A biofilter is a technical system that is used for the biological purification of water or air. It is based on the activity of microorganisms that break down pollutants or convert them into harmless compounds. Biofilters are widely used in industrial water and wastewater treatment, where they break down organic impurities and nitrogen compounds, as well as in exhaust air purification, for example to remove odorous substances and VOCs (volatile organic compounds).

Table of contents

Technical background of biofiltration

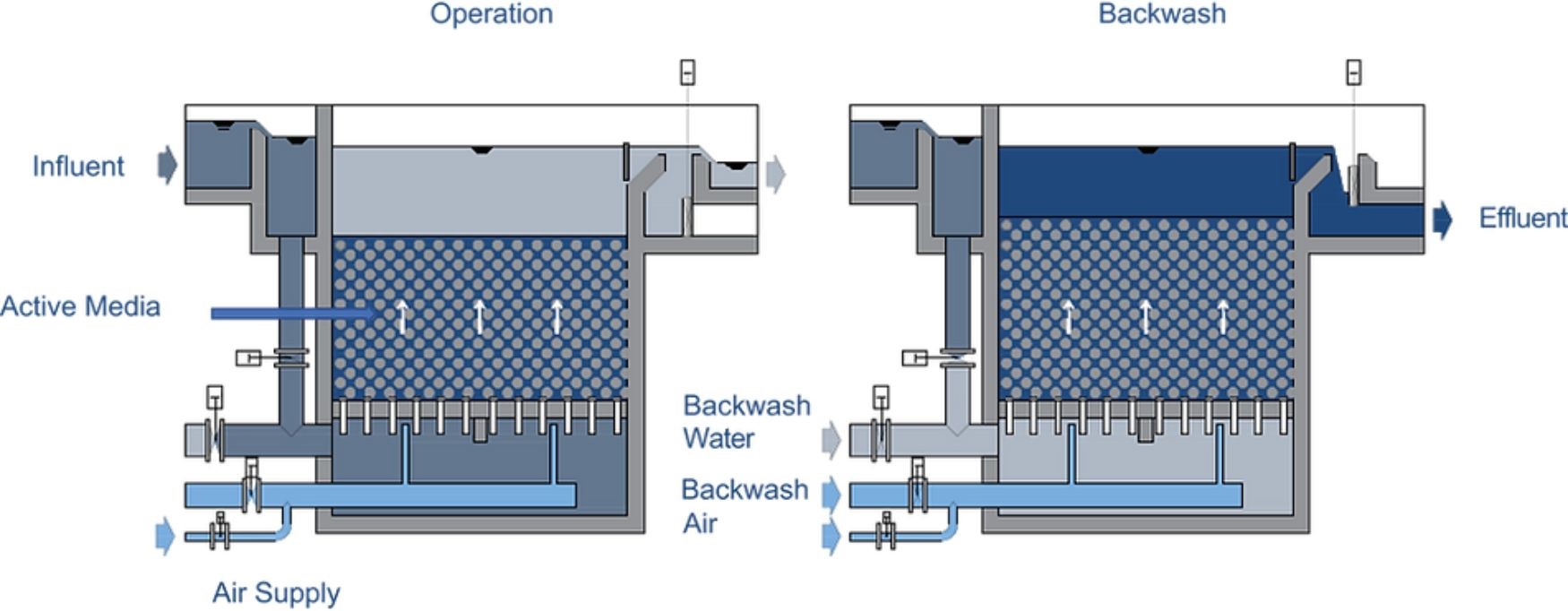

In biofiltration, the water or wastewater flows through a medium filled with growth media (filter materials), which provides a large surface area for the growth of microorganisms. These microorganisms settle on the growth media and form a biofilm that breaks down the organic substances in the water. The process takes place in aerobic or anoxic conditions, depending on whether oxygen is available or not. Typical biofiltrative processes include

Carbon elimination: Organic compounds, such as hydrocarbons and proteins, are used by the microorganisms as a food source and converted into carbon dioxide (CO₂) and water.

Denitrification and nitrification: Biofiltration is also able to remove nitrogen compounds. During nitrification, ammonium ions (NH₄⁺) are oxidized to nitrite (NO₂-) and then to nitrate (NO₃-). In the subsequent denitrification step, nitrate is reduced to nitrogen gas (N₂) by specialized bacteria under anoxic conditions and thus removed from the water cycle.

Application in industrial water and wastewater treatment

In industrial practice, biofiltration is used in particular for the treatment of wastewater with high organic loads and for water treatment. It plays a decisive role as pre-treatment for reverse osmosis systemsto efficiently remove residual organic loads and nitrogen compounds. This is particularly important in the context of water recycling (Water ReUse) and the production of process water from wastewater.

A typical example of the use of biofiltration is vapor condensates from the food industry (especially dairies), which have to be treated before further processing due to their high residual organic content. Biofiltration ensures that the organic compounds are removed before membrane filtration (e.g. reverse osmosis), which reduces biofouling of the membranes and extends the service life of the membrane systems.

Photo: ALMA BHU BiosS-Treat reverse osmosis system for recovering process water from wastewater

ALMAWATECH biofiltration products: ALMA BHU BAF and ALMA BioFil Compact

ALMAWATECH offers two specific biofiltration solutions that can be used depending on the water or wastewater flow and application:

1. ALMA BHU BAF

The ALMA BHU BAF (Biologically Activated Filtration) is designed for water flows of up to 1,000 m³/h and is realized in concrete construction. This large-scale biofiltration technology is ideal for industrial processes with high water flows where continuous and efficient removal of organic substances is required. Typical areas of application are large production plants or process chains in which the water is to be treated for the reuse cycle.

Photo: Biofiltration ALMA BHU BAF, process diagram

2 ALMA BioFil Compact

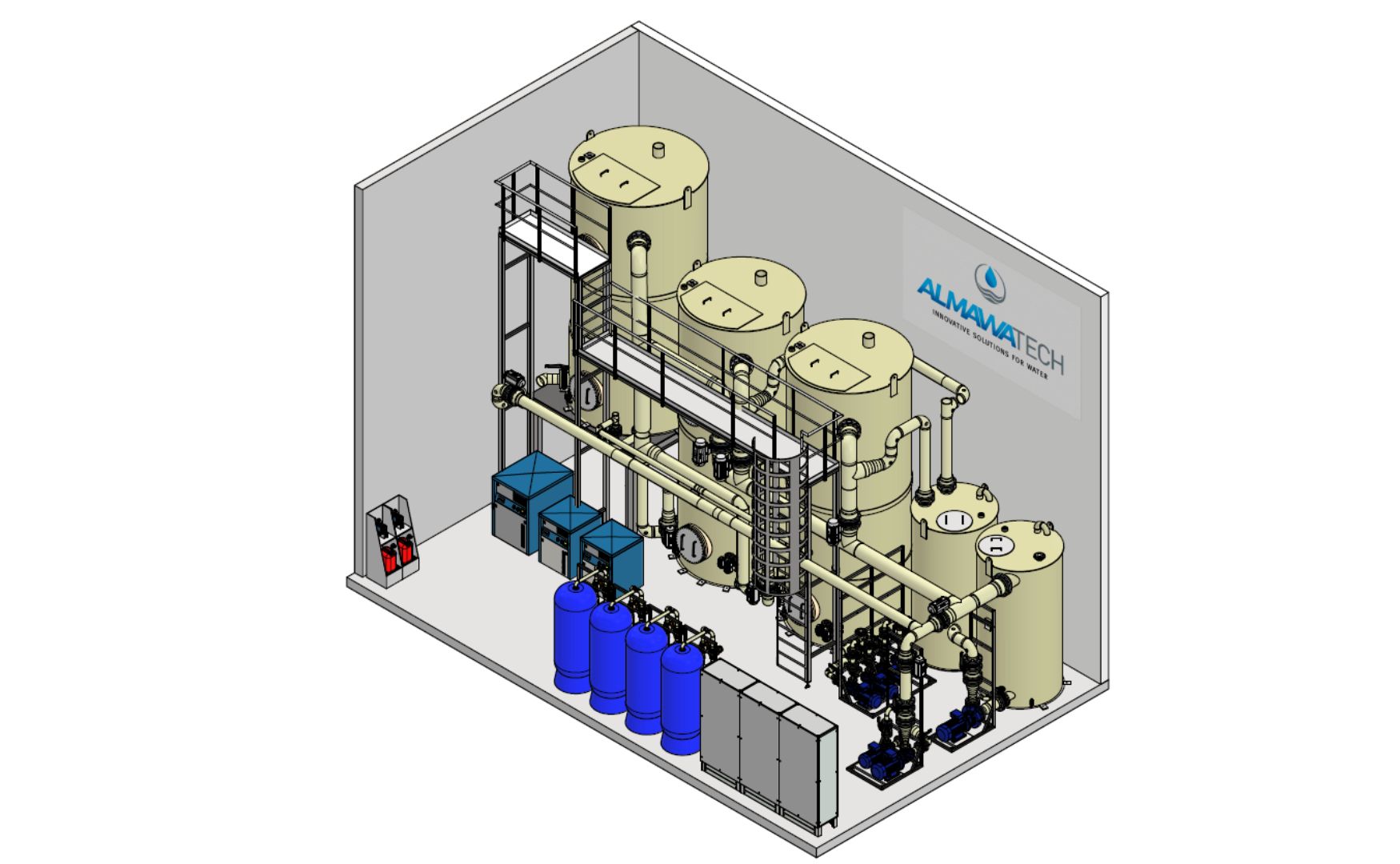

The ALMA BioFil Compact is a compact solution for wastewater flows of up to 100 m³/h. This system is particularly suitable for applications where smaller volumes of water need to be treated, such as in smaller industrial plants or for specific process wastewater flows. Thanks to its compact design, it can be easily integrated into existing systems and offers a cost-effective solution for the pre-treatment of wastewater for reverse osmosis systems.

Photo: ALMA BioFil Compact biofiltration system, 3D design

Both systems are based on the use of specially prepared clay beads or other growing media with a high surface area that harbor both aerobic and anoxic microorganisms. This allows efficient biological treatment and the simultaneous implementation of nitrification and denitrification.

Biofiltration as pre-treatment for reverse osmosis systems

A key area of application for biofiltration, particularly for ALMAWATECH solutions, is pre-treatment for reverse osmosis systems as part of water recycling processes. Reverse osmosis systems depend on the water to be treated having the lowest possible residual organic load in order to avoid biofouling and clogging of the membranes. Biofiltration plays a decisive role here by reducing the organic substances and nutrients in the water.

Advantages of biofiltration as pre-treatment:

Effective reduction of organic substances: Biofiltration ensures a significant reduction in biodegradable organic substances and thus reduces biofouling in downstream membrane processes.

Cost-efficient solution: By using biofiltration as pre-treatment, the operating costs of reverse osmosis systems can be significantly reduced, as the chemical consumption for membrane cleaning and the frequency of membrane replacement are reduced.

Extension of membrane service life: By breaking down organic residues and nitrogen compounds at an early stage, biofiltration extends the service life of the membranes and minimizes the need for expensive maintenance measures.

Optimization of water recycling: The pre-treatment of waste water, such as vapour condensates, enables efficient recovery of water and helps to meet the water quality requirements for the process water cycle.

Denitrification and nitrification in biofiltration

In many industrial applications, particularly in the field of wastewater treatment, it is necessary to remove nitrogen compounds. This is achieved by the combination of nitrification (conversion of ammonium to nitrate) and denitrification (reduction of nitrate to nitrogen gas) described above. These processes can be specifically controlled in biofiltration by creating specific aerobic and anoxic zones in the biofilter that harbor the corresponding microorganisms.

Advantages of denitrification and nitrification:

Effective nitrogen removal: Nitrogen is efficiently removed through targeted denitrification and nitrification, which is particularly important in nutrient-contaminated wastewater.

Environmental protection: The removal of nitrogen reduces the risk of eutrophication in water bodies, as excess nutrients in the water can lead to excessive algae growth.

Conclusion

The biofiltration is a highly efficient and sustainable method of biological water and wastewater treatment. With products such as the ALMA BHU BAF for large water flows and the ALMA BioFil Compact for smaller wastewater volumes, ALMAWATECH offers flexible solutions that can be integrated into various industrial applications. Biofiltration plays a key role, particularly as pre-treatment for reverse osmosis systems for water recycling, as it enables cost-efficient reduction of organic substances and nitrogen compounds and significantly extends the service life of the membranes.