Chemical-physical treatment is a method of purifying industrial wastewater and process water that combines chemical and physical processes to remove pollutants from the water or render them harmless. This treatment approach is often used in industries that produce wastewater containing persistent, toxic or dissolved compounds that cannot be effectively treated by biological processes alone.

Table of contents

Technical background

Chemical-physical treatment is based on a series of process steps in which the targeted use of chemicals and physical separation processes such as filtrationsedimentation and flotation pollutants are separated from the wastewater. The choice of process depends on the type and composition of the wastewater, in particular the heavy metals, organic pollutants and nutrients such as phosphates it contains.

Chemical-physical treatment is a step-by-step process in which several methods are combined to achieve maximum cleaning efficiency. Typical steps include:

1. neutralization and pH adjustment

As a rule, treatment begins with pH control, as many chemical precipitation and flocculation processes have to take place within a certain pH range. By adding acids or bases (such as sulphuric acid or caustic soda), the pH value of the wastewater is adjusted so that the subsequent treatment steps run optimally.

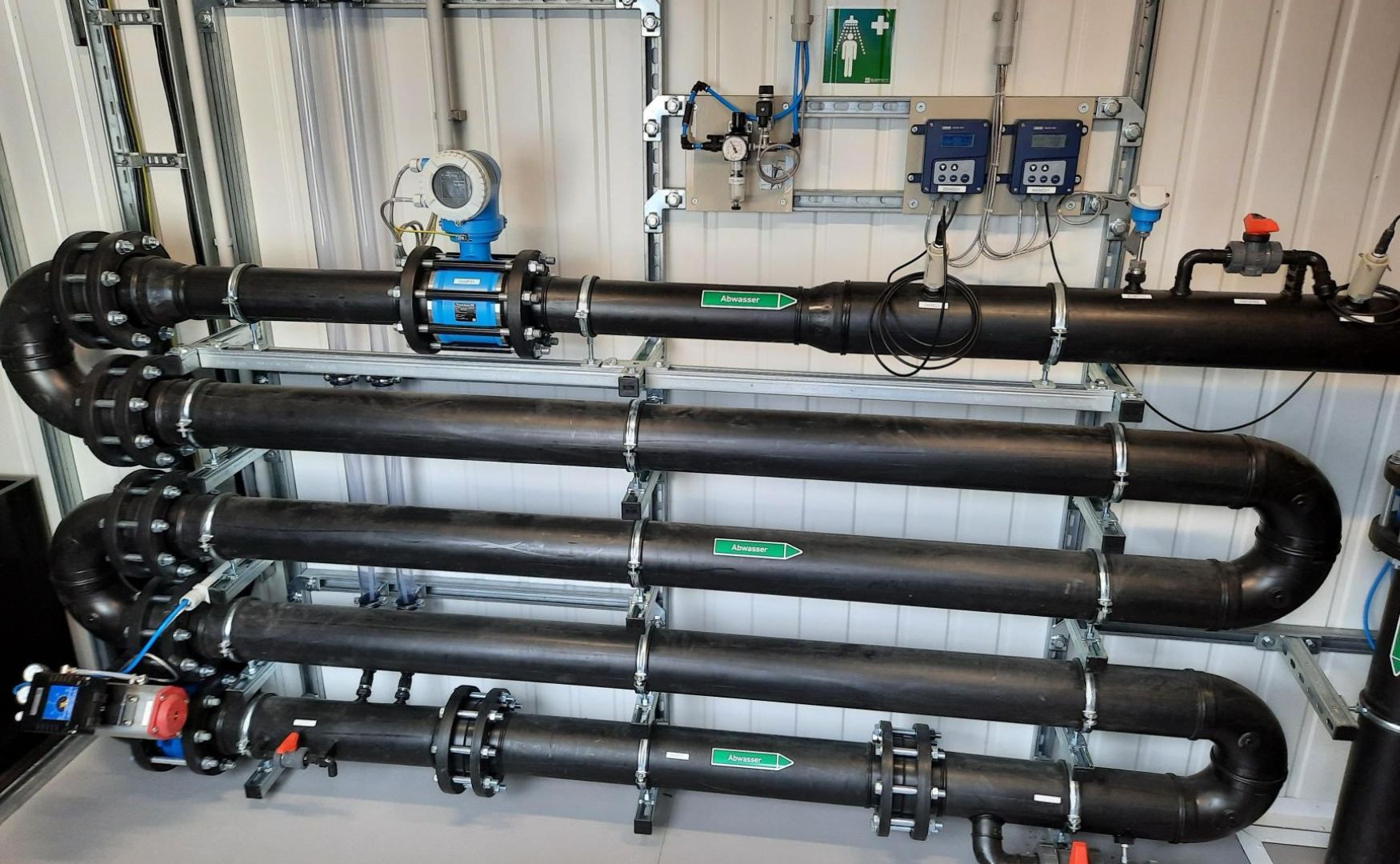

Photo: Reaction loop of the ALMA Neutra automatic neutralization system

2. felling

Chemical precipitation is a core process of chemical-physical treatment. Here, chemicals such as precipitants (e.g. iron or aluminum salts) are introduced into the wastewater in order to convert dissolved impurities, in particular heavy metals or phosphates, into an insoluble form. These then form solid particles that can be removed by subsequent separation processes such as sedimentation or filtration.

3. flocculation

Precipitation is often followed by flocculation, in which flocculants (such as polyelectrolytes) are added to agglomerate the precipitation products into larger flocs. These flocs are easier to separate and ensure improved solid-liquid separation.

Photo: CP system ALMA CHEM MCW for the elimination of heavy metals, AOX, hydrocarbons and cyanides

4. sedimentation

The flocs sink in a sedimentation tank due to gravity and form the so-called sludge, which is separated from the purified liquid. The resulting sludge can then be dewatered and disposed of.

5. flotation

Another physical separation process that is often used in combination with chemical processes is flotation. Here, fine air bubbles are introduced into the wastewater, which adhere to the flocs and transport them to the surface, where they are skimmed off as sludge.

Photo: ALMA NeoDAF flotation plant

6. filtration

After precipitation and flocculation, filtration processes such as sand filters or activated carbon filters can be used to remove any remaining fine particles, undissolved substances or organic residues.

Photo: ALMA BHU SMF filtration system for large water flows

7. oxidation and reduction

In some cases, oxidizing agents such as hydrogen peroxide, ozone or chlorine are also used to oxidize organic pollutants and heavy metals. Reducing agents such as sodium bisulphite are used to convert heavy metals that are difficult to dissolve into a soluble form, which can then be removed by other processes.

Areas of application for chemical-physical treatment

Chemical-physical treatment is used in a variety of industries that produce wastewater containing problematic substances, such as:

Electroplating and metal finishing

This produces wastewater that often contains high concentrations of heavy metals (such as zinc, copper, nickel and chromium). These metals are removed from the wastewater by chemical precipitation and subsequent flocculation before it is treated further or discharged.Food and beverage industry

Food processing often produces wastewater with a high content of organic substances as well as fats and oils, which must be separated using chemical processes such as precipitation or flotation in order to reduce the organic load.Pharmaceutical and chemical industry

In the chemical and pharmaceutical industry, chemical-physical treatment is used to remove toxic chemicals, organic solvents and heavy metals from process wastewater. Special oxidation processes are often required to break down certain compounds.Surface treatment and paint stores

Wastewater with a high concentration of organic compounds and heavy metals is produced in businesses that use paints, varnishes or surface coatings. These must be removed by precipitation, flocculation and subsequent filtration.Electronics and microelectronics industry

In semiconductor manufacturing and microelectronics, high-purity chemicals are used in production that leave toxic residues in wastewater after use. Chemical-physical processes are used to neutralize these pollutants and remove heavy metals.

ALMAWATECH Chemical-Physical Plants: ALMA CHEM MCW

A specific application of chemical-physical treatment in practice is the ALMA CHEM MCW plantfrom ALMAWATECH, which specializes in the pre-treatment and purification of industrial wastewater. The ALMA CHEM MCW plants combine several chemical-physical processes to efficiently remove heavy metals, organic compounds and nutrients. This system is particularly flexible and can be adapted to different types of wastewater.

The features of the ALMA CHEM MCW-system include:

- Precipitation and flocculation processes for the removal of heavy metals and phosphates.

- Neutralization and pH correction to adjust the wastewater composition.

- Post-treatments such as multi-layer filters or ion exchangers to achieve high-purity water for reuse or discharge.

Advantages of chemical-physical treatment

High efficiency in the removal of heavy metals: Chemical-physical treatment is particularly effective in removing heavy metals and other problematic contaminants that are difficult to biodegrade.

Flexibility: The combination of chemical and physical processes makes this treatment flexible, as it can be adapted to different types of wastewater and loads.

High purification performance: The combination of precipitation, flocculation and filtration means that even fine particles and dissolved pollutants can be removed from the water, resulting in a high purification quality.

Compliance with legal limits: By using these processes, companies can ensure that they comply with the legally prescribed discharge limits and thus avoid penalties and environmental pollution.

Photo: CP system ALMA BHU LHPS with high-performance lamella separator

Challenges of chemical-physical treatment

Sludge formation: The chemical reactions lead to the formation of precipitated sludge, which must be treated, dewatered and disposed of as residual material. This increases operating costs.

Chemical consumption: Chemical treatment requires the use of precipitants, neutralizing agents and other chemicals, the cost and environmental impact of which must be taken into account.

Control complexity: Precise control of pH value, chemical addition and process parameters requires precise automation and monitoring of the system in order to achieve optimum cleaning performance.

Conclusion

The chemical-physical treatment is a central component of industrial wastewater treatment, especially in industries where biological processes are not sufficient to achieve the required water quality. With the combination of chemical precipitation processes, flocculation and physical separation processes, pollutants can be efficiently removed from the water. Systems such as the ALMA CHEM MCW from ALMAWATECH offer a flexible and reliable solution for various types of wastewater and help companies to meet their environmental requirements and ensure water quality.

For further information on our products, please feel free to contact us at any time!