An antiscalant is a chemical that is used in industrial water treatment plants, particularly in membrane processes such as reverse osmosis (RO) and nanofiltration (NF)to prevent the formation of deposits or scaling on the membranes. Scaling occurs when dissolved salts such as calcium carbonate (CaCO₃), calcium sulphate (CaSO₄), barium sulphate (BaSO₄) or silicon dioxide (SiO₂) precipitate and deposit on the membranes. This leads to a deterioration in membrane performance, higher energy requirements and ultimately to shorter maintenance intervals.

The use of antiscalants prevents or delays the formation of these deposits, resulting in longer operating times, lower maintenance requirements and consistent filtration performance. They are essential for the efficiency and reliability of water treatment systems based on membrane technology and make a decisive contribution to the service life of the membranes.

Table of contents

Technical background

Scaling occurs when the concentration of certain ions in the water exceeds the solubility limit, which leads to crystallization and deposition on the membranes. Antiscalants work in the following ways:

Threshold inhibition: Antiscalants increase the solubility of the salts contained in the water so that they can be present in higher concentrations without precipitation.

Crystal growth modification: They change the growth structure of the crystals, which leads to the formation of smaller and less adhesive crystals that are carried further in the water flow.

Dispersion: Antiscalants prevent crystals and particles from clumping together by disrupting the interactions between these particles so that they remain suspended in the water more easily and can be removed from the system.

Application in practice

Antiscalants are widely used, particularly in membrane processes such as reverse osmosis and nanofiltration, where the formation of deposits can severely impair filtration performance. They are added to the feed water before membrane filtration to prevent the crystallization process and minimize the deposition of salts on the membranes.

Typical areas of application:

- Reverse osmosis (RO) systems: Antiscalants prevent the formation of limescale and salt deposits on the membranes, which would lead to a drop in performance and increased pressure losses.

Photo: High-pressure reverse osmosis system in stainless steel design(ALMA OSMO Process)

- Nanofiltration (NF): Here, antiscalants are used to maximize the efficiency of the separation performance and extend the service life of the membranes.

- Seawater desalination: Antiscalants play a crucial role in preventing scaling in seawater desalination plants, where the water has particularly high concentrations of dissolved salts.

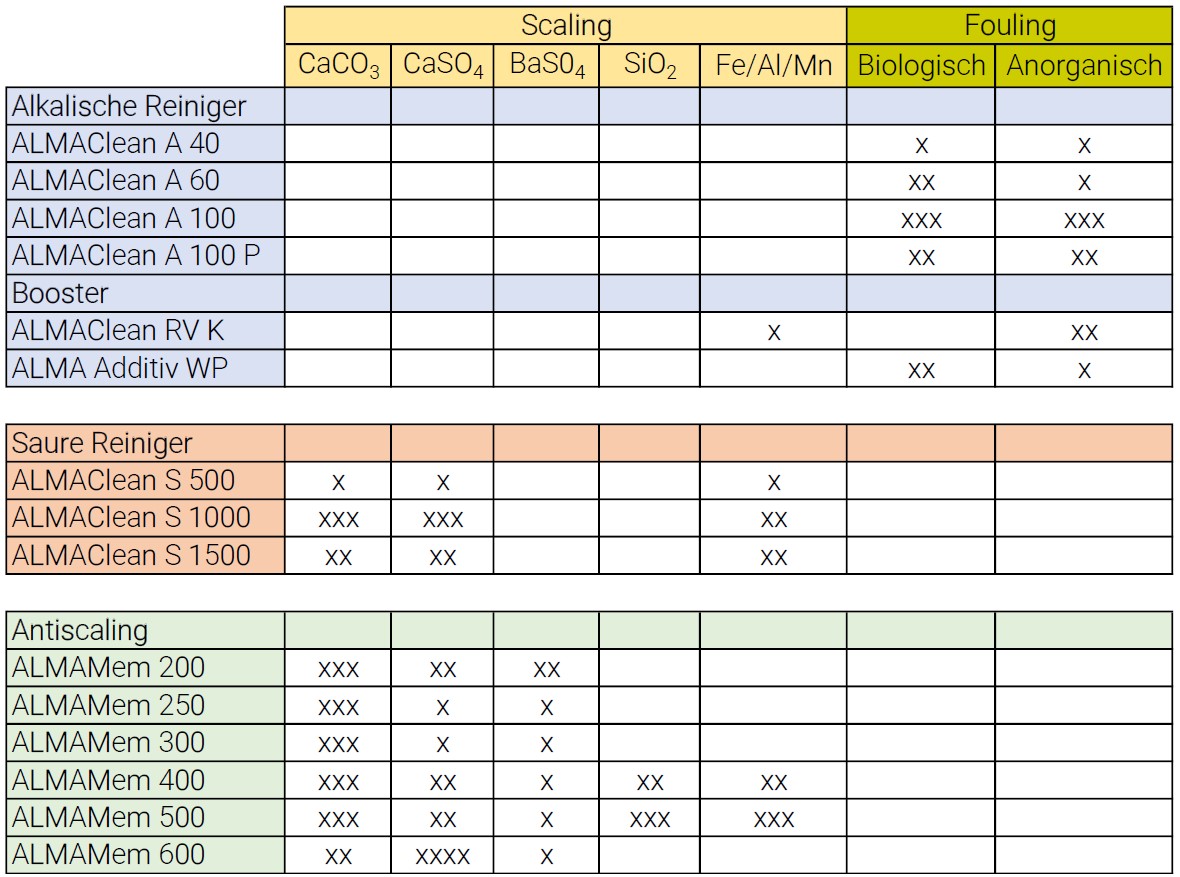

Antiscalant from ALMAWATECH: ALMA AQUA membrane

The antiscalants from ALMAWATECH from the product series ALMA AQUA Membrane are specially developed to maximize the performance and service life of membrane systems. Our antiscalants offer:

- Effective protection against deposits of calcium carbonate, calcium sulphate, barium sulphate and silicate.

- Optimized dosing to reduce maintenance and extend operating times.

- Universal compatibility with various membrane types, allowing them to be used in a wide range of water treatment systems.

With our ALMA AQUA membrane cleaners, we also offer special solutions for the regeneration and cleaning of membranes to ensure optimum operating performance even with heavily loaded systems. You can find more information about our products here: ALMA AQUA Membrane.

Photo: Product overview of our membrane cleaners and antiscalants from the ALMA AQUA Membrane product series

Advantages of using antiscalants

Extended service life of the membranes: By preventing deposits, the membranes remain functional for longer, resulting in lower operating costs and higher profitability.

Optimization of filtration performance: Antiscalants prevent the flow and filtration performance from being impaired by deposits, so that the system operates continuously at maximum efficiency.

Minimization of cleaning cycles: The use of antiscalants reduces the need for frequent chemical cleaning, saving time and resources.

Challenges and operating instructions

Precise dosage: The correct dosage of antiscalants is crucial to achieve the desired effects. Incorrect dosing can lead to either insufficient protection or undesirable side effects.

Continuous system monitoring: Regular monitoring of the system and the water parameters is necessary to ensure the effectiveness of the antiscalants and to detect the occurrence of scaling at an early stage.

Conclusion

Antiscalants are essential chemicals in membrane filtration and help to prevent scaling and maximize the efficiency and service life of membrane systems. With the ALMA AQUA membrane-products from ALMAWATECH, we offer customized solutions that optimally protect your membrane systems while reducing operating costs.

For further information on our products, please feel free to contact us at any time!