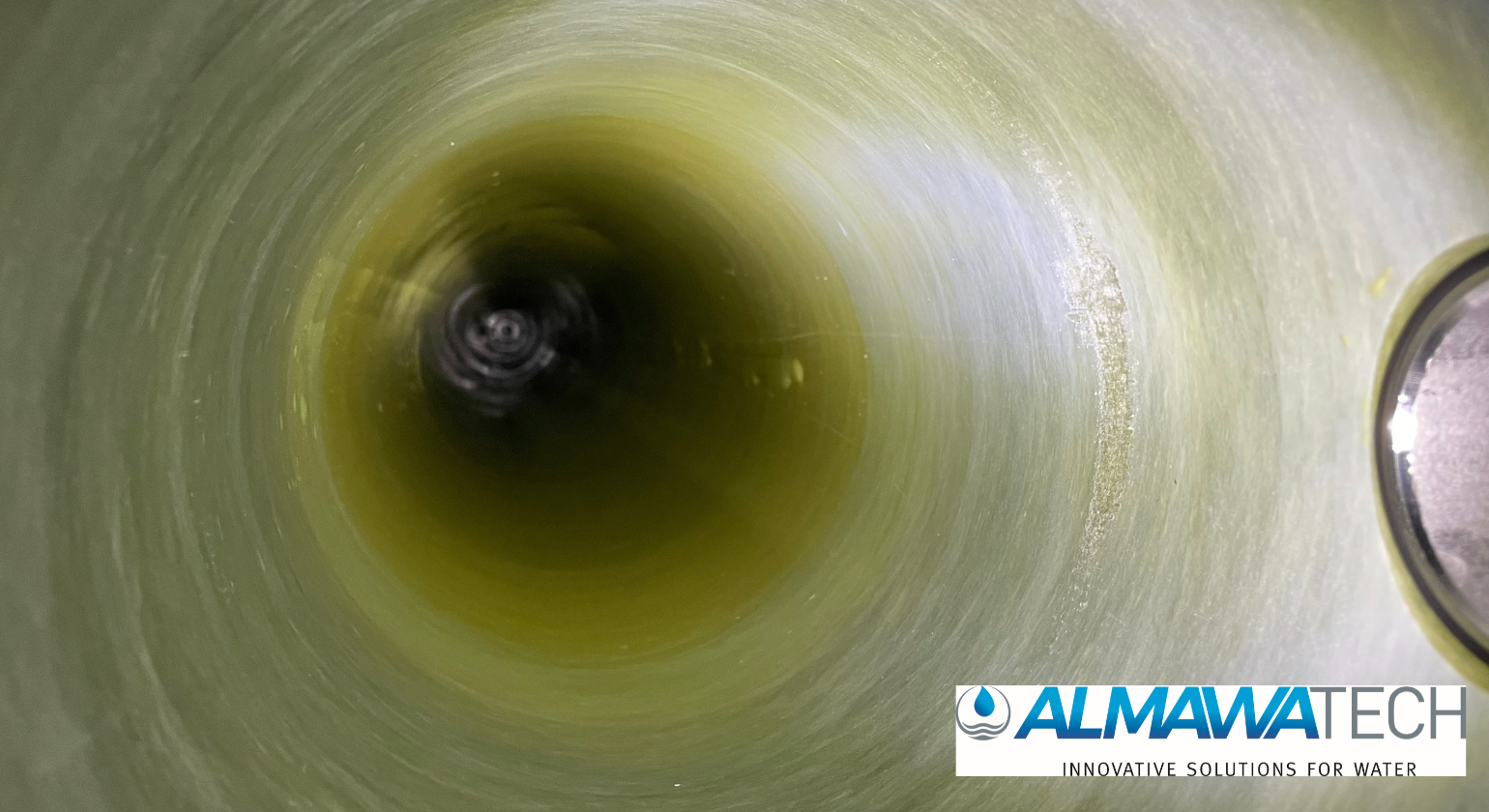

Photo: There are clear deposits of sand and gravel on the reverse osmosis membranes, which have led to irreversible damage.

Table of contents

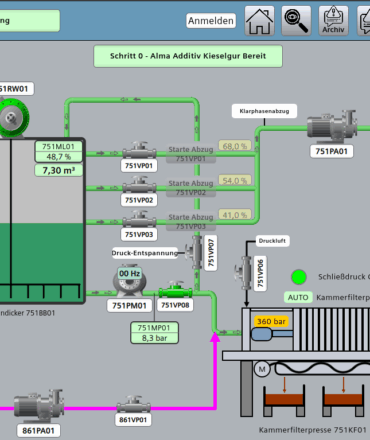

The specific case: Membrane replacement after particle damage

A diaphragm had to be replaced in a third-party system that we manage. A clear picture emerged as soon as the system was removed:

Sand and gravel particles had been deposited on the membranes.

These foreign substances led to mechanical abrasion on the membrane surface.

The pressure pipes were also visibly damaged.

Such damage does not occur overnight. They are an indication that the upstream pre-treatment did not sufficiently remove particles from the raw water. As a result, the sensitive reverse osmosis membranes had to be replaced far earlier than planned.

Photo: Visual inspection of the pressure pipes for damage and signs of wear.

Why pre-treatment is so important

A reverse osmosis membrane acts like a very fine sieve - it separates dissolved salts, organic substances and microorganisms from the water. However, it is not designed to retain coarse particles or sand. These must be reliably removed before entering the membrane.

Typical pre-treatment steps are

Sedimentation or lamella separator to separate coarse solids.

Sand and gravel filtersthat retain particles and suspended matter.

Micro- or ultrafiltrationto eliminate the finest turbidity and bacteria.

Precipitation and flocculation to destabilize colloidal substances and make them separable.

Biofiltration or activated carbon to reduce residual organic matter and odors/tastes.

If such protection is missing, particles reach the membrane and cause damage that is not only cost-intensive, but also jeopardizes the operational safety of the entire system.

Consequences of inadequate pre-treatment

The consequences are far-reaching:

Premature membrane replacement - membranes that could actually last 5-7 years have to be replaced after 1-2 years.

Higher energy consumption - dirty membranes increase the differential pressure, pumps have to work harder.

Consequential damage - not only the diaphragms, but also pressure pipes, pumps and valves can be damaged.

Production risks - Failures or restricted water quality can jeopardize the operation of entire production lines.

Rising operating costs - spare parts, energy and unproductive downtimes add up.

Photo: Photo of the membrane replacement on the external system.

Economic consideration: membrane exchange vs. pre-treatment

A membrane set for an industrial system can quickly cost tens of thousands of euros. Added to this are labor costs for replacement and downtime.

On the other hand, the investment and operating costs for optimized pre-treatment are significantly lower in the long term. Even additional stages such as ultrafiltration or a chemical-physical precipitation and flocculation stage often pay for themselves after just a few years - simply through the savings in membrane costs and the higher operational reliability.

Our approach: eliminate causes, not just treat symptoms

At ALMAWATECH, we do not view membrane replacement in isolation. We always look at the cause of the damage. This includes

Analysis of the membrane surfaces (deposits, fouling types).

Inspection of the pre-treatment plant (filtration, precipitants, operational management).

Water analyses (turbidity, COD, TOC, iron/manganese, suspended solids, particle sizes).

On this basis, we develop solutions together with our customers to ensure that the new membranes are permanently protected. Because replacing a membrane is only half the solution - only the right pre-treatment makes operation economical and sustainable.

Conclusion: protection instead of repair

The case in the river water treatment plant shows that sand and gravel in the raw water can cause massive damage to a reverse osmosis system in a very short time. Replacing membranes is then only a short-term emergency measure.

In the long term, robust and coordinated pre-treatment that reliably treats the raw water and protects the sensitive membranes is crucial.

If you want to ensure that your reverse osmosis system works reliably, achieves a long service life and can be operated economically, we will be happy to support you - from membrane replacement to optimization of pre-treatment.