Deammonification is an innovative biological process for removing nitrogen from wastewater, which is used particularly in industrial wastewater treatment where there are high nitrogen concentrations and a low carbon content. In contrast to conventional processes, deammonification combines two biological processes - partial nitritation and the anammox reaction - in one step, which reduces the use of external carbon sources. This makes deammonification a particularly energy- and cost-efficient process.

Table of contents

Technical background of deammonification

In conventional nitrification and denitrification processes, ammonium (NH₄⁺) is first completely oxidized to nitrate (NO₃-) and then reduced to gaseous nitrogen (N₂) by using an external carbon source (e.g. methanol). This process requires a high oxygen input and external carbon sources, which leads to high operating costs.

Deammonification relies on a combination of the following two processes:

Partial nitritation: Part of the ammonium is oxidized to nitrite (NO₂-) under aerobic conditions by ammonium oxidizers (AOB - ammonium-oxidizing bacteria). This only requires around 60% of the oxygen compared to complete nitrification.

Anammox process: Under anaerobic conditions, special bacteria, the so-called anammox bacteria (anaerobic ammonium oxidizers), use both the remaining ammonium and the nitrite produced to form gaseous nitrogen (N₂). This happens without the use of external carbon sources.

By combining these two processes, not only is the oxygen requirement reduced by around 60 %, but the need for external carbon sources is also reduced by up to 100 %, resulting in significant energy savings and lower operating costs.

Photo: Denitrification and nitrification basin for industrial wastewater from the food industry in Chile, ALMA BHU BIO plant

Areas of application in practice

Deammonification is particularly suitable for wastewater with:

- High ammonium content (e.g. sludge water from sewage treatment plants, industrial wastewater)

- Low organic carbon content (as no additional carbon source is required)

Typical industries in which deammonification is used are:

- Food and beverage industry

- Chemical and petrochemical plants

- Sludge treatment plants in municipal sewage treatment plants

Advantages of deammonification

- Reduced energy consumption: The lower oxygen requirement and the absence of external carbon sources significantly reduce operating costs.

- Less sludge production: Compared to conventional biological processes, deammonification results in less excess sludge production, which reduces disposal costs.

- Compact systems: As the process can be carried out in a reactor, deammonification systems require less space and are easier to operate.

- Sustainability: The Anammox process uses existing nitrogen compounds, which minimizes the use of resources and improves the ecological footprint of the process.

Products from ALMAWATECH

ALMAWATECH relies on biological wastewater treatment with innovative technologies to efficiently remove nitrogen while minimizing energy and resource consumption. Two of our solutions that are suitable for deammonification are the ALMA BioFil Compact and ALMA BHU BAF.

ALMA BioFil Compact: This compact biofiltration system is ideal for wastewater flows of up to 100 m³/h. It is ideal for the pre-treatment of wastewater prior to membrane filtration, such as reverse osmosis. Through biological pre-treatment, the ALMA BioFil Compact reduces the residual load of organic substances and minimizes biofouling in downstream membrane systems. Deammonification can be integrated here as a sub-process in order to reduce the nitrogen content in the wastewater.

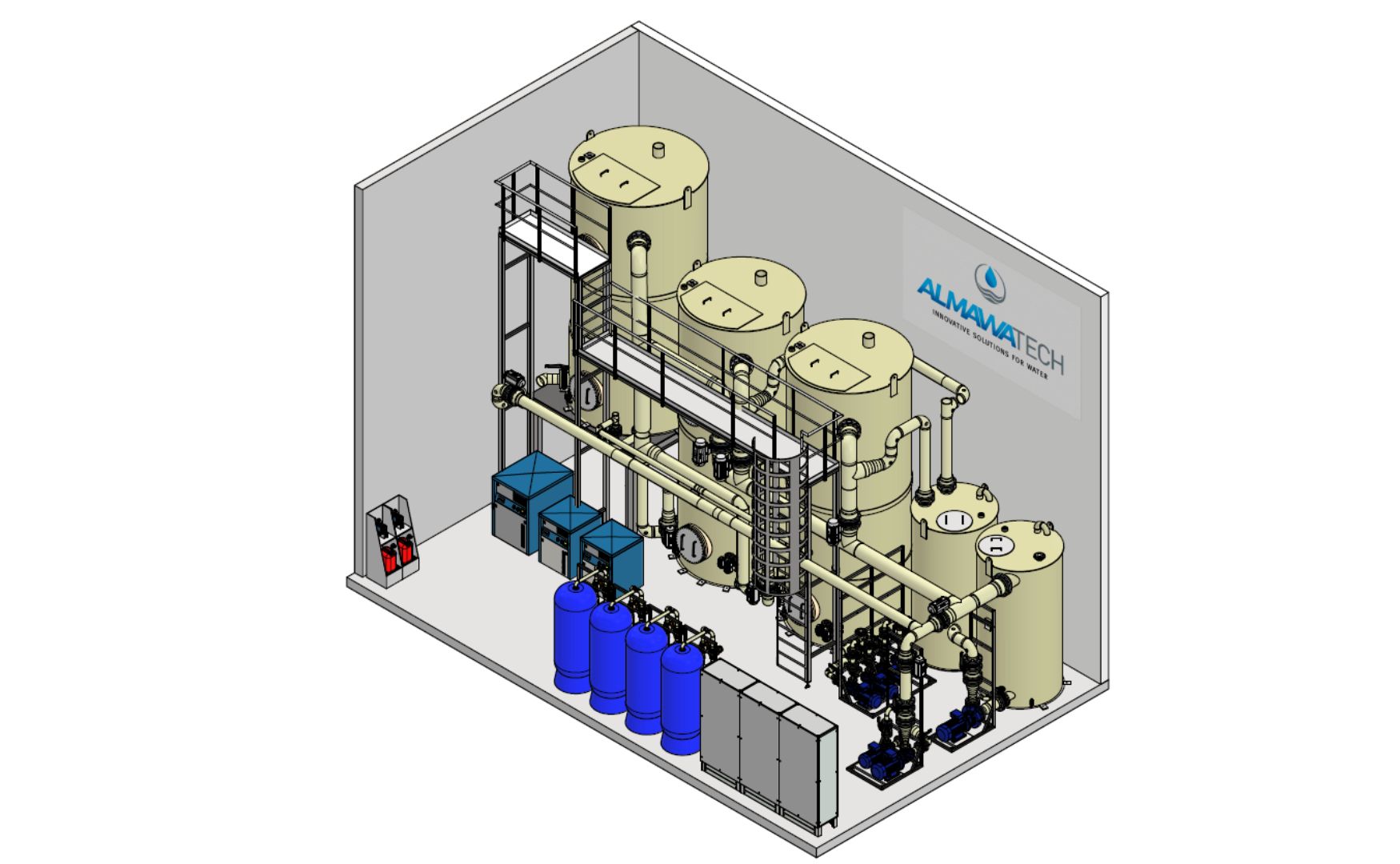

Photo: 3D design of our biologically activated ALMA BioFil Compact filtration system

ALMA BHU BAF

This large-scale biofiltration system is designed for water flows of up to 1,000 m³/h and is usually built in concrete. The ALMA BHU BAF is suitable for denitrification and nitrification and can also be adapted for deammonification if configured accordingly. In industrial plants that require efficient nitrogen removal, this technology can significantly reduce energy consumption and improve the economic efficiency of wastewater treatment.

Photo: Photo of our biologically activated filtration, a combination process of mechanical cleaning and biodegradation(ALMA BHU BAF)

Conclusion

Deammonification is an innovative and efficient method of nitrogen removal that is particularly suitable for wastewater with a high ammonium content and low organic loads. With products such as the ALMA BioFil Compact and the ALMA BHU BAF ALMAWATECH offers high-performance solutions for integrating this technology into industrial wastewater treatment processes. Thanks to the energy savings and reduced use of resources, deammonification is a sustainable solution for many industries.