A pinch valve (also known as a hose pinch valve ) is a special valve used in many industries, including process water and wastewater treatment. process water and wastewater treatmenttreatment. It is characterized by its simple design, high reliability and excellent resistance to abrasive and corrosive media. The operating principle is based on the mechanical squeezing of a flexible hose or sleeve, which controls the flow of the medium.

Table of contents

Technical background of the pinch valve

1. structure and components

A typical pinch valve consists of the following main components:

Housing:

- Can be made of metal (e.g. stainless steel, aluminum) or plastic (e.g. PVC, PP).

- Protects the internal cuff and ensures mechanical stability.

Cuff/tube:

- Flexible component that comes into direct contact with the medium.

- Materials: Elastomers such as natural rubber (NR), EPDM, nitrile (NBR) or silicone. These depend on the chemical resistance and temperature requirements of the medium.

Actuation system:

- Manual: Via handwheels or levers.

- Pneumatic: Use of compressed air to actuate the squeeze mechanism.

- Hydraulic: Use of fluid pressure for control.

- Electric: Electric motors that move the squeeze mechanism.

2. mode of operation

The pinch valve controls the flow by squeezing the flexible sleeve. It is actuated by:

- Pneumatic pressure:

- Compressed air is applied to the outer shell of the sleeve, causing it to shut off the flow.

- Mechanical pressure:

- An external mechanism compresses the cuff to block the flow.

- Springback:

- When the pressure is released, the cuff opens automatically as it returns elastically to its original shape.

3. types of pinch valves

- Single-seat pinch valves:

- Cuff is squeezed at one point.

- Suitable for applications with low flow regulation.

- Two-seat pinch valves:

- The cuff is crimped at two points to ensure complete closure.

- Ideal for abrasive or highly viscous media.

Photo: Our gravel and multi-layer filters (ALMA Fil) with pneumatically operated pinch valves

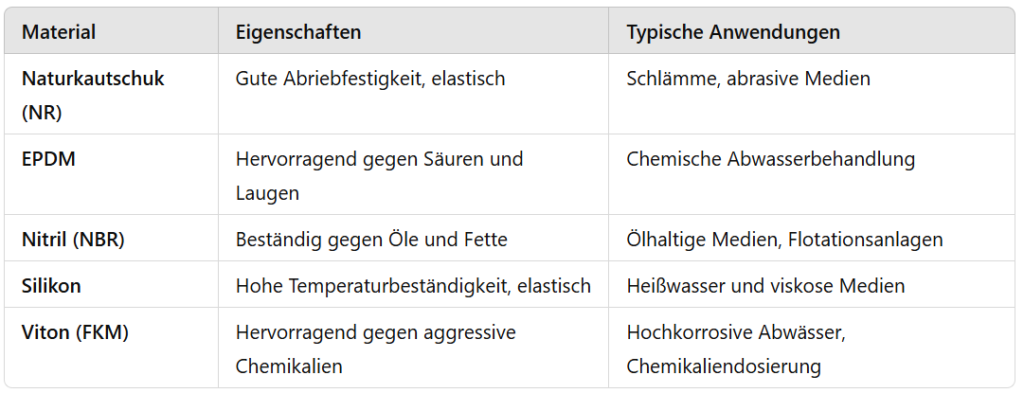

Cuff materials and their selection

The choice of sleeve is crucial for the durability and functionality of the pinch valve. The selection is based on the medium, the temperature and the chemical load:

Advantages and challenges

Advantages

- Durability: The flexible cuff minimizes wear and tear.

- Versatility: Can be adapted for almost all types of media.

- Low pressure loss: When open, the cuff enables an almost laminar flow.

- Easy integration: compact design and simple installation.

Challenges

- Pressure limitation:

- Not suitable for high-pressure applications (>16 bar).

- Temperature limitation:

- Depending on the material of the sleeve (max. 150 °C for special rubber).

- Replacing the cuff:

- Regular replacement of the sleeve required for very abrasive applications.

Conclusion

The pinch valve is an indispensable component in process water and wastewater treatment. Its simple design, robustness and versatility make it particularly suitable for abrasive, corrosive and particulate media. With the right choice of material and regular maintenance, the efficiency and service life of the valve can be maximized. Pinch valves are therefore an economical and reliable solution for demanding applications in water technology.

For further information on our products, please feel free to contact us at any time!