A fermenter is a technical system for carrying out biological processes in which microorganisms, enzymes or cells break down, convert or synthesize substances. In industrial water and wastewater treatment, fermenters are mainly used for the anaerobic treatment of organically contaminated wastewater. They are used to stabilize sludge or to produce biogas from organic substrates.

Technical background

The fermenter creates optimum conditions for the microorganisms that carry out the biological decomposition. These conditions include

- Temperature control: Mesophilic (30-40 °C) or thermophilic (50-60 °C) fermentation.

- pH control: Mostly neutral (6.5-7.5) to maximize the activity of microorganisms.

- Mixing systems: To distribute the substrates evenly and ensure contact with the microorganisms.

- Gas management: extraction and storage of biogas (methane and carbon dioxide).

Structure and components

A typical fermenter consists of the following main components:

- Reaction tanks: Made of steel or concrete, often thermally insulated.

- Agitators or gassing systems: For mixing the substrate and avoiding deposits.

- Heating systems: For temperature control.

- Measurement and control technology: For pH, temperature, redox potential and gas yield.

- Gas treatment: For desulphurization and drying of the biogas produced.

Application in waste water treatment

Fermenters are used in various industrial sectors:

Anaerobic wastewater treatmentOrganic substances are converted to biogas in the absence of oxygen. Examples:

- Food industry: Degradation of organic residues from dairies or breweries.

- Chemical industry: Treatment of highly contaminated wastewater with chemical oxygen demand (COD) in the range of 10,000 mg/l and more.

Sludge stabilization: For reducing the volume and degassing sewage sludge in sewage treatment plants.

Biogas plants: Use of agricultural substrates (liquid manure, plant residues) and organic waste to generate energy.

Table of contents

Types of fermenters

Typical reactors for anaerobic processes are:

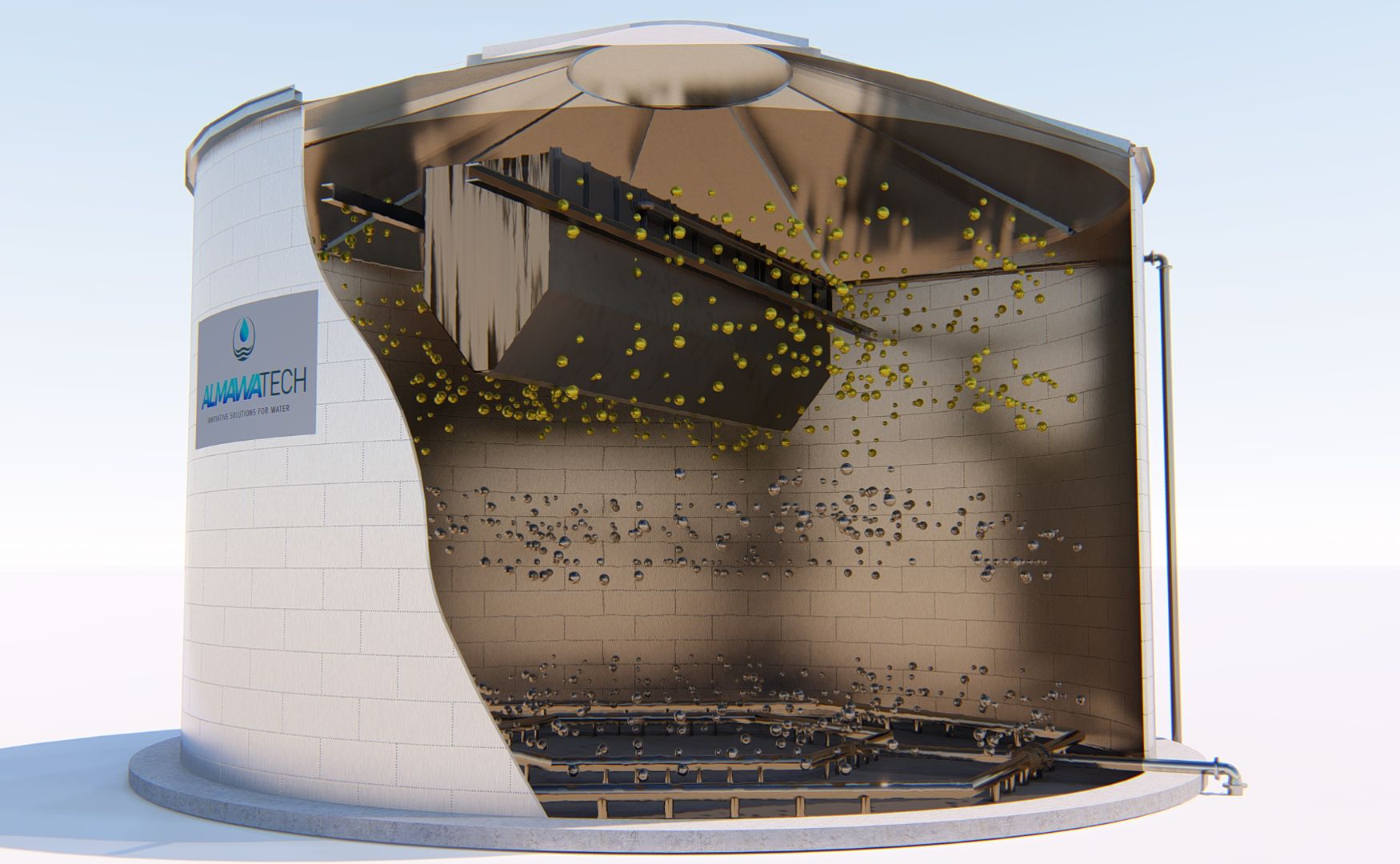

UASB reactors (Upflow Anaerobic Sludge Blanket):

The UASB reactor (Upflow Anaerobic Sludge Blanket) is an anaerobic reactor technology characterized by efficient wastewater treatment and biogas production. The wastewater flows in a counter-current principle from the bottom to the top of the reactor, where it meets a sludge layer consisting of granulated anaerobic microorganisms. These microorganisms break down the organic substances in the wastewater under anaerobic conditions and produce biogas, which consists mainly of methane and carbon dioxide.

Technical specifications:

- Flow direction: From bottom to top (upflow)

- Hydraulic dwell time: Typically between 6 and 12 hours

- Organic loading rate: Up to 10 kg COD/m³-d

- Temperature range: Can be operated in both mesophilic (30-40°C) and thermophilic (50-60°C) areas

- Gas production: 0.25 to 0.35 m³ of biogas per kg of degraded COD

Photo: Schematic representation of our ALMA BIO UASB reactor

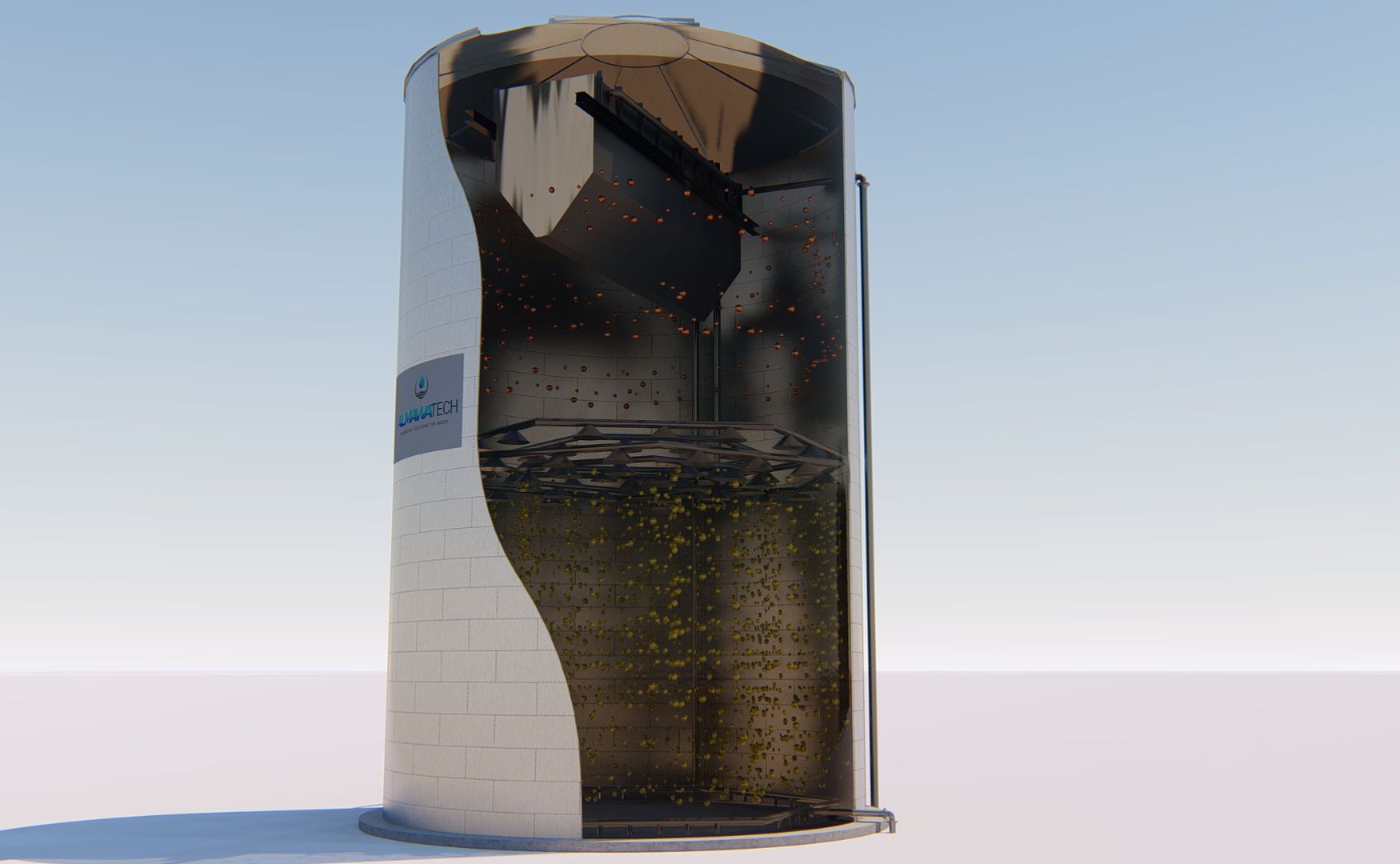

EGSB reactors (Expanded Granular Sludge Bed):

The EGSB reactor (Expanded Granular Sludge Bed) is a further development of the UASB reactor and is characterized by a higher flow rate and better mixing. In the EGSB reactor, the wastewater is fed through the granulated sludge layer at a higher speed, which reduces the hydraulic retention time and increases the organic load. This improved fluid circulation and expansion of the sludge bed makes the reactor more efficient, especially for wastewater with a very high organic load.

Technical specifications:

- Flow direction: From bottom to top, similar to the UASB reactor, but with a higher flow velocity.

- Hydraulic retention time: Typically between 1 and 6 hours, depending on the wastewater composition.

- Organic loading rate: Up to 30 kg COD/m³-d

- Reactor height: EGSB reactors are typically higher than UASB reactors, which leads to better separation of sludge and wastewater.

- Gas production: Similar to the UASB reactor, with a gas production of around 0.3 to 0.35 m³ of biogas per kg of degraded COD.

Photo: Schematic representation of our ALMA BHU BIO EGSB reactor

Gas mixing reactors:

- In our ALMA BHU GMR (gas mixing reactor), the wastewater is treated efficiently under anaerobic conditions, whereby the reactor was specially developed for wastewater with high calcium concentrations. The advanced gas mixing technology of the ALMA BHU GMR ensures optimum mixing of the reaction gases in the wastewater, which greatly improves the biodegradation and precipitation of calcium.The reactor offers a particularly efficient solution for wastewater that is difficult to treat due to its high calcium content. It not only reduces the organic load of the wastewater, but also enables targeted calcium precipitation, which prevents deposits in downstream systems. This ensures stable operation and significantly reduces maintenance costs. The ALMA BHU GMR is therefore ideal for industrial applications where high calcium concentrations in wastewater are a key challenge.

Photo: Photos of our anaerobic gas mixing reactor ALMA BHU GMR

Advantages of using fermenters

- High degradation capacity: digesters can degrade up to 80-90 % of the organic load.

- Energy generation: The biogas produced can be used to cover your own energy requirements or to feed into the gas grid.

- Reduction of sludge volume: Saves costs in sludge treatment and disposal.

Challenges

- Complex control: Process control requires precise regulation of parameters such as temperature, pH value and substrate supply.

- Sensitivity of microorganisms: Disturbances in the substrate or environmental parameters can lead to process instabilities.

- Corrosion: The aggressive nature of biogas requires the use of corrosion-resistant materials.

Conclusion

Fermenters are essential components for sustainable wastewater treatment and energy generation. With innovative solutions such as the ALMA BHU GMR, ALMA BHU EGSB and ALMA BIO UASB, ALMAWATECH supports industries in achieving their environmental goals and working economically at the same time.

For further information on our products, please feel free to contact us at any time!