Filter cake refers to the solid residue mass produced during the mechanical filtration and dewatering of sludge, particularly in processes such as the chamber filter press or other pressure filtration technologies. The filter cake consists of the retained solids and is the end product of the filtration process in which the filtrate (the purified water or a solution) is discharged from the filter medium. In industrial wastewater and sludge treatment, the filter cake is an important element as it may contain valuable or pollutant-containing residues that need to be disposed of or processed in an environmentally safe manner.

Table of contents

Formation and composition of the filter cake

The filter cake is formed when the sludge to be treated is pressed through a filter medium, such as filter cloths or membranes, and the solids are retained by the pores of the medium. The composition of the filter cake depends heavily on the properties of the material supplied, such as the particle size, chemical structure and concentration of the solids.

The most important factors influencing the formation and composition of the filter cake are

Particle size and distribution:

- Fine particles often form a denser and less porous cake, which can make dewatering more difficult. Coarser particles, on the other hand, enable better dewatering as they create a more open structure in the filter cake.

Solids concentration in the sludge:

- High solids concentrations lead to faster formation of a thicker filter cake, which increases filtration efficiency, while low concentrations can extend the process time.

Conditioning of the sludge:

- The sludge is often conditioned before filtration by adding flocculants or precipitants to increase the particle size and improve dewaterability.

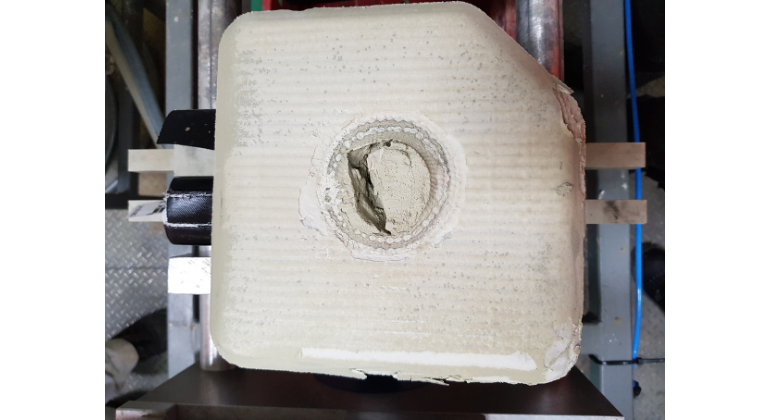

Photo: Photo of a filter cake from one of our test chamber filter presses

Technical processes for filter cake formation

The formation of the filter cake is a multi-stage process that can vary depending on the respective systems:

Filling and pressure build-up:

- The sludge is pressed into the filter chambers under high pressure. The increasing pressure forces the water through the filter medium, leaving the solids behind as filter cake.

Cake structure and filtration cycle:

- As filtration progresses, the filter cake becomes more dense as additional solids are deposited on top of the existing layer. The pressure is maintained to minimize the pores between the particles and reduce the moisture content.

Drainage and unloading:

- Once the filtration cycle is complete, the hydraulic pressure in the filter press is reduced, the plates are separated and the filter cake is discharged from the chambers.

Degree of dewatering and moisture content of the filter cake

The degree of dewatering of the filter cake is a decisive criterion, as it determines the dry substance concentration (DS), i.e. the proportion of solids in the cake. A higher dry matter concentration reduces the volume and lowers the transportation and disposal costs.

- Dry filter cake: Achieved at high filtration pressures and has a DS of 40-60%, which is typical for many industrial applications.

- Wet filter cake: Occurs at low pressure or less effective filtration and contains more moisture, which can make disposal and further treatment more difficult.

Photo: ALMA CFP chamber filter press for dewatering sludge from CP systems

Influence of the filter cake on the filtration efficiency

A well-drained filter cake offers several advantages:

Reduction in operating costs:

- A dry filter cake has less water content and therefore a smaller volume, which reduces transportation and disposal costs.

Improved filtration performance:

- The correct adjustment of the filter cloths and the pre-treatment of the sludge help to ensure that the filter cake dissolves more easily and the next filtration round can be started without residue.

Facilitation of the filtering process:

- An efficiently detached filter cake that does not stick to the filter medium reduces the cleaning requirements and increases the filtration cycle times.

Applications and disposal of the filter cake

In practice, the filter cake can either be disposed of or, if it contains valuable substances, processed further. Examples of disposal and use are

Landfill:

- If the filter cake contains contaminated or hazardous substances, it must be disposed of safely in accordance with legal requirements, often at designated landfill sites.

Recycling of recyclable materials:

- In metal processing and electroplating, the filter cake often contains heavy metals that can be recovered by further processes.

Composting or agricultural use:

- Filter cakes from the food and agricultural industries that are harmless can be composted or used as fertilizer.

Photo: Our ALMA CFP chamber filter press installed in the ALMA Modul technical room container

Optimization of the filter cake - pilot tests and consulting

To ensure optimum sludge dewatering, we offer pilot tests that enable a comprehensive analysis of the filter cake.

These tests can be carried out either on your premises or in our technical center. We test the filterability and dewaterability of the sludge and adjust the selection of filter cloths and filtration parameters to produce a filter cake that separates easily from the cloths and has a high dry substance concentration. With our precipitation and flocculation plant, we can also carry out preliminary tests to ensure the best possible conditioning of the sludge.

Conclusion

The filter cake is a key product of mechanical filtration and dewatering in industrial water and wastewater treatment. Its composition and the efficiency of its dewatering are decisive factors for the economic efficiency and sustainability of the entire wastewater treatment process. A well-dewatered filter cake saves disposal costs, facilitates handling and can serve as a source of recyclable material in certain cases. Targeted process optimization and the right choice of filter cloths and operating materials can significantly increase the efficiency of filter cake formation and the cost-effectiveness of the entire sludge dewatering process.

For further information on our products, please feel free to contact us at any time!