The filter chamber is a central component of dewatering units and filter presses that are used in industrial water and wastewater treatment to separate solids and liquids. Together with the filter plates and filter cloths, the filter chamber forms the heart of the filtration processes and enables the efficient separation of solids through targeted pressure filtration. Typical applications for filter chambers include sludge treatment in sewage treatment plants, the dewatering of highly contaminated industrial wastewater and the separation of solids in chemical and pharmaceutical production processes.

Table of contents

Structure and function of a filter chamber

The filter chamber is located between the individual filter plates in a filter press and consists of an enclosed space into which the sludge to be filtered is filled under high pressure. It is closed by filter cloths or membranes, which keep the pores open for the filtrate to pass through and at the same time prevent solids from penetrating.

Filter plates: These form the structural basis of the filter chambers and are arranged in rows. Each filter plate is covered with a filter cloth that retains the solids on the inside of the chamber.

Filter cloths: These filter media are crucial for filtration efficiency. They are usually made of chemically resistant materials such as polypropylene or polyester and are matched to the particle size and chemical composition of the sludge to be filtered.

Filtration process in the filter chamber

Filling the chamber:

- The sludge to be treated is pumped into the chamber under high pressure. The filter cloths allow the water and smaller dissolved substances to pass through their pores, while the solids are retained and deposited on the surface of the filter cloth as filter cake.

Pressure build-up and drainage:

- The hydraulic pressure is continuously increased to further reduce the water content and compact the filter cake. This leads to a significant reduction in the water content and enables a dry substance concentration in the filter cake.

Drain the filtrate:

- The water filtered through the filter cloth, the so-called filtrate, is discharged via a drainage system. It can either be processed for further treatment or returned to the production cycle, depending on the requirements of the process.

Removal of the filter cake:

- At the end of the filtration cycle, the pressure is released and the filter plates are separated so that the filter cake falls out of the chamber and can be collected for disposal or further processing.

Photo: ALMA CFP chamber filter press for dewatering sludge from CP systems

Types and application areas of filter chambers

- In this application, the filter cake is kept in a solid state on the filter cloth until the cycle is complete. It is often used in municipal wastewater treatment to dewater sewage sludge and reduce the volume of the sludge.

2. membrane filter press:

- After filtration, the filter cake is additionally compressed by flexible membranes that exert additional pressure. This type of filter chamber is mainly used for very moist sludges that require a high dry substance concentration.

3. flatbed chambers:

- These chambers are suitable for continuous filtration of small volumes and fine particles and are often used in the chemical and pharmaceutical industries where precise separation is important.

4. vacuum chambers:

- In vacuum filtration chambers, a vacuum is generated which draws the filtrate through the filter medium. This type of chamber is often used for applications where liquids and solids need to be separated more quickly.

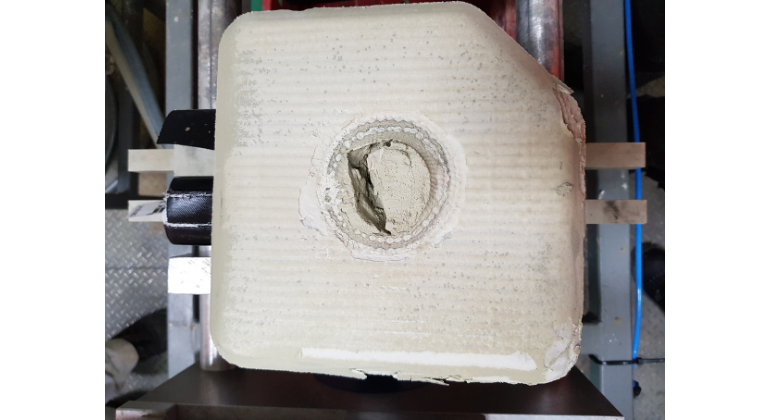

Photo: Photo of a dewatered filter sludge from one of our test chamber filter presses

Pilot tests with your wastewater

To ensure that the chamber filter press is optimally designed for your specific requirements, we offer pilot tests that we can carry out either directly on your premises or in our technical center.

In these tests, we analyze the filterability and degree of dewatering of your wastewater and determine the most suitable filter cloth to ensure optimum detachment of the filter cake and prevent the filter cake from sticking to the filter cloth. We use our precipitation and flocculation plant (CP system) to produce a dewaterable sludge in advance, which is then dewatered in our chamber filter press. This approach enables us to determine the best configuration for your specific application and to design the dewatering process efficiently.

Photo: Our ALMA CFP chamber filter press installed in the ALMA Modul technical room container

Technical advantages of the chamber filter press

High solids concentration:

- Chamber filter presses produce a very dry filter cake, which significantly reduces transportation and disposal costs.

Easy handling and automation:

- Many filter press models offer a high degree of automation, which simplifies operation and shortens cycle times.

Efficient filtration with high solids content:

- They are particularly suitable for applications with high solids concentrations and enable effective separation even with challenging wastewater compositions.

Flexible application options:

- Chamber filter presses can be customized according to requirements and wastewater composition, making them versatile and efficient in a wide range of industries.

Challenges when using chamber filter presses

Maintenance and cleaning of the filter cloths:

- The filter cloths can become clogged with fine particles and must be cleaned regularly to ensure optimum filtration.

High energy consumption for membrane presses:

- Membrane filter presses, which exert additional pressure on the filter cake, have a higher energy requirement.

Use of chemicals to support filtration:

- In some cases, flocculants or filtration aids are required to better bind the solids, which can increase operating costs.

Conclusion

The filter press is a central component of filtration technology in industrial wastewater treatment. Thanks to its flexible design and the ability to adapt to different requirements, it represents an efficient solution for dewatering and solids separation. The careful selection of filter cloths and optimized process control are decisive for the economic efficiency and sustainability of wastewater treatment and make filter presses an indispensable tool for dewatering sludge from wastewater treatment.

For further information on our products, please feel free to contact us at any time!