UASB reactor (Upflow Anaerobic Sludge Blanket reactor) is an anaerobic reactor system for the treatment of organically contaminated wastewater, which is widely used in industrial water and wastewater treatment. The UASB react or is specifically designed to break down dissolved organic matter in wastewater through the use of anaerobic microorganisms and convert it into biogas (mainly methane and carbon dioxide). This technology is particularly effective for the treatment of wastewater with a high organic load and offers the possibility of generating energy by using the biogas produced.

Table of contents

Technical basics of the UASB reactor

A UASB reactor is a reactor for anaerobic wastewater treatment in which the wastewater flows from bottom to top through a sludge blanket containing a high density of anaerobic microorganisms. The microorganisms decompose the organic substances in the absence of oxygen and produce biogas in the process. The UASB reactor uses a natural sedimentation layer of microbial aggregates that forms at the bottom of the reactor and supports the growth of anaerobic bacteria.

Structure of a UASB reactor

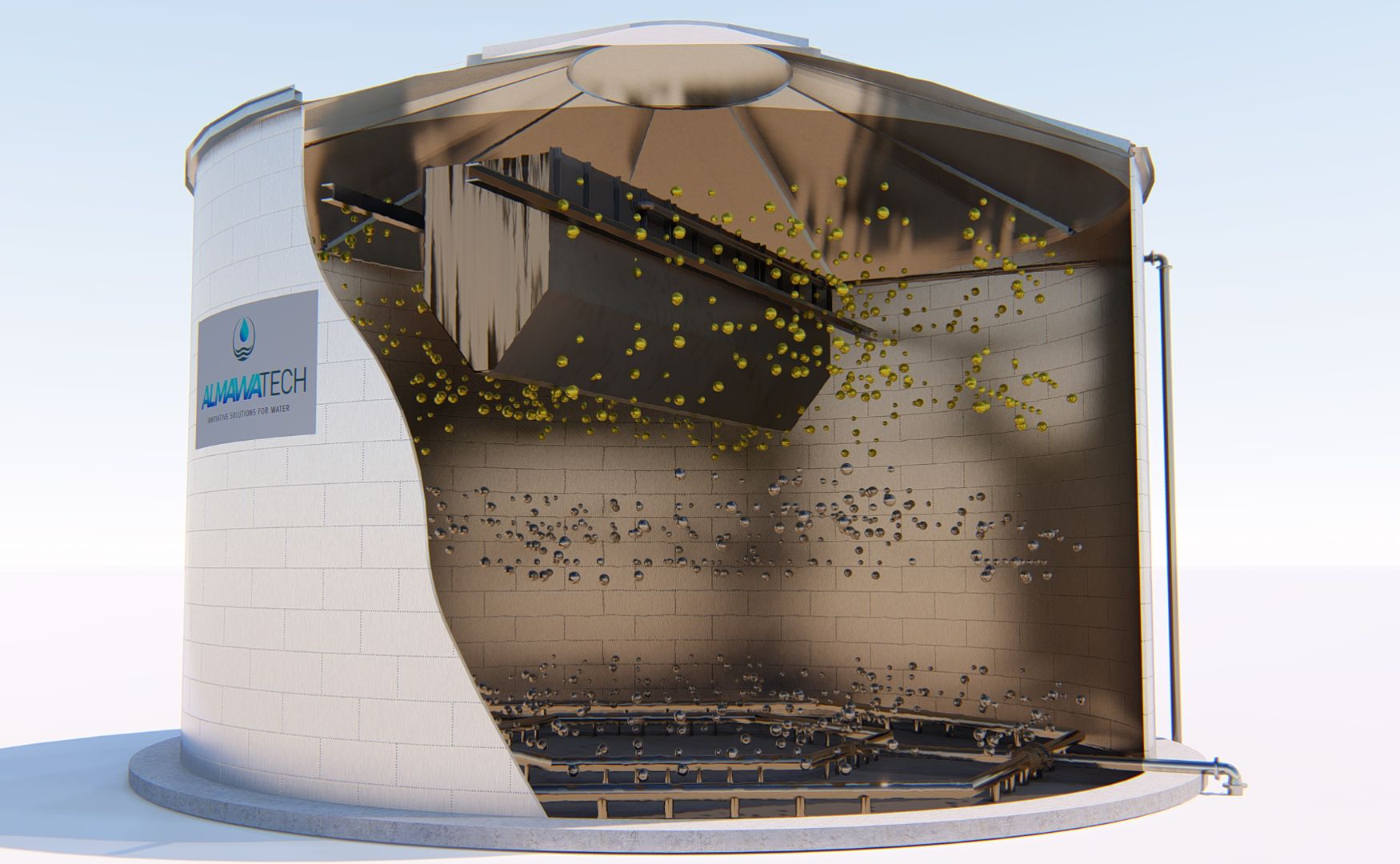

A typical UASB reactor consists of the following components:

Inlet and distribution system:

- The waste water is introduced through a specially developed inlet system at the bottom of the reactor, which ensures even distribution of the waste water. This ensures optimum contact between the microorganisms and the wastewater.

Mud blanket (Sludge Blanket):

- This sludge layer is the heart of the UASB reactor and consists of anaerobic microorganisms that break down organic substances in the wastewater and convert them into biogas. The sludge is organized in the form of granulate-like particles that exhibit high biological activity and sedimentation stability.

Three-phase separator (Three-Phase Separator):

- The three-phase separator separates the biogas produced, the purified water and the sludge. This separator ensures that the biogas can escape from the water and the treated water is discharged via the overflow. The sludge is retained in the reactor and recirculated.

Gas collection system:

- The biogas is collected in the upper section of the reactor and can then be used as an energy source or stored.

Photo: Schematic representation of our ALMA BIO UASB reactor

How the UASB reactor works

The UASB reactor works according to the principle of upward flow. The wastewater flows from the bottom upwards through the sludge blanket in which the anaerobic microorganisms are located. These microorganisms use the organic substances in the wastewater as food and break them down to produce biogas. The biogas, which consists mainly of methane, rises to the top and is collected by a special collection system. The purified water also flows upwards and leaves the reactor via the overflow.

Anaerobic microbiology in the UASB reactor is based on a consortial approach in which various microorganisms work together symbiotically to gradually break down the organic substances. In the various degradation phases (hydrolysis, fermentation, acetogenesis and methanogenesis), the organic material is gradually converted into methane and carbon dioxide.

Technical advantages of the UASB reactor

High degradation performance with organic load:

- The UASB reactor can effectively break down high concentrations of organic substances and is therefore particularly suitable for wastewater from the food and beverage industry, the paper industry and the pharmaceutical industry.

Low energy consumption:

- As the UASB reactor works without aeration, its energy consumption is significantly lower compared to aerobic processes. This leads to cost savings and lower CO₂ emissions.

Biogas production and energy recovery:

- The UASB reactor produces biogas as a by-product, which can be used as a renewable energy source. This contributes to the energy efficiency of the process and can reduce operating costs.

Compact design:

- The vertical design of the UASB reactor saves space and can also be installed where space is limited.

Robustness and flexibility:

- The UASB reactor is adaptable and can quickly adjust to fluctuations in the organic load and temperature of the wastewater, making it versatile and robust.

Photo: ALMA BIO UASB for the production of biogas from waste water from the sugar industry

Areas of application of the UASB reactor

The UASB reactor is ideal for the treatment of heavily contaminated industrial wastewater and is therefore widely used in the following industries:

Food and beverage industry:

- Waste water from food production often contains high concentrations of sugar, fats and proteins. This wastewater is an ideal source of nutrients for the anaerobic microorganisms in the UASB reactor.

Paper and pulp industry:

- Paper production produces wastewater with a high organic load, which can be treated efficiently by the UASB reactor. Anaerobic degradation can significantly reduce the COD (chemical oxygen demand).

pharmaceutical and chemical industry:

- The wastewater from these industries contains complex organic compounds that are difficult to break down using aerobic processes. The UASB reactor offers an energy-efficient and cost-effective solution for wastewater treatment.

Whey processing and dairies:

- Dairies produce wastewater that is rich in organic matter and fats. The UASB reactor can break down these substances and produce biogas, making it an environmentally friendly and economical solution for the dairy industry.

Challenges and maintenance of the UASB reactor

Sludge management: The sludge in the UASB reactor must be checked regularly to keep the microorganisms at the optimum concentration. Too high a sludge concentration can lead to blockages and loss of performance.

Biofouling and sedimentation: Sedimentation and buildup in the sludge pad can affect flow and efficiency, so regular cleaning and maintenance is required to ensure optimal performance.

Temperature sensitivity: The anaerobic degradation process is sensitive to temperature and deviations from the optimum operating temperature can affect the efficiency of the microorganisms. At lower temperatures, the rate of degradation may slow down.

Photo: ALMA BIO UASB biogas plant

Comparison with the EGSB reactor

The UASB react or differs from the EGSB reactor (Expanded Granular Sludge Bed) in terms of flow rate and sludge behavior. While the EGSB reactor uses a higher flow rate and an expanded sludge bed, the UASB react or works with a more stable, sedimenting sludge bed and a slower flow. The UASB reactor is particularly suitable for wastewater with medium to high COD, while the EGSB achieves higher degradation rates with heavily contaminated wastewater.

Conclusion

The UASB reactor is a proven and efficient technology for the anaerobic treatment of organically contaminated wastewater that combines biogas production and wastewater treatment. It is energy-efficient, cost-saving and offers stable performance with different wastewater loads. In wastewater treatment, the UASB reactor is a sustainable and economical solution that is particularly suitable for industries with high levels of organic wastewater. Its simple design and low maintenance requirements make it a valuable addition to many industrial water treatment systems.

For further information on our products, please feel free to contact us at any time!