Water is one of the most valuable resources on our planet and plays a crucial role in the economy. Companies in a wide range of industries need water for their production processes, which often leads to high consumption. In times when sustainability and resource efficiency are becoming increasingly important, the topic of water recycling is gaining in significance.

This blog article sheds light on why wastewater should be seen as a resource, what cost savings are possible through water recycling and also presents innovative technologies.

Table of contents

The critical role of wastewater as a resource

In the modern business world, wastewater is often mistakenly seen as a useless or even polluting substance. However, this perspective overlooks the immense potential that lies in the reuse and treatment of wastewater. Innovative recycling methods can help turn wastewater into a valuable resource that both reduces costs and promotes sustainability. Companies that recognize and implement this resource efficiency not only position themselves as leaders in environmental protection, but can also benefit significantly from reduced operating costs.

Potential for cost savings through water recycling

The financial benefits of water recycling are manifold. By treating and reusing wastewater internally, companies can significantly reduce their dependence on externally sourced water. This leads directly to lower water costs. In addition, the reduction in the volume of wastewater discharged into the public sewer system enables a reduction in wastewater charges. In addition to these direct cost savings, water recycling also contributes to more efficient production by ensuring a constant supply of process water, which in turn leads to an optimization of operational processes.

Advanced technologies for water recycling

The range of technologies available for recycling wastewater is broad and technologically advanced. Membrane filtration techniques, such as ultrafiltration or reverse osmosis, offer highly efficient solutions for separating pollutants from water, achieving a quality that allows it to be reused in industrial processes. Biological treatment processes utilize the natural ability of microorganisms to break down organic matter and are particularly effective in the treatment of municipal and industrial wastewater. Advanced Oxidation Processes (AOPs) represent a group of chemical treatment processes that are capable of effectively removing even stubborn contaminants through the generation of strong oxidizing agents.

Processes and technologies

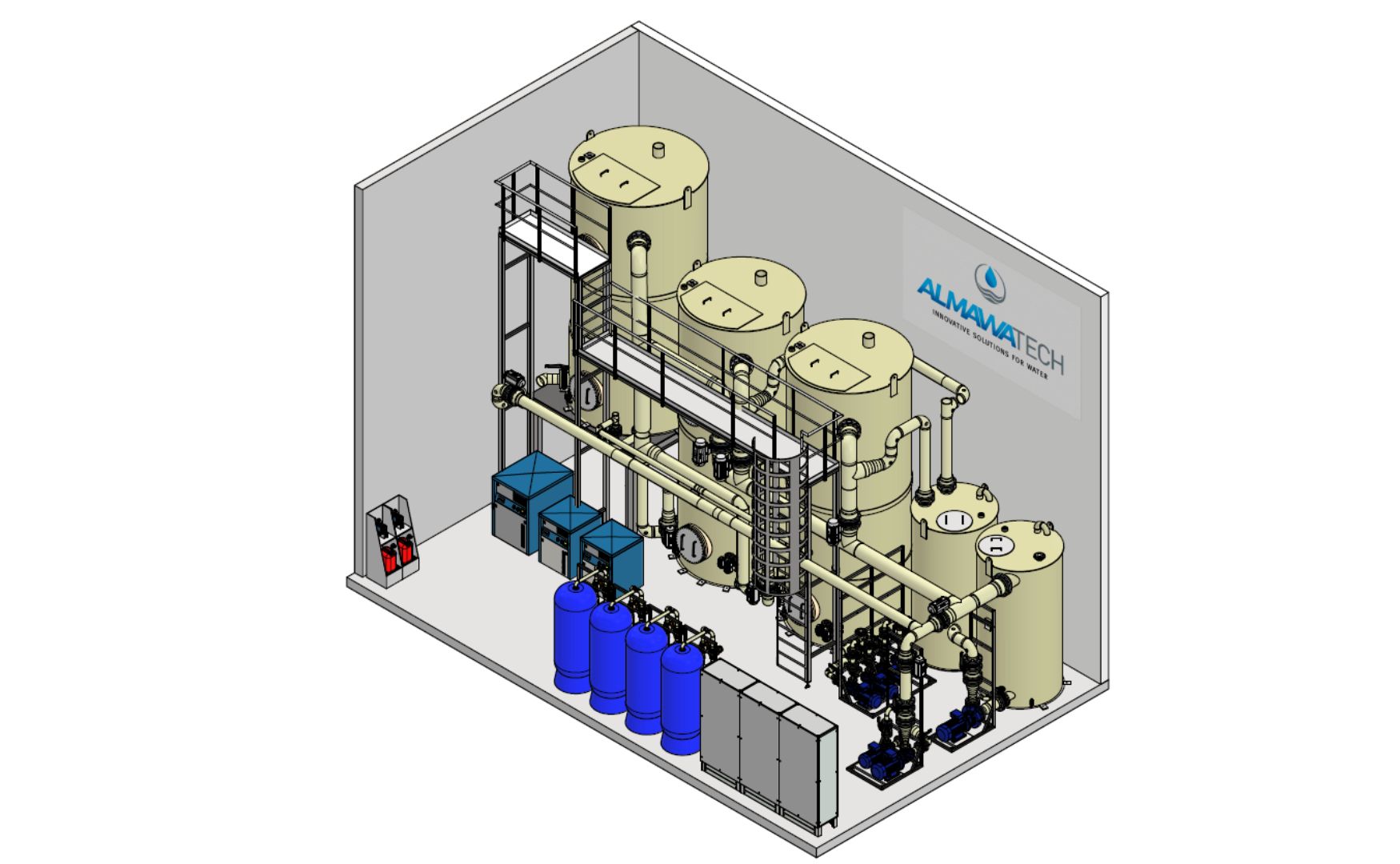

Membrane filtration & reverse osmosis

Photo: ALMA OSMO Process (to the product)

Area of application:

Ideal for the removal of undissolved substances, dissolved impurities and trace substances from wastewater and process water. Frequently used in industries that require high water quality, such as the food and beverage industry or the pharmaceutical industry.

Advantages:

- High cleaning performance with the ability to produce ultrapure water.

- Compact design and modular systems that are easily scalable.

Biological pre-treatment

Photo: ALMA BioFil Compact (to the product)

Area of application:

Particularly suitable for wastewater with a high organic content. Often used in municipal wastewater treatment plants and in industries such as agriculture and food processing. In addition, biological treatment systems such as the ALMA BioFil Compact are often implemented as pre-treatment for membrane filtration systems. This reduces the occurrence of biofouling and thus extends the service life of the membrane.

Advantages:

- Effective reduction of organic pollutants through natural processes.

- Lower operating costs compared to other advanced technologies.

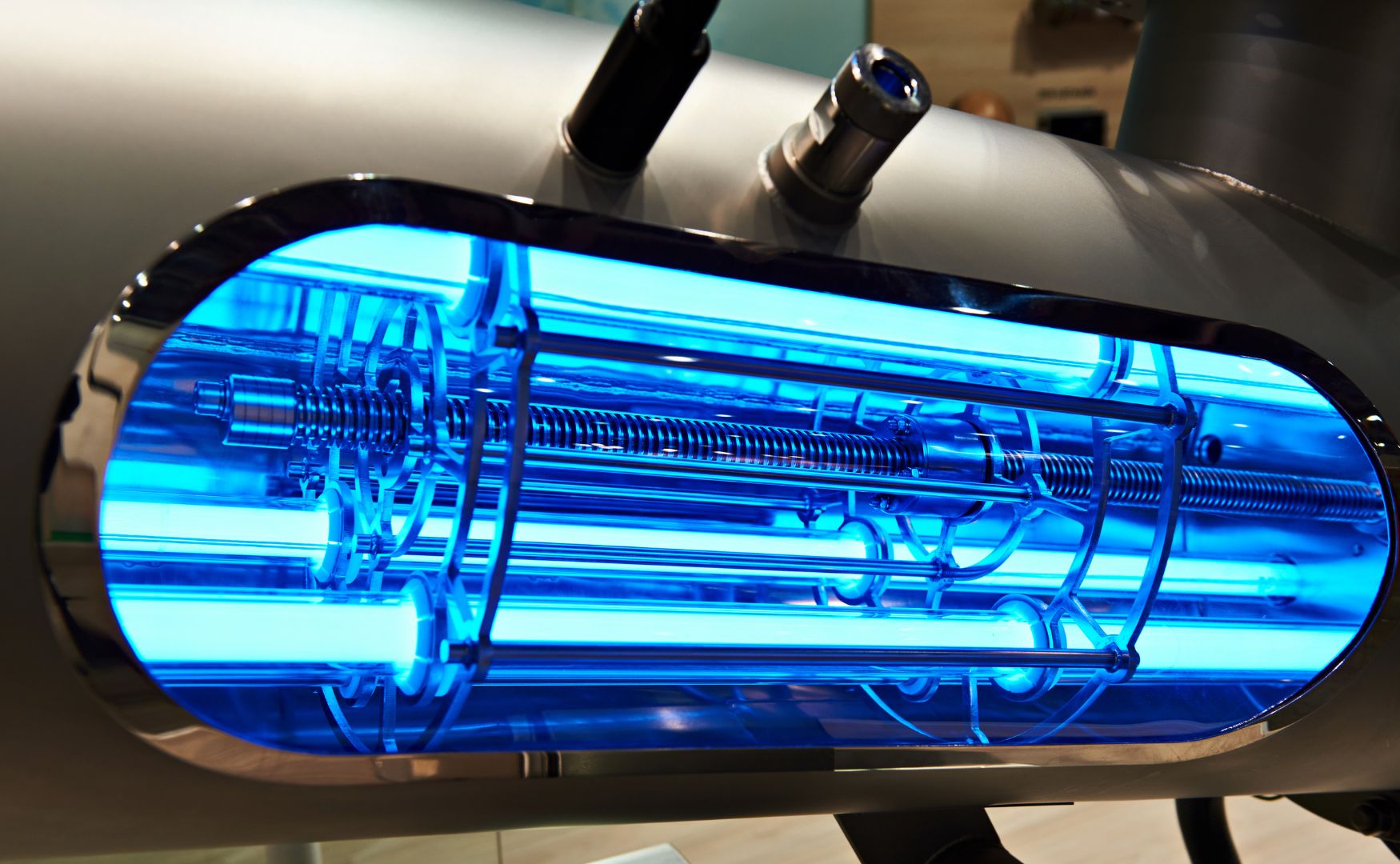

Advanced Oxidation Processes (AOPs) e.g: UV oxidation and Fenton process

Photo: ALMA OXI UV (to the product)

Area of application:

Ideal for the treatment of wastewater containing poorly degradable compounds, trace substances and germs. Frequently used in the production of high-purity process water for the chip industry, hydrogen production and the pharmaceutical industry.

Advantages:

- Highly effective in the destruction of persistent organic pollutants and micropollutants.

- Ability to significantly improve water quality and make it reusable for demanding applications.

Selective ion exchangers

Photo: ALMA ION (to the product)

Area of application:

Ion exchange systems are ideal for a range of applications due to their ability to remove complex impurities and micropollutants from water. This technology is often used in the production of high purity process water required for the sensitive production processes in the electronics, solar and pharmaceutical industries. The use of ion exchangers enables these industries to meet the strict quality requirements for process water.

Advantages:

- Selective and efficient removal of poorly degradable compounds, trace substances and germs from wastewater.

- Herstellung von hochreinem Prozesswasser mit einer Leitfähigkeit von < 0,1 µS/cm möglich.

Selection criteria

When selecting the appropriate technology for water recycling in a company, several factors must be taken into account:

Type and composition of the wastewater:

Determines which pollutants need to be removed and which technology is most effective.

Desired water quality:

Depending on the planned reuse of the treated water. Reuse in cooling circuits, boilers and hot water networks as well as use as process or cleaning water is possible.

Costs:

Both investment and operating costs are important considerations.

Available space:

Where space is limited, a modular container design is preferable.

Environmental requirements:

Compliance with local regulations and standards may require certain technologies.

By carefully weighing up these criteria, companies can select the most suitable water recycling technology for their specific needs and objectives.

Conclusion

Developing a comprehensive water recycling plan is a complex but rewarding process. Through systematic planning and implementation, companies can not only reduce their environmental impact and contribute to the sustainable use of water resources, but also reduce their operating costs and strengthen their market position.

With the right approach and commitment, water recycling can make a significant contribution to the long-term success and sustainability of your company.

If you need help with water recycling, we will be happy to advise you! Simply contact us!