In times of increasing environmental requirements and rising costs, implementing a water recycling program is not only a crucial step towards sustainability, but also a strategic measure to reduce costs and increase efficiency. A well thought-out plan for water recycling helps companies to reduce water consumption, cut wastewater volumes and sustainably reduce operating costs.

A well-planned water recycling system requires a comprehensive analysis and implementation of suitable technologies. It starts with a detailed inventory and ends with continuous monitoring and optimization of the system. In this blog post, we present a structured approach that will show you the way to a successful water recycling project in your company.

Table of contents

Water audit and needs analysis

The first and most important step in implementing a water recycling program is a comprehensive water audit. The aim of an audit is to record your company's water consumption in detail and to identify the main sources of water consumption as well as the sources of wastewater. This analysis provides valuable data that serves as the basis for all further steps.

The following aspects should be considered in a water audit:

- Water input: How much water is used in your company? Which processes consume the largest amount of water?

- Water discharge: What quantities of wastewater are produced and what is their composition? What pollutants are contained in the wastewater that need to be treated or removed?

- Consumption analysis: Are there processes in which water is used inefficiently? Where is there potential to reduce water consumption or reuse it?

A detailed audit not only allows you to better understand the current situation, but also to identify potential savings. A water audit forms the basis for the next steps in the water recycling program and enables clear objectives to be set.

Definition of measurable targets for water recycling

Based on the results of the water audit, clear and measurable goals should be defined for your water recycling program. These targets provide the framework and help to monitor and measure the success of the project. Possible targets could be

- Reduction of total water consumption by a certain percentage.

- Reduction of waste water volumes by reusing process water.

- Improvement of water quality after treatment for reuse in sensitive processes.

Realistic and achievable targets are crucial for long-term success. They should be based on the individual needs and possibilities of your company and at the same time be ambitious enough to achieve significant savings and environmental benefits.

Choosing the right technologies

Selecting appropriate technologies is a critical step in implementing a water recycling program. There are a variety of water recycling technologies that vary depending on the industry and specific requirements. Some of the most common water treatment and reuse technologies are:

Processes and technologies for water reuse

Membrane filtration & reverse osmosis

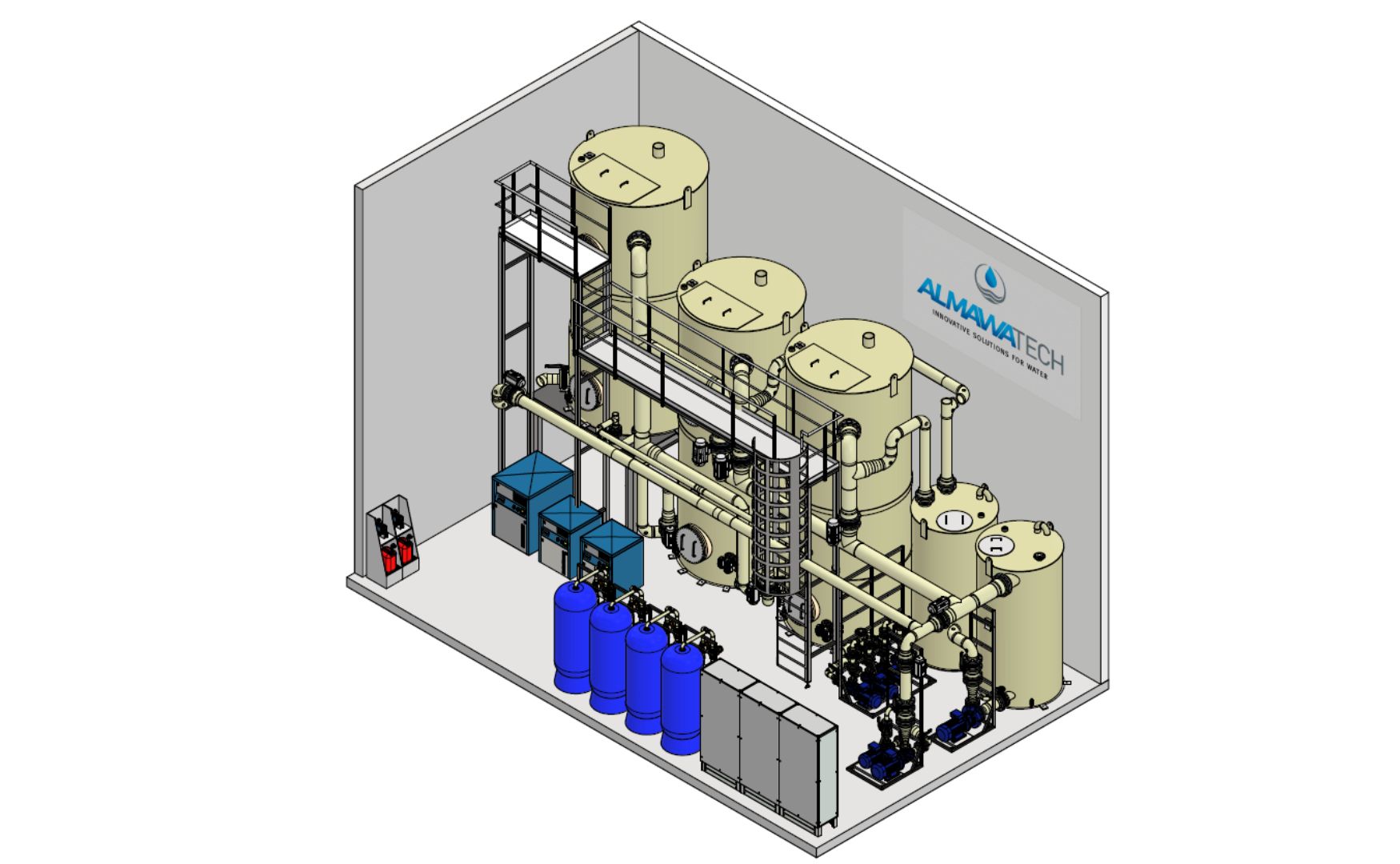

Photo: ALMA BHU BiosS-Treat reverse osmosis system

Membrane processes, in particular reverse osmosisare state-of-the-art water treatment technologies that are ideal for removing undissolved substances, dissolved impurities and trace substances from wastewater and process water. These processes are primarily used in industries that require particularly high water quality, such as

- Food and beverage industry: Membrane technologies are used here to ensure product purity and to produce process water for sensitive production steps.

- Chemical industry: Membrane processes help to remove harmful chemicals and impurities from wastewater streams before the water is reused or discharged.

- Pharmaceutical industry: In this sector, the production of high-purity water is crucial in order to meet the strict regulatory requirements.

Advantages of membrane processes and reverse osmosis

High purification performance: Reverse osmosis can remove even the smallest particles, ions and dissolved substances from the water, producing ultrapure water that is suitable for demanding applications in industry and production.

Compact design: Membrane systems are space-saving and can be easily integrated into existing systems. Thanks to their modular design, they are also scalable so that they can be adapted to the company's individual requirements and capacities.

Biofiltration

Photo: Biofiltration ALMA BioFil Compact

Biofiltration is a biological process for cleaning wastewater that is particularly suitable for wastewater with high residual concentrations of organic compounds and nitrogen. These compounds can impair the operation of reverse osmosis plants and make them uneconomical, as they significantly increase the risk of biofouling. Biofiltration systems, such as the ALMA BioFil Compactare therefore often used as pre-treatment upstream of reverse osmosis systems to efficiently reduce organic compounds and nitrogen and optimize the performance of downstream membrane systems.

Field of application

Wastewater with high residual organic loads: Biofiltration is ideal for wastewater that still contains significant amounts of organic compounds after primary treatment (e.g. vapor condensates). These substances must be removed to prevent overloading or damage to the membranes in reverse osmosis systems.

Nitrogen-contaminated wastewater: Nitrogen compounds such as ammonium and nitrates can impair the operation of water treatment systems. Biofiltration contributes to the biological removal of nitrogen and efficiently treats the water before it is fed into further processes such as reverse osmosis.

Pre-treatment for reverse osmosis: The ALMA BioFil Compact is a frequently used biofiltration system that serves as a preliminary stage for. It reduces the content of organic and nitrogenous compounds, minimizing the risk of biofouling on the membranes and extending their service life.

Advantages

Effective reduction of organic pollutants: Biofiltration enables efficient carbon elimination by breaking down organic compounds through microbiological activity. This reduces the chemical oxygen demand (COD) and significantly improves the water quality.

Nitrogen removal: In addition to the reduction of organic pollutants, biofiltration also contributes to denitrification, a process in which nitrogen compounds are removed from the wastewater. This is particularly important for use in reverse osmosis systems, as nitrogen compounds can pollute the membrane systems.

Lower operating costs: Compared to other advanced technologies such as chemical oxidation processes or thermal treatments, biofiltration offers lower operating costs as it is based on natural biological processes and requires less energy and chemicals.

Optimization of membrane systems: Pretreatment with biofiltration significantly reduces the risk of biofouling in reverse osmosis systems. This extends the service life of the membranes and the maintenance intervals are extended, which lowers the overall costs of operating the system.

Precipitation & flocculation (CP systems)

Photo: CP system ALMA CHEM MCW

The precipitation and flocculation of wastewater using CP plants is a proven method for the pretreatment of wastewater, especially as preparation for downstream water recycling systems such as reverse osmosis. Our system, the ALMA CHEM MCWis specially designed for this application and ensures that wastewater containing high concentrations of organic compounds, heavy metals, AOX, hydrocarbons and suspended solids is efficiently pretreated. This significantly reduces the load on the reverse osmosis membranes and minimizes the risk of biofouling and scaling, which in turn extends the service life of the membranes and maximizes the efficiency of water treatment.

Field of application

The ALMA CHEM MCW is used in numerous industries in which water recycling by means of reverse osmosis plays a central role, including

- Electroplating: Wastewater from electroplating processes often contains heavy metals such as chromium, nickel or zinc, which can be effectively removed by precipitation.

Metalworking companies: Metalworking produces wastewater with high concentrations of oils, greases and metal particles, which can be pre-treated by CP systems.

Surface coating: Wastewater contaminated with chemical residues and solvents is produced here. CP systems help to remove these pollutants before discharge or further treatment.

River water treatment: In water treatment, CP systems are used to pre-treat river water in order to remove organic impurities and suspended solids before the water is further treated or used.

Material recycling: Recycling processes, particularly the recycling of metals and other materials, produce wastewater with complex chemical compounds. CP systems help to precipitate these substances efficiently and treat the wastewater.

Cosmetics industry: The manufacture of cosmetic products produces wastewater containing emulsions, surfactants and organic compounds that have to be treated using precipitation and flocculation processes.

Electronics and microelectronics: These sectors produce wastewater that is often contaminated with heavy metals, semiconductor materials and other specialty chemicals. CP systems contribute to safe and environmentally friendly treatment here.

Food industry: CP systems are also used in food processing, particularly in the context of water recycling, to remove organic substances, fats and suspended solids from wastewater and thus reduce water consumption.

Complementary treatment methods

In addition to precipitation and flocculation by the ALMA CHEM MCW, further treatment steps can also be integrated depending on the quality of the wastewater in order to increase the efficiency of the reverse osmosis process. reverse osmosis further optimized:

Multi-layer filter: These filter stages remove fine suspended solids and particles that may remain in the water after precipitation and flocculation. This protects the sensitive membranes of the reverse osmosis system from mechanical stress and improves the overall performance of the system.

Selective ion exchangers: In the case of particularly high concentrations of heavy metals or specific ions in wastewater, the use of selective ion exchangers may be necessary. These selectively remove unwanted ions and treat the water so that the downstream reverse osmosis can work optimally. Ion exchangers help to improve the water quality and prevent the membranes of the reverse osmosis from being impaired by high concentrations of metal ions.

Advantages of ALMA CHEM MCW as a pre-treatment

Efficient removal of difficult-to-treat contaminants: The ALMA CHEM MCW is particularly efficient at precipitating heavy metals, organic substances and suspended solids that are difficult to break down using biological processes. These pollutants are specifically removed from the wastewater in order to reduce the load on the reverse osmosis membranes.

Protecting and extending the service life of the membranes: Pre-treatment with ALMA CHEM MCW significantly reduces the risk of biofouling and mechanical stress on the membranes. This leads to a longer service life of the membranes and reduces the maintenance intervals and costs for the reverse osmosis system.

Scalability and flexibility: The ALMA CHEM MCW is flexibly adaptable and can be integrated into various water recycling systems as required. The technology is scalable and suitable for both small and large industrial applications that require pre-treatment prior to reverse osmosis.

Optimization of water recycling: By combining chemical-physical pre-treatment, multi-layer filters and ion exchangers, optimum water quality can be achieved for reverse osmosis. This not only improves the efficiency of water recycling, but also helps to conserve resources and reduce costs.

Selective ion exchangers

Photo: ALMA ION ion exchanger system

Field of application

Ion exchange systems are a proven and highly developed technology for removing impurities from water. They work on the basis of ion exchange resins, which replace specific ions in the water with other ions. Due to their ability to remove complex impurities and micropollutants, ion exchange resins are ideal for a wide range of applications in water and wastewater treatment. This technology is particularly used in industries that have extremely high water purity requirements, such as:

Electronics industry: High-purity process water is required here to protect sensitive electronic components from impurities that could impair product quality.

Solar industry: The production of solar panels requires extremely clean water to ensure that the sensitive surfaces are not damaged and the efficiency of the modules is maintained.

Metallurgy and electroplating: In metal finishing and electroplating, metal ions must be precisely controlled and removed to ensure high-purity surfaces.

Pharmaceutical industry: The production of pharmaceuticals and active ingredients also requires ultra-pure process water in order to avoid contamination and comply with the industry's strict regulations.

Selective ion exchange enables these industries to meet stringent water quality requirements while ensuring more environmentally friendly and efficient processes.

How the selective ion exchange works

Selective ion exchange is based on the ability of ion exchange resins to exchange specific ions from the water for harmless or desired ions. These resins can be tuned to specific contaminants to remove only selected ions while leaving others untouched. This makes the process particularly efficient for the targeted removal of trace substances or compounds that are difficult to break down.

Typically, cation exchangers are used to remove positively charged ions (such as calcium, magnesium, heavy metals) and anion exchangers to remove negatively charged ions (such as chloride, sulphate, nitrate). By regenerating the resins, typically with acids or alkalis, the system can operate efficiently over a long period of time.

Advantages of ion exchange technology

Selective and efficient removal of poorly degradable compounds: Ion exchangers are particularly efficient at removing poorly degradable compounds that are difficult or impossible to eliminate in conventional treatment processes. These include, for example, heavy metals, nitrate, ammonium and organic micropollutants.

Removal of trace substances and germs: Ion exchangers can remove even very low concentrations of impurities from water. This high selectivity and efficiency make the process particularly attractive for the pharmaceutical industry and food processing, where almost complete removal of germs and organic compounds is required.

Herstellung von hochreinem Prozesswasser: Mit der Ionenaustauschertechnologie kann hochreines Wasser mit einer extrem niedrigen Leitfähigkeit von < 0,055 µS/cm hergestellt werden. Dies ist besonders wichtig in der Elektronik- und Halbleiterindustrie, wo winzige Verunreinigungen die Funktionsfähigkeit der Produkte beeinträchtigen könnten.

Scalability and flexibility: Ion exchange systems have a modular design and can be flexibly adapted to the needs of the respective company. This makes them suitable for both smaller process flows and large-scale industrial applications.

Choosing the right technology depends on the water quality, the type of wastewater and the operational requirements. It is important to carry out a cost-benefit analysis to ensure that the technologies selected make both environmental and economic sense.

Planning the implementation

Once the technologies have been selected, the next step is to plan the implementation. A detailed implementation plan is crucial to ensure a smooth process and avoid delays. The plan should include the following:

- Schedule for the procurement, installation and commissioning of the water recycling systems.

- Budget planning including estimated costs for technology, installation and ongoing operation.

- Resource requirements such as technical equipment and qualified personnel.

- Responsibilities of the individual departments and employees.

In addition, staff training should be part of the implementation planning so that the water recycling system can be operated and monitored effectively. Good communication between departments ensures that everyone involved understands the plan and can implement it successfully.

Monitoring and optimization

Implementing a water recycling program is not the end of the process. Continuous monitoring is required to track the performance of the system and ensure that the defined goals are being met. A comprehensive monitoring system captures:

- Water consumption and wastewater volumes.

- quality of the recycled water to ensure that it meets the requirements for reuse.

- efficiency of the water treatment systems to determine whether further optimizations are possible.

Based on the monitoring data, optimization measures can be taken to further improve the efficiency of the system. Regular reviews and adjustments help to ensure the long-term sustainability and cost-effectiveness of the program.

Compliance with legal regulations and reporting

Compliance with legal regulations and environmental standards is an essential part of any water recycling program. Companies must ensure that their program complies with all relevant local, national and international laws. This includes the continuous monitoring of changes in legislation and the preparation of reports on water consumption and wastewater volumes.

A strong compliance program ensures that the company minimizes legal risks and at the same time contributes to a more sustainable use of water resources.

Raising awareness and involving stakeholders

The success of a water recycling program depends not only on technology and implementation, but also on acceptance and support within the company and beyond. Raising awareness among employees, customers and other stakeholders is critical to communicating the benefits of the program and raising awareness of sustainability.

Developing a communication strategy can help share the successes of the water recycling program and increase stakeholder engagement. This includes regular reports, workshops and information events on the environmental and economic benefits of the project.

Conclusion

The successful implementation of a water recycling program requires thoughtful planning and the use of the right technologies. From the initial analysis of water flows and selection of appropriate technologies to implementation and continuous optimization, a structured approach is critical to maximize efficiency and achieve sustainability goals. Stakeholder involvement and compliance with legal regulations are just as important as constant monitoring to ensure long-term success.

If you need help implementing a water recycling program, our team of experts is here to help. Get in touch with us!