Many industrial processes produce wastewater with pH values that deviate significantly from neutrality. Strong acids or alkalis enter the wastewater through production or cleaning processes and lead to acidic or alkaline wastewater streams. Without treatment, these could neither be discharged into public sewer networks nor directly into bodies of water. Precise pH adjustment is therefore necessary to protect the environment, infrastructure and biological treatment stages.

Neutralization systems perform this task by reducing the pH value to the legally required range, usually between 6.5 and 9.5. This makes them one of the most frequently used physico-chemical processes in industrial wastewater technology. They range from simple neutralization tanks with manual chemical dosing to highly automated systems with redundant measurement and control technology, online documentation and connection to process control systems.

Photo: Our ALMA Neutra neutralization system in container design with mixing and equalization tank and grease separator

Table of contents

Tasks and objectives of a neutralization system

The core task of every neutralization plant is to comply with the legal limits for the pH value as defined in the German Wastewater Ordinance (AbwV) and the respective indirect discharger ordinances. In addition, these systems perform an important protective function for the entire infrastructure. Pipes, pumps and fittings are protected from corrosion and deposits by targeted pH regulation. Neutralization also protects downstream biological processes such as activated sludge or anaerobic reactors, which react very sensitively to excessively acidic or alkaline inflows.

Last but not least, pH correction enables cost-efficient overall treatment of the wastewater. Precise control allows chemicals to be dosed exactly, which reduces consumption and therefore also operating costs.

Structure and mode of operation

A typical neutralization system consists of several main components:

Equalizing tank: Receiving the waste water with agitators or injectors for homogenization.

pH measurement and control: Online probes continuously monitor the pH value and control the chemical dosing.

Dosing systems: Storage tanks, pumps and fittings for acids (e.g. sulphuric acid, hydrochloric acid) or alkalis (e.g. caustic soda, milk of lime).

Reaction tank: Design according to hydraulic residence time, mixing energy and chemical reaction kinetics.

Safety technology: overfill protection, emergency neutralization, bypass lines.

Logging: Data recording to provide evidence to the authorities.

Photo: IBC dosing stations installed on a WHG collection tray in ALMA module

Process for neutralizing waste water

Traditionally, strong mineral acids such as sulphuric acid or hydrochloric acid are used when alkaline wastewater with high pH values is present. The advantage of this method lies in the fast reaction kinetics and easy dosing. At the same time, however, there are increased requirements for occupational safety and corrosion protection, as the chemicals are highly corrosive.

If the wastewater is acidic, alkaline solutions such as sodium hydroxide, potassium hydroxide or milk of lime are used. Although caustic soda is reliable and easy to dose, it causes comparatively high operating costs. Milk of lime offers a more cost-effective alternative here, but requires careful design, as the formation of calcium carbonate sludge can lead to deposits in pipes and reaction tanks.

In many companies, the composition of the wastewater fluctuates between acidic and alkaline load peaks. In such cases, neutralization tanks with double-sided control are used, which can be fed with both acids and alkalis. Precise measurement and control technology is crucial here in order to avoid overdosing.

Photo: Neutralization reactor made of stainless steel with pH control (system: ALMA Neutra)

CO₂ neutralization as an alternative method

In recent years, neutralization with carbon dioxide has become increasingly important. It offers a safe, sustainable and, in many applications, economical alternative to the classic dosing of mineral acids.

The functional principle is based on the fact that carbon dioxide in water reacts to form carbonic acid, which in turn releases protons and thus lowers the pH value. The advantage of this reaction method lies in the natural buffering: the formation of hydrogen carbonate means that acidification is practically impossible. Neutralization is therefore gentler and more controlled than with sulphuric acid or hydrochloric acid.

Technically, the CO₂ is usually taken from cylinder bundles or tanks and injected into the wastewater via injectors, gas lances or fine-bubble diffusers. As with conventional methods, the process is controlled via a pH probe and a control valve. In some industrial sectors, CO₂ can even be used directly from secondary processes, which reduces operating costs and improves the CO₂ balance.

The advantages are manifold: on the one hand, the dangers of acid handling are eliminated, which significantly improves occupational safety. Secondly, the corrosion load on the system technology is reduced. In addition, the reduced risk of over-acidification means that operation is much more stable. However, there are limitations in the case of very high alkalinity or wastewater with extremely high throughputs, as in these cases the amount of CO₂ required can be economically unfavorable.

Photo: ALMA Neutra CO2 neutralization plant in container design

Design criteria

The design of a neutralization system depends heavily on the specific operating conditions. The main parameters are the hydraulic load, the composition of the wastewater and the expected fluctuations. Reaction tanks must be dimensioned in such a way that sufficient retention time is available for complete neutralization.

The choice of dosing technology depends on the neutralizing agents used: While acids and alkalis are dosed via chemical-resistant pumps, CO₂ is introduced in gaseous form via pressure lines and feed devices. The choice of material also plays a decisive role. Depending on the aggressiveness of the wastewater and the chemicals used, plastics such as PP and PE or stainless steel are used.

Areas of application

Neutralization systems can be found in almost all industrial sectors. In the chemical industry, highly acidic or alkaline process wastewater is treated, while acidic pickling solutions are neutralized in metal processing. Neutralization is also an integral part of CIP cleaning cycles in the food and beverage industry. In municipal sewage treatment plants, neutralization is often used to preset the pH value in order to protect biological treatment stages from harmful fluctuations.

Conclusion

Neutralization systems are indispensable for compliance with environmental regulations, the protection of plant technology and economical operation. While traditional methods using acids and alkalis are still widely used, CO₂ neutralization is increasingly establishing itself as a safe and sustainable alternative. Its advantages include easier handling, greater occupational safety and a reduced risk of acidification.

The choice of a suitable process always depends on the specific conditions of the operation. The decisive factor is a careful plant design that takes into account both the chemical properties of the wastewater and the operational requirements. Only in this way can operational safety, efficiency and sustainability be optimally combined.

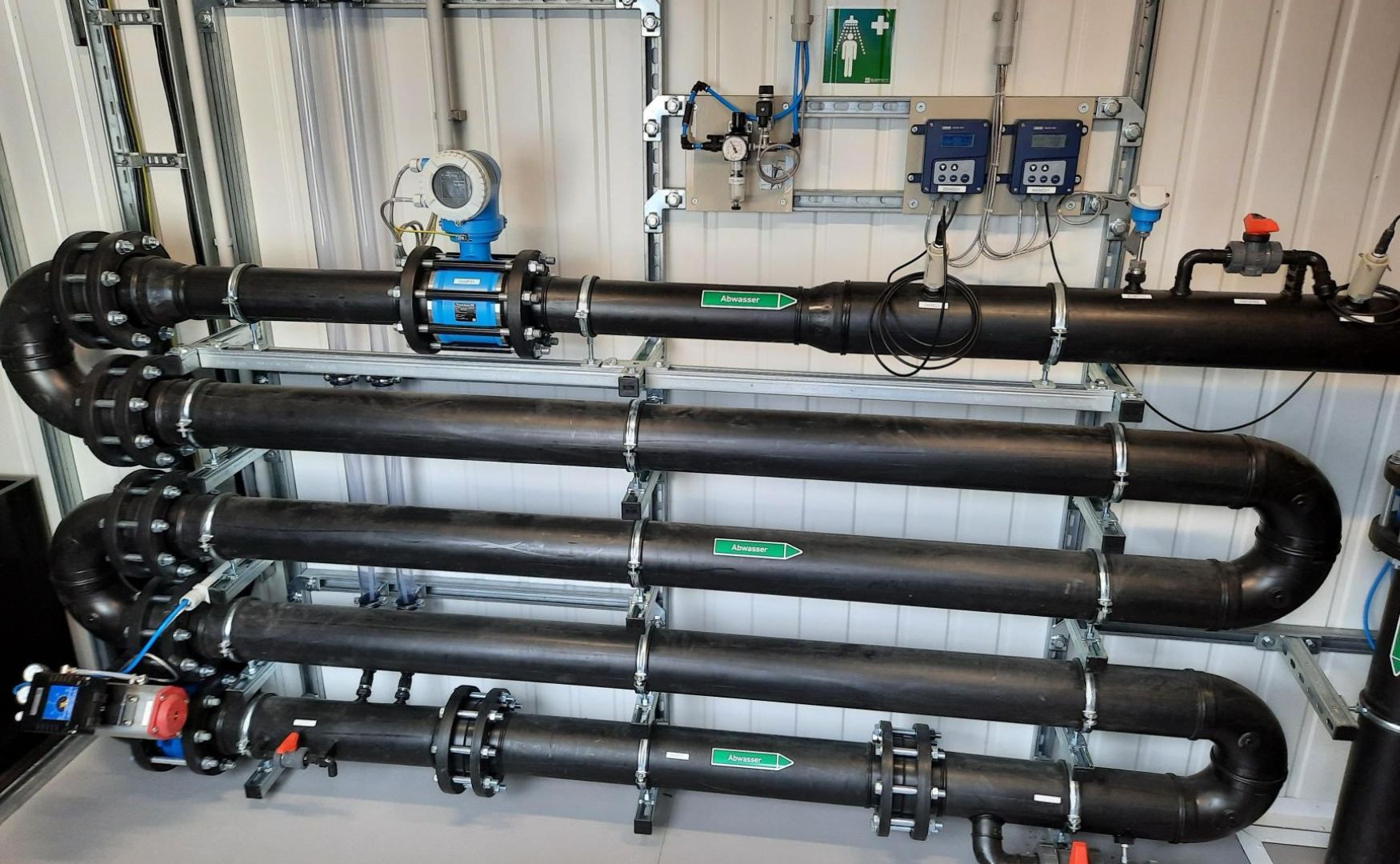

Photo: Loop reactor with pH control made of polyethylene, installed in the ALMA module