A growth carrier is a solid substrate or material that serves as a colonization surface for microorganisms in biological water and wastewater treatment processes. Growth media are mainly used in biofilm-based reactor systems, such as trickling filters, fixed bed reactors, fluidized bed reactors or membrane bioreactors (MBR). They provide microorganisms with the necessary surface area to colonize in the form of biofilms and break down organic impurities in the water. The choice and design of the growth carriers directly influence the efficiency of the biological treatment, as they increase the surface area and optimize the activity of the microorganisms.

Table of contents

Technical background and types of growing media

Growing media are manufactured from various materials that are corrosion-resistant, chemically stable and structurally suitable for long-term operation in water-bearing systems. Common materials include

Plastics: Polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and similar thermoplastics are widely used due to their durability and low density. They offer a high specific surface area for the growth of microorganisms and are also resistant to the chemicals frequently used in wastewater treatment plants.

Ceramic: Ceramic growth media are often used in applications where particularly high chemical stability or temperature resistance is required. Their porous structure provides a large surface area and supports the formation of thicker biofilms.

Natural materials: In older or special systems, natural materials such as lava stone or porous stones can also be used. These also have a rough surface that offers microorganisms opportunities to adhere.

The design of the growth carriers significantly influences the efficiency of biofilm formation. There are various designs that are tailored to specific applications:

Fixed-bed carrier: In fixed-bed reactors (e.g. trickling filters), the growth carriers are arranged statically in a reactor bed. The wastewater flows over or through the bed, allowing microorganisms to colonize the surface and carry out biological degradation.

Moving carriers: In fluidized bed react ors, growth carriers are mixed in the water flow and kept in motion. This type of growth media offers a larger surface area per unit volume and enables a continuous supply of oxygen to the microorganisms, which accelerates the degradation process.

Structured carrier materials: Growth carriers can have various geometric shapes to maximize the specific surface area. These include rings, tubes and honeycomb structures, which increase the colonization area for biofilms and improve the flow of liquid.

Areas of application for growing media

Growth media are used in a variety of biological reactors, particularly in biological wastewater treatment and water treatment. The most common applications include

Trickling filter: In trickling filter systems (also known as percolation systems), the wastewater flows over a fixed bed filled with growth media. The microorganisms colonized on the carriers break down the organic substances in the wastewater as it percolates through the trickling filter. This process is often used to treat municipal wastewater and is particularly suitable for wastewater with a medium to high organic load.

Fixed bed reactors: In fixed-bed reactors, the growth carriers are arranged stationary in a reactor bed through which the wastewater is passed. These reactors are often used in industry for the treatment of process water or heavily contaminated wastewater. They offer the advantage of a high biomass concentration and controlled water flow.

Fluidized bed reactors: In fluidized bed reactors, the growth carriers are in a fluid flow that keeps them in motion. This configuration provides continuous aeration of the microorganisms and prevents the reactor from clogging. Fluidized bed reactors are often used in industrial wastewater treatment, particularly for nitrogen removal (denitrification) or the treatment of wastewater with a high organic load.

Membrane bioreactors (MBR): In MBR plants, the combination of growth media and membrane filtration is used to both break down organic matter and ensure a clear separation of biomass and purified water. Here, the growth carriers ensure high microbiological activity, while the membranes guarantee solids retention.

Photo: Compact membrane bioreactor in modular design(ALMA BIO MBR)

5. biofiltration systems

ALMA BHU BAF and ALMA BioFil Compact are innovative biofiltration systems from ALMAWATECH that use specially developed clay beads as growth carriers. These clay beads are characterized by a high specific surface area, which provides a habitat for both aerobic and anoxic microorganisms. These systems are particularly suitable for removing residual organic pollutants and nutrients from water streams, thus ensuring high purification performance.

a) ALMA BHU BAF (Biologically Activated Filtration):

- In this system, the specially prepared clay beads provide the microorganisms with a stable environment for biofilm formation. The system promotes simultaneous aerobic and anoxic biological activity, enabling effective nutrient removal (especially nitrogen and phosphorus) and the decomposition of organic matter. The continuous flow of water through the clay beads prevents clogging and supports efficient flow, allowing the system to work reliably even with high water loads.

- Find out more about our biologically activated filtration for water flows of up to 1,000 m³/h: ALMA BHU BAF

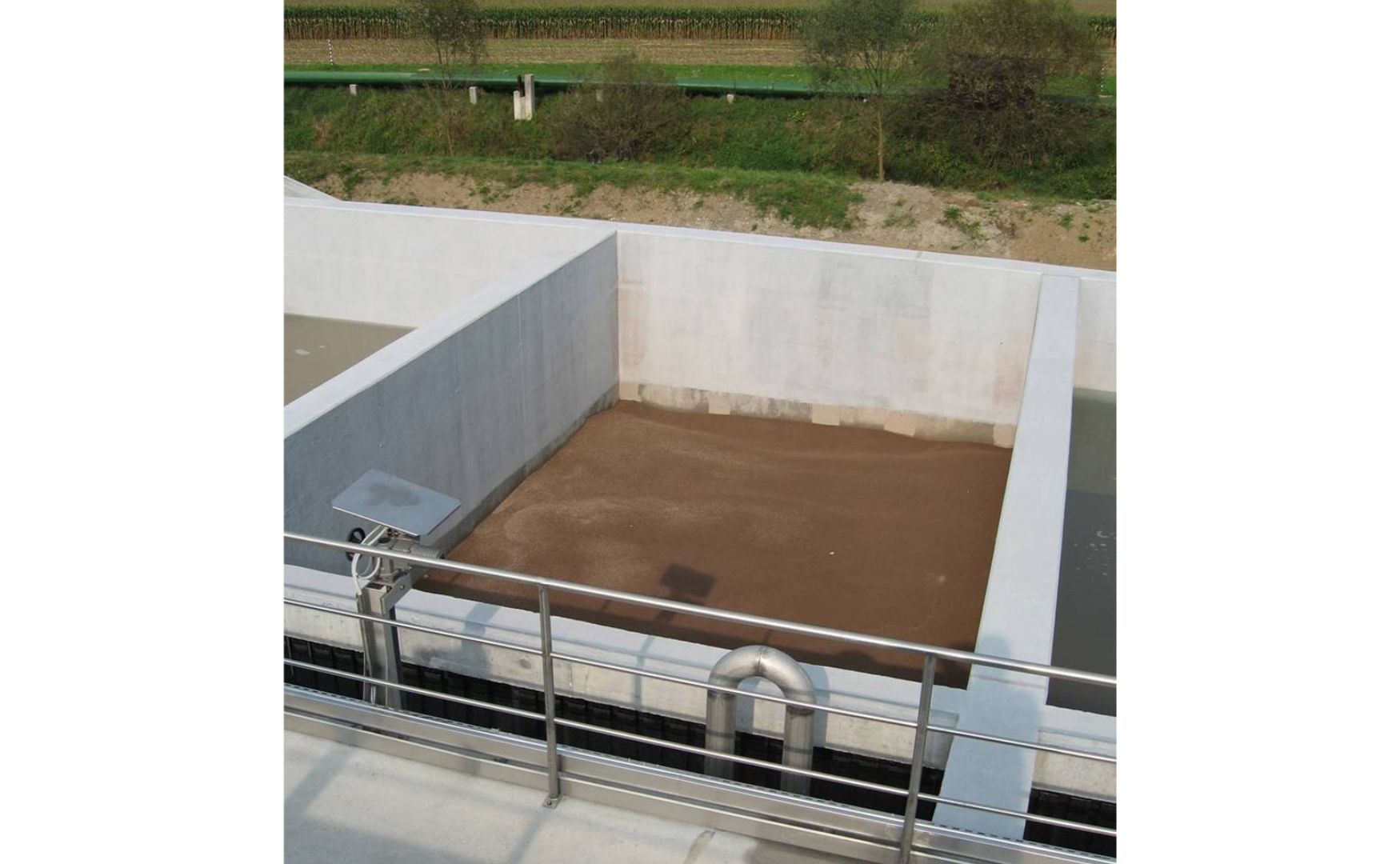

Photo: Empty reaction tank from our ALMA BHU BAF process in which the growth bodies (clay beads) can be seen

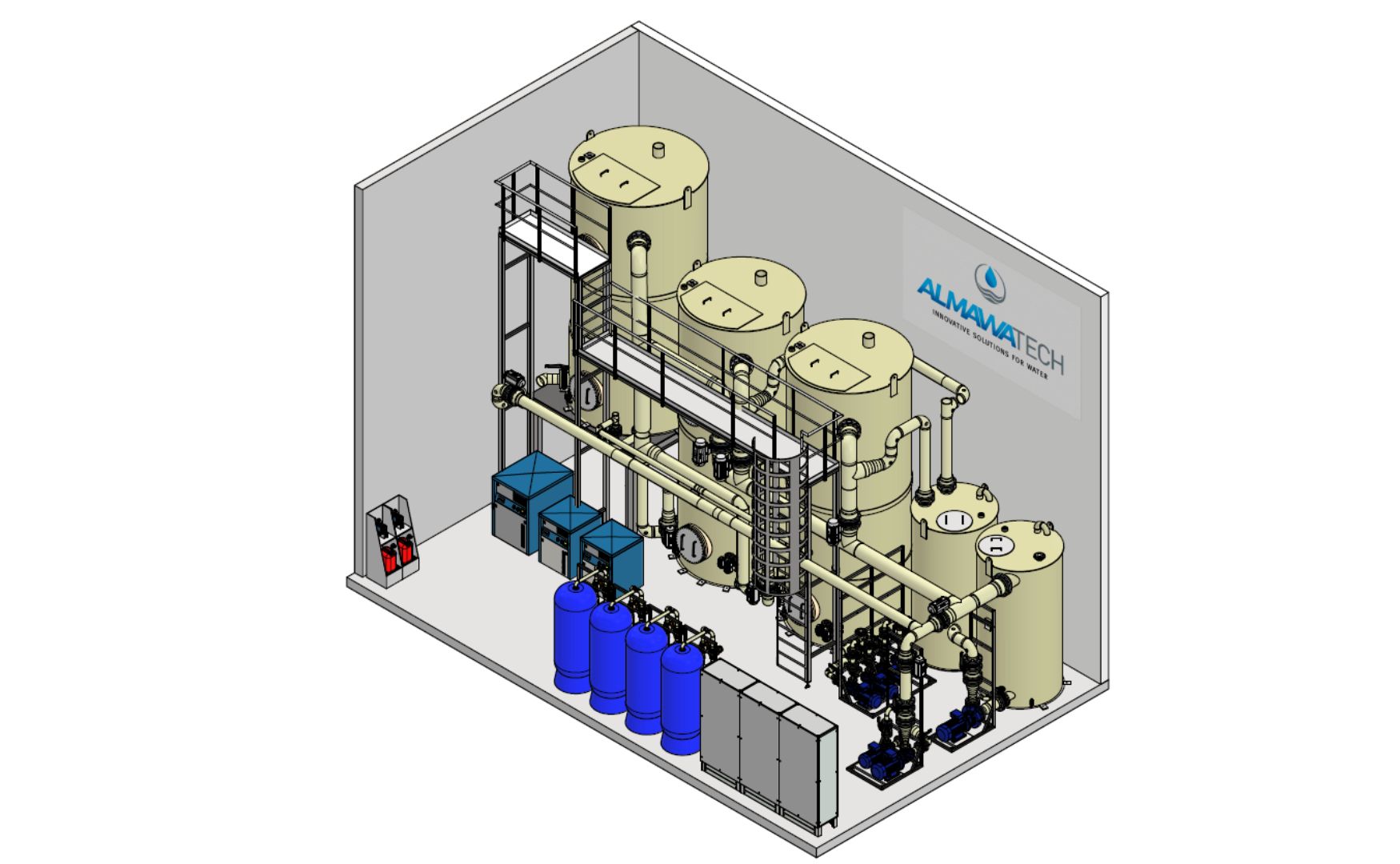

b) ALMA BioFil Compact

- This compact system is specially designed for smaller wastewater flows of up to 50 m³/h and also uses the highly developed clay beads as a growth carrier. It is particularly suitable as a pre-treatment step for reverse osmosis systems, as it reduces biofouling by efficiently removing residual organic matter and nutrients. This helps to extend the service life of the membranes and improve the operational stability of the downstream systems.

- Find out more about our compact biofiltration: ALMA BioFil Compact

The clay beads in these systems enable intensive microbiological colonization as they offer a three-dimensional structure with numerous pores and cavities. This structure supports both aerobic processes for the removal of organic matter and anoxic processes, which are important for denitrification. As a result, comprehensive biological purification is achieved, which is relevant for many industrial applications, including the food industry, dairies and other water-intensive industries.

Photo: 3D design of our ALMA BioFil Compact system

Advantages and challenges

Advantages:

Increased specific surface area: Growth media offer the microorganisms an increased colonization area compared to suspension systems such as the activated sludge process. As a result, a larger biomass can be colonized in the reactor, which leads to more efficient biodegradation.

More stable processes: As the microorganisms adhere firmly to the growth media, these systems are more stable against fluctuations in the load of the wastewater or in the hydraulics of the system. Biofilm-based systems are often more resistant to toxic substances or sudden load peaks in the wastewater.

Compact plant design: By using growth carriers, the volume of the reactors can be kept smaller, as a higher biomass concentration per unit volume is achieved. This is particularly advantageous in applications where space is limited, e.g. when modernizing existing plants.

Challenges:

Biofilm growth and clogging: If the biofilm on the growth media becomes too thick, this can lead to clogging and restricted fluid circulation. Regular maintenance and cleaning of the growth media is therefore necessary to ensure the functionality of the system.

Sludge discharge: In some reactors, biomass may be removed (sludge discharge), especially if the load on the system is too high or the hydraulic conditions are not optimal. This can impair the cleaning performance and requires an adjustment of the operating parameters.

Practical examples and relevance

Growth media are used in many industrial applications, particularly in the treatment of highly contaminated wastewater, such as that found in the food industry, the pulp and paper industry and the chemical industry. One particular example is the use of growth media in denitrification and nitrification, where they contribute to the removal of nitrogen compounds from wastewater streams.

ALMAWATECH offers special biological systems based on the use of growth media, such as the ALMA BHU BioFil series. These bioactivated filtration systems use growth media to efficiently reduce residual organic loads in large water streams, which supports pretreatment for reverse osmosis systems (product overview reverse osmosis systems) and other recycling processes. The use of growth carriers helps to minimize biofouling and improve water quality, resulting in a more stable and economical operation in the long term.

Conclusion

Growth media are an essential element in biofilm-based reactors and play a central role in biological wastewater and water treatment. They enable efficient colonization by microorganisms and contribute to the stability and performance of biological systems. Thanks to their versatile design and choice of materials, they can be adapted to a wide range of industrial requirements. They are becoming increasingly important in areas where high purification performance is required in a limited space.