Caustic soda, also known as sodium hydroxide solution (NaOH), is one of the most important bases in the chemical industry and is widely used in industrial water and wastewater technology. Due to its strong alkaline properties, caustic soda is used for pH control, neutralization, regeneration of ion exchangers and in cleaning processes. At the same time, handling caustic soda requires a high degree of technical understanding and safety precautions.

This article explains in detail the chemical properties, applications and challenges involved in handling caustic soda and its importance in practice.

Table of contents

Chemical properties of caustic soda

Caustic soda is an aqueous solution of sodium hydroxide (NaOH), a strong base that dissociates completely in water. This gives it its characteristic chemical properties.

- pH value: Caustic soda has a pH value of about 13-14, depending on the concentration.

- Appearance: Clear, colorless liquid.

- Solubility: Caustic soda is completely soluble in water and strongly exothermic when diluted.

- Reactivity: Reacts with acids to form water and a salt, with aluminum to form hydrogen, and attacks organic substances.

Production of caustic soda

Caustic soda is produced industrially by electrolysis of sodium chloride (common salt) in chlor-alkali electrolysis plants.

Chlor-alkali electrolysis process:

Membrane process:

- Produces high-purity caustic soda with concentrations of up to 32 %.

- Uses a semi-permeable membrane to separate the products (chlorine, hydrogen and caustic soda).

Diaphragm method:

- Produces caustic soda with lower purity and concentration.

Mercury process:

- Historical process, now largely replaced due to environmental concerns.

Applications of caustic soda in water and wastewater technology

Caustic soda plays a central role in various water and wastewater treatment processes:

1. pH value regulation and neutralization

Caustic soda is often used to neutralize acidic waste water and to control the pH value.

Application:

- Neutralization of acidic wastewater before discharge into the public sewer system or a body of water

- pH adjustment in biological wastewater treatment plants to create optimum conditions for microorganisms.

- As a neutralizing agent for the formation of hydroxide flocs in CP systems

Photo: Mixing section of our ALMA Neutra neutralization system with pH-controlled neutralization

2. cleaning and disinfection processes

Caustic soda is a key component of many industrial cleaning processes, especially CIP (cleaning in place).

Application:

- Removal of deposits and biofilms in pipes, heat exchangers and membrane systems.

- Neutralization of acidic cleaning residues.

Concentrations of use:

- Typically 0.5-5 %, depending on the type of soiling and the materials of the system.

3. regeneration of ion exchangers

In softening and demineralization plants, as well as selective ion exchangers, caustic soda is used for the regeneration of anion exchangers is used.

- Procedure:

- Caustic soda displaces the anions bound to the ion exchanger (e.g. sulphates, nitrates, chlorides) and restores the exchange capacity.

- Concentrated solutions of 4-10 % NaOH are typically used.

Photo: Our ALMA ION ion exchanger system with upstream ALMA FIL multi-layer filters

Challenges and safety aspects when handling caustic soda

The use of caustic soda poses technical and safety challenges:

1. exothermic reaction on dilution

Problem:

- The dilution of concentrated caustic soda with water is highly exothermic and can lead to boiling delay and splashing.

Solution:

- Always stir caustic soda slowly into water, never the other way around.

2. corrosion of materials

Problem:

- Caustic soda attacks certain metals (e.g. aluminum, zinc) and organic substances.

Solution:

- Use of chemical-resistant materials such as stainless steel (V4A), plastics (e.g. PE, PP, PVC) or PTFE.

3. health and environmental risks

Problem:

- Caustic soda is highly corrosive and can cause severe burns on skin contact or inhalation.

- Discharge into water bodies can lead to drastic pH shifts and ecological damage.

Solution:

- Use suitable personal protective equipment (PPE), e.g. chemical protective gloves, safety goggles and face protection.

- Set up emergency showers and eyewash facilities nearby.

Equipment for the safe handling of caustic soda

Special systems and equipment are required to ensure the safe storage, dosing and use of caustic soda:

1. storage

Container:

- Made from chemical-resistant materials such as HDPE or stainless steel.

- Equipped with ventilation systems to prevent pressure build-up due to gas development.

Temperature control:

- Avoid temperatures below 15 °C to prevent crystallization of concentrated solutions (>50 %).

2. dosing systems

Components:

- Magnetically coupled centrifugal pumps or diaphragm pumps to prevent leaks.

- Flow meters and pH sensors for precise dosing.

Automation:

- Integration into process control systems for precise control and monitoring.

3. safety equipment

Overflow protection:

- Sensors to prevent overfilling in storage tanks.

Neutralization systems:

- Installation of neutralization basins for emergencies to safely treat accidentally released caustic soda.

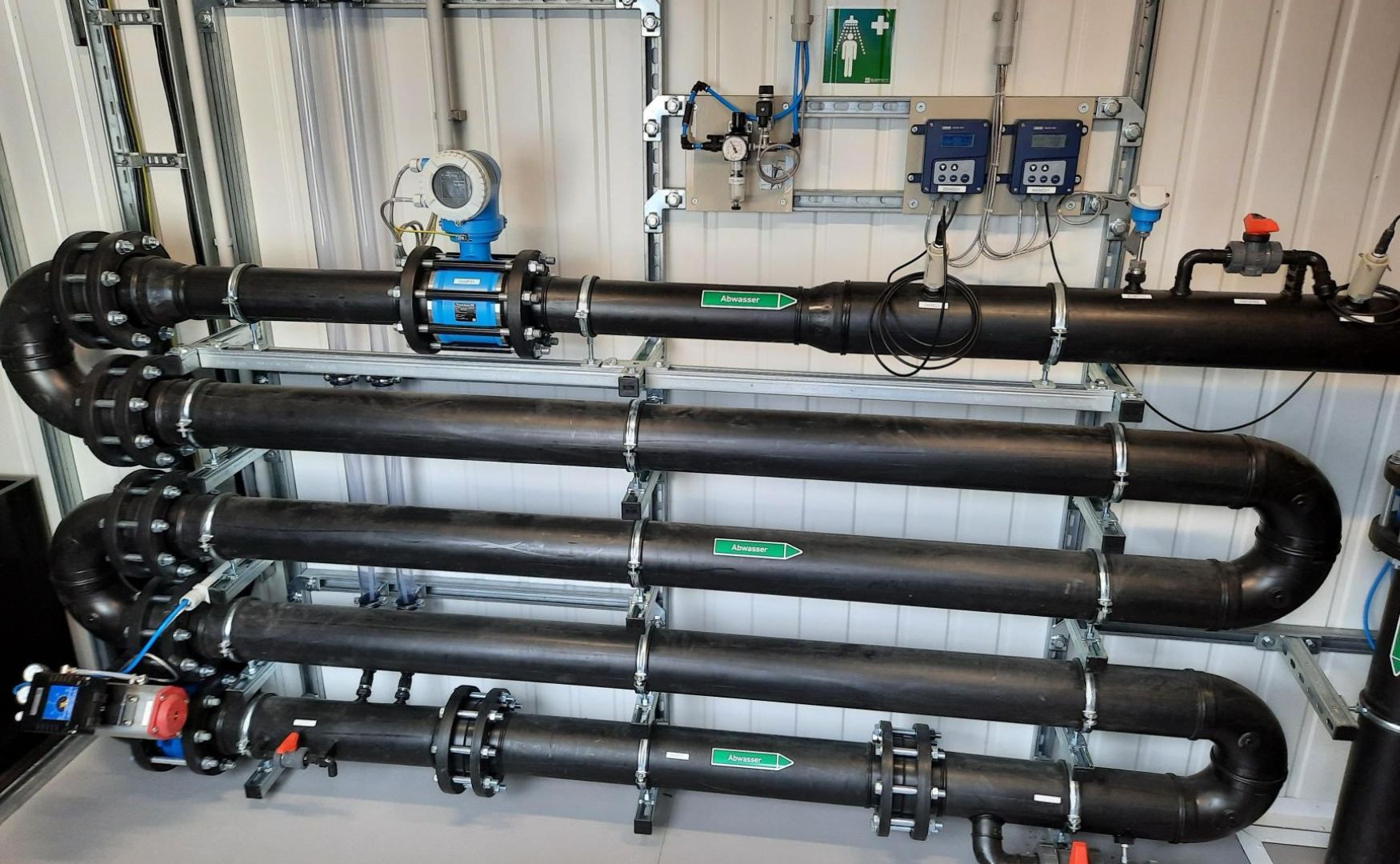

Photo: IBC dosing station for caustic soda and sulphuric acid for our neutralization system with WHG collection tray in the ALMA Modul technical room container

Conclusion

Caustic soda is a versatile and indispensable chemical in water and wastewater technology. Its applications range from the neutralization of acidic wastewater and the regeneration of ion exchangers to heavy metal precipitation and neutralization in CP systems. At the same time, handling caustic soda requires a high level of technical expertise and safety awareness. With modern systems, automated dosing systems and strict safety precautions, caustic soda can be used efficiently and safely to make industrial processes sustainable and environmentally friendly.

For further information on our products, please feel free to contact us at any time!