A biogas plant is a technical facility for the anaerobic treatment of organic waste and wastewater in which biogas is produced in the absence of oxygen. This biogas, which consists mainly of methane (CH₄) and carbon dioxide (CO₂), is then used to generate energy. The anaerobic process enables the utilization of organic substances from wastewater, such as sludge from the food industry, dairies and the sugar industry. The use of biogas plants not only offers companies a sustainable disposal solution, but also an opportunity to increase their energy self-sufficiency and reduce operating costs.

Table of contents

How a biogas plant works

The operation of a biogas plant is based on the anaerobic decomposition of organic substances by microorganisms. The process takes place in a closed anaerobic reactor in which various groups of bacteria gradually decompose the organic waste in the absence of oxygen. The decomposition takes place in several phases:

Hydrolysis: Here, complex organic substances such as carbohydrates, proteins and fats are broken down into smaller molecules.

Acidogenesis: In this step, microorganisms produce volatile fatty acids, alcohols and gases such as hydrogen and carbon dioxide from the decomposed substances.

Acetogenesis: The volatile fatty acids are further converted into acetic acid, hydrogen and carbon dioxide.

Methanogenesis: Finally, methanogens convert the acetic acid and gases into methane and carbon dioxide, which is used as biogas.

The efficiency of the biogas process depends on the composition of the substrate, the temperature and the retention time in the digester.

Use of biogas plants in wastewater treatment

Biogas plants are often used in industrial wastewater treatment, especially for wastewater with a high organic load. This includes wastewater from the food and beverage industry, dairies, sugar industry and abattoirs, which contain high amounts of organic material that is ideal for biogas production.

Food industry: Waste water from food processing, such as sweet whey or waste from meat processing, contains high quantities of fats, proteins and carbohydrates, which can be converted into biogas by anaerobic fermentation.

Dairies: Dairies produce waste water with a high fat and protein content, which can be treated efficiently by a biogas plant.

Sugar industry: Waste water from sugar production contains large quantities of organic carbohydrates, which are ideal for biogas production.

Anaerobic processes in practice

Anaerobic processes are particularly common in the treatment of highly organically contaminated wastewater and organic waste in various industries. The most important applications include

1. anaerobic wastewater treatment

Anaerobic reactors are often used in food and beverage industries, dairies, paper mills and biogas plants. biogas plants to break down organic substances in wastewater and simultaneously generate energy in the form of biogas. Typical reactors for anaerobic processes are

UASB reactors (Upflow Anaerobic Sludge Blanket):

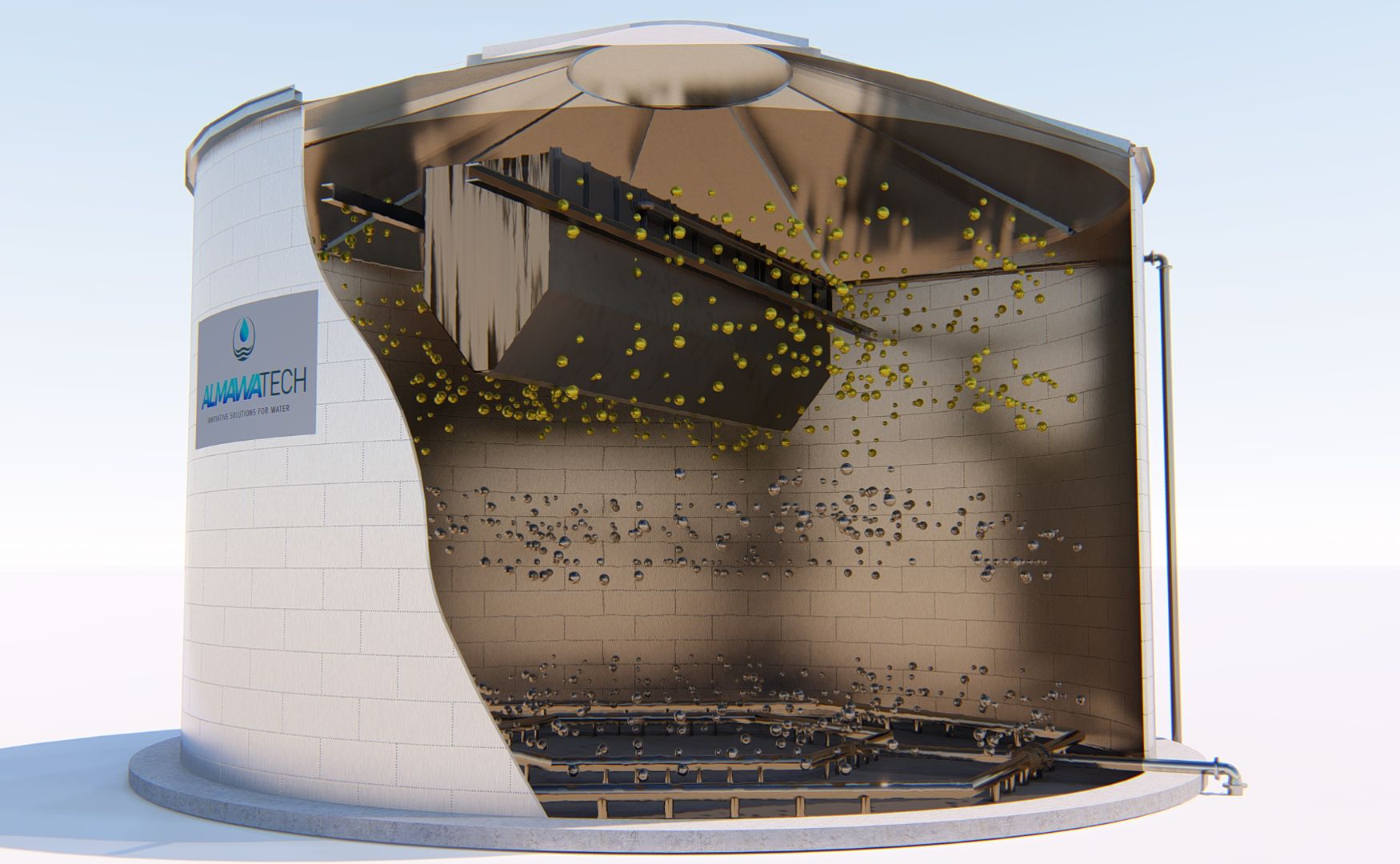

The UASB reactor (Upflow Anaerobic Sludge Blanket) is an anaerobic reactor technology characterized by efficient wastewater treatment and biogas production. The wastewater flows in a counter-current principle from the bottom to the top of the reactor, where it meets a sludge layer consisting of granulated anaerobic microorganisms. These microorganisms break down the organic substances in the wastewater under anaerobic conditions and produce biogas, which consists mainly of methane and carbon dioxide.

Technical specifications:

- Flow direction: From bottom to top (upflow)

- Hydraulic dwell time: Typically between 6 and 12 hours

- Organic loading rate: Up to 10 kg COD/m³-d

- Temperature range: Can be operated in both mesophilic (30-40°C) and thermophilic (50-60°C) areas

- Gas production: 0.25 to 0.35 m³ of biogas per kg of degraded COD

Photo: Schematic representation of our ALMA BIO UASB reactor

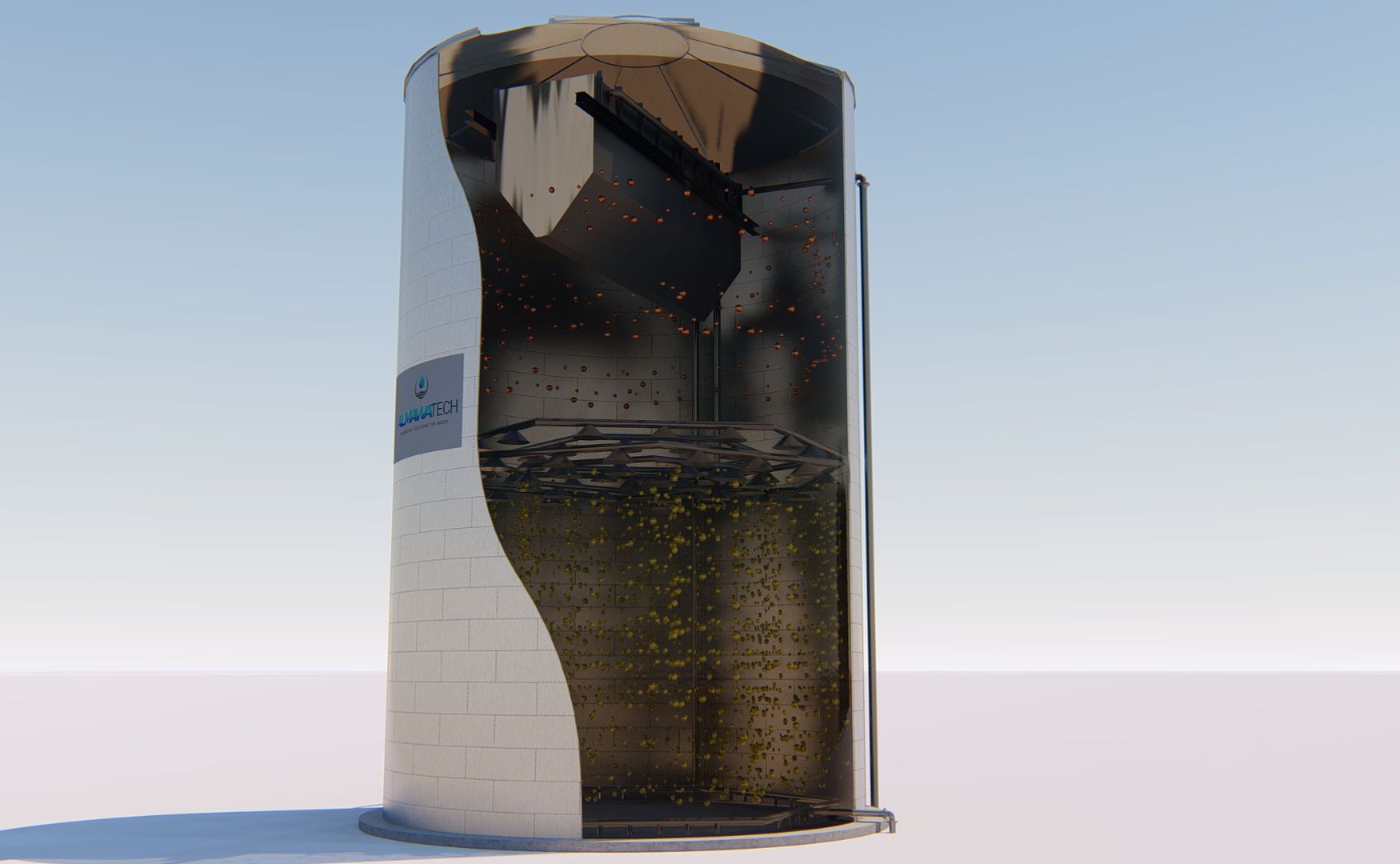

EGSB reactors (Expanded Granular Sludge Bed):

The EGSB reactor (Expanded Granular Sludge Bed) is a further development of the UASB reactor and is characterized by a higher flow rate and better mixing. In the EGSB reactor, the wastewater is fed through the granulated sludge layer at a higher speed, which reduces the hydraulic retention time and increases the organic load. This improved fluid circulation and expansion of the sludge bed makes the reactor more efficient, especially for wastewater with a very high organic load.

Technical specifications:

- Flow direction: From bottom to top, similar to the UASB reactor, but with a higher flow velocity.

- Hydraulic retention time: Typically between 1 and 6 hours, depending on the wastewater composition.

- Organic loading rate: Up to 30 kg COD/m³-d

- Reactor height: EGSB reactors are typically higher than UASB reactors, which leads to better separation of sludge and wastewater.

- Gas production: Similar to the UASB reactor, with a gas production of around 0.3 to 0.35 m³ of biogas per kg of degraded COD.

Photo: Schematic representation of our ALMA BHU BIO EGSB reactor

Gas mixing reactors:

Photo: Photos of our anaerobic gas mixing reactor ALMA BHU GMR

Advantages of anaerobic processes

High energy efficiency:

- By generating biogas, anaerobic wastewater treatment can cover a large part of a plant's energy requirements or even produce surplus energy.

Lower oxygen demand:

- As anaerobic processes do not require oxygen, they are particularly advantageous in areas where the energy required for aeration in aerobic processes is high.

Reduction of sludge:

- Compared to aerobic processes, anaerobic systems produce less excess sludge, which reduces the costs for sludge treatment and disposal.

Degradation of poorly degradable organic compounds:

- Anaerobic microorganisms are also able to utilize organic substances that are difficult to break down, which makes these processes particularly valuable in certain industrial waste.

Challenges of anaerobic processes

Longer response times:

- Anaerobic processes are often slower than aerobic processes, which can lead to longer residence times and larger reactor volumes.

Sensitivity to toxic substances:

- Anaerobic microorganisms are more sensitive to toxic substances in wastewater, which can lead to process disturbances. This requires careful monitoring and control of the feed concentrations.

Conclusion

A biogas plant is an ideal solution for recycling organic wastewater, especially in the food industry, dairies and sugar production. In addition to efficient wastewater treatment, anaerobic digestion enables the production of energy in the form of biogas, which both reduces operating costs and makes an important contribution to sustainability.

For further information on our products, please feel free to contact us at any time!