Disinfection is a critical process in industrial water treatment to eliminate or control the growth of microorganisms such as bacteria, viruses, algae and fungi. This step is particularly important to ensure hygienic standards, ensure the safety of drinking and process water and prevent the spread of waterborne pathogens.

Table of contents

Technical background to disinfection

The disinfection process aims to render pathogenic organisms harmless or kill them so that the water can be used safely for its intended purpose - whether in industry, food production or in the cooling circuit. The efficiency of disinfection depends on various factors, including the type and concentration of the disinfectant, the exposure time and the nature of the water (pH value, organic load).

Disinfection methods

There are several methods for disinfecting water, each of which has its own advantages and disadvantages. The most common methods include

1. UV disinfection

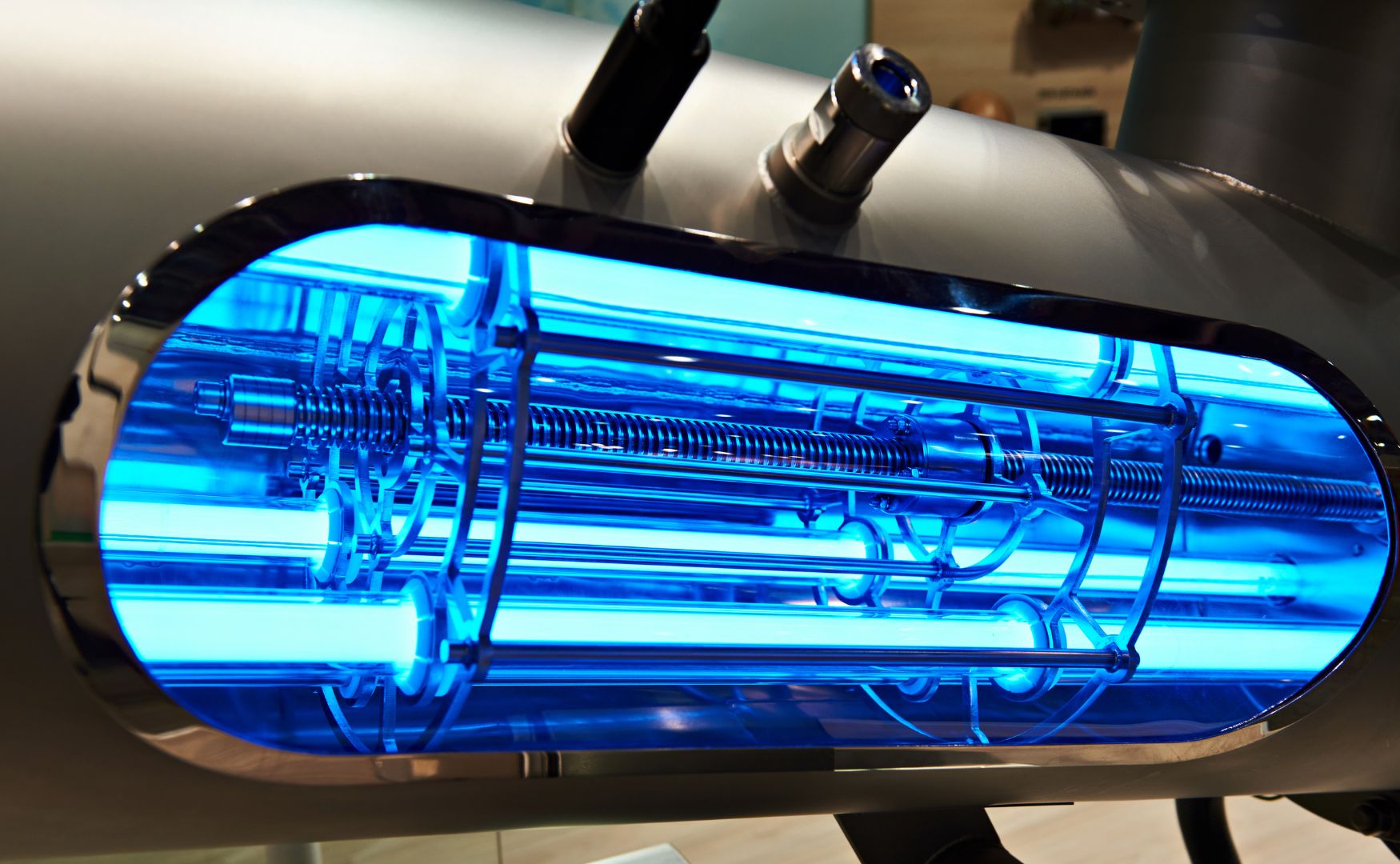

UV disinfection uses ultraviolet radiation to render microorganisms inactive. The radiation destroys the organisms' DNA so that they can no longer reproduce. UV systems such as our ALMA OXI UV offer the advantage that they work without the use of chemical agents and leave no by-products in the water. They are particularly suitable for the disinfection of drinking water and process water in the food and pharmaceutical industries as well as in cooling water treatment.

Photo: UV disinfection ALMA OXI UV

2. chlorine dosing

Chlorine is one of the most widely used disinfectants. It is particularly effective against a large number of microorganisms and leaves a residual effect that prevents subsequent contamination. Chlorine is often used in industrial water circuits to ensure long-term water quality. The challenge with chlorine dosing is to ensure the correct dosage, as an excessively high chlorine content can produce harmful by-products such as trihalomethanes (THM).

3. ozonation

Ozone is a strong oxidizing agent and can be used in water treatment for disinfection and to remove organic compounds and odours. Compared to chlorine, ozone works faster and leaves no harmful residues. However, ozone has no residual effect, which means that subsequent germ formation is not prevented. Ozone is often used in drinking water treatment and in process water treatment, especially where high hygiene standards are required.

4. hydrogen peroxide

Hydrogen peroxide (H₂O₂) is used as a powerful oxidizing and disinfecting agent. It is particularly suitable in combination with other disinfection methods, such as UV light, to achieve an increased disinfection effect. In industrial water treatment, hydrogen peroxide is often used to combat biofilms in cooling water circuits or in combination with Fenton reactions to remove poorly degradable organic compounds.

Photo: Dosing station for hydrogen peroxide installed in the ALMA module

Conclusion

The choice of the right disinfection method depends heavily on the requirements of the water cycle, the water parameters and the economic aspects. With the combination of our ALMA OXI UVsystems and the precise dosing of chlorine, ozone and hydrogen peroxide, we offer you tailor-made solutions to ensure reliable disinfection and optimize operating costs at the same time.