Boiler scale refers to deposits that form on the inner walls of boilers and heat exchangers when hard water is fed into the boiler without sufficient treatment. These deposits usually consist of calcium and magnesium compounds as well as other minerals that precipitate out of the water at high temperatures. Scale is a serious problem in steam boiler systems as it significantly impairs heat transfer, increases energy consumption and shortens the service life of the system.

Table of contents

Formation of scale

Scale is caused by the precipitation of hardness formers such as calcium and magnesium salts, which are contained in untreated water. When the water in the boiler is heated, it evaporates, while the dissolved salts remain behind and are deposited on the boiler walls. These deposits are exacerbated by high temperatures and pressure conditions in the boiler.

The most important scale components are

- Calcium carbonate (CaCO₃): The most common mineral in scale, which forms when hard water is heated.

- Calcium sulphate (CaSO₄): Forms at high temperatures and causes particularly hard deposits.

- Magnesium salts: Compounds such as magnesium hydroxide, which also contribute to the formation of scale.

Photo: State-of-the-art steam boiler system

Problems caused by scale

Scale acts like an insulator and reduces the efficiency of heat transfer in the boiler. This leads to several serious problems:

- Increased energy consumption: As the scale hinders heat transfer, more energy has to be used to generate the same amount of steam.

- Overheating and material damage: Scale can lead to overheating of the metal surfaces, which ultimately leads to damage to the boiler structure and, in the worst case, to cracks and leaks.

- Increased maintenance costs: Scale removal is costly and requires regular maintenance to keep the system in a safe and efficient condition.

- Shorter service life of the system: Scale deposits can lead to faster wear of the boiler and its components, which means that the system has to be replaced prematurely.

Prevention and removal of scale

Comprehensive boiler water treatment is required to prevent the formation of scale. This includes both the treatment of the feed water and the treatment of the boiler water during operation.

1. softening - ALMA ION

Reliable water softening is crucial to prevent the formation of scale caused by calcium and magnesium ions. Our ALMA ION softening systems work on the basis of ion exchange resins, which remove hardness formers from the feed water. This results in soft water with a hardness level of almost 0 °dH, which is ideal for use in steam boiler systems.

The ALMA ION softening systems offer:

- Automatic regeneration: To ensure uninterrupted operation.

- High-performance resins: For a long service life and high capacity.

- Fully automatic control: monitoring and control systems for precise control of water hardness.

Photo: ALMA ION water softener for industrial applications

2. degassing and oxygen removal

Oxygen is a major cause of corrosion in boiler systems. Mechanical degassing is a widely used method for removing oxygen and other gases from the feed water. The water is heated to a temperature at which dissolved gases are expelled. In addition, chemical oxygen binders such as ALMA AQUA oxygen binders are used to neutralize residual oxygen and prevent corrosion.

3. alkalization

To avoid acidic corrosion in the boiler, the boiler water must have a slightly alkaline pH value. Alkalizing agents, as used in the ALMA AQUA Boiler-product range, help to keep the pH value in the optimum range. This protects the metallic surfaces of the boiler from corrosion and ensures a longer service life for the system.

4. hardness stabilization

Even with optimally softened water, residual hardness and dissolved salts in the boiler can lead to deposits. Hardness stabilizers bind these salts and prevent them from precipitating. This ensures a continuously high heat transfer and reduces energy consumption. The ALMA AQUA boiler-product range offers special hardness stabilizers that are matched to the respective boiler type and feed water.

5. sludge separation and defoaming

Suspended solids and impurities can lead to foaming and deposits that impair the efficiency of the boiler. Defoamers prevent foaming and ensure better separation of water and steam. In addition, sludge separation supports the removal of undissolved substances from the boiler before they can cause deposits.

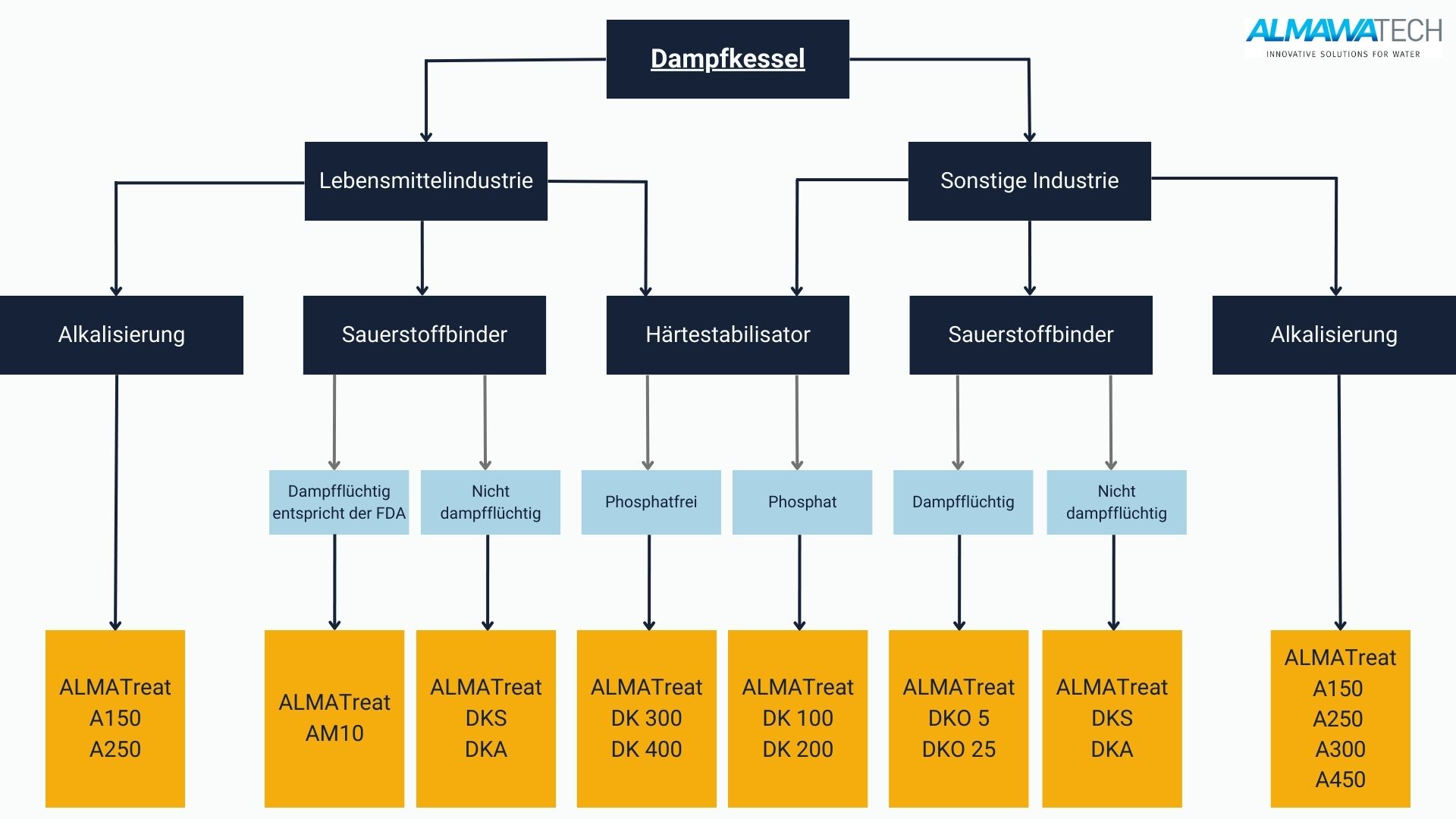

Products to support boiler systems - ALMA AQUA Boiler

To avoid these problems, ALMAWATECH offers a wide range of equipment and treatment systems that have been specially developed for steam boiler systems:

Boiler water systems require special chemicals to prevent corrosion, deposits and steam contamination. The ALMA AQUA Boiler-products offer comprehensive solutions for boiler water treatment:

Corrosion inhibitors: They prevent the oxidation of metal surfaces in the boiler systems and extend the service life of the system components.

Hardness stabilizers: These chemicals prevent the formation of scale and limescale deposits on the heat exchanger surfaces, which improves heat transfer efficiency and reduces energy consumption.

Defoamers: Defoamers prevent the formation of foam in the boiler water, which can lead to steam contamination and impair boiler operation.

Dispersants: They keep suspended solids in suspension in the water and prevent particles from settling on heat exchangers and pipes.

Oxygen binders: These remove dissolved oxygen from the water to prevent corrosion in boiler and condensate systems.

Alkalizing agents: These agents are used to increase the pH value in the boiler water and improve the conditions for corrosion prevention.

Photo: Product overview of various operating materials for steam boiler systems (ALMA AQUA boilers)

Advantages of professional boiler water treatment

Efficient boiler water treatment has several advantages for the operation and cost-effectiveness of the system:

- Increased operational reliability: Deposits and corrosion are prevented, which extends the service life of the boiler and minimizes the risk of malfunctions.

- Energy efficiency: By preventing scale and deposits, heat transfer remains efficient, reducing energy consumption and operating costs.

- Reduced maintenance costs: The need for cleaning and repair work is reduced by effective boiler water treatment.

- Environmental friendliness: The efficient operation of the boiler leads to a reduction in fuel consumption and thus to a reduction in CO₂ emissions.

Conclusion

Scale poses a significant risk to the efficiency and safety of steam boiler systems. Professional boiler water treatment with the right products, such as our ALMA ION softening systems and ALMA AQUA boiler operating fluids, is crucial to prevent the formation of deposits, extend the service life of the system and minimize energy consumption. The right combination of softening, hardness stabilization and corrosion protection can ensure the long-term efficiency of the boiler system.

For further information on our products, please feel free to contact us at any time!