In industrial water and wastewater treatment, chemicals such as sodium hydroxide (NaOH) for pH value regulation or iron(III) chloride for the precipitation of phosphates and heavy metals are used on a daily basis. The storage of these chemicals requires special safety precautions and is subject to strict legal requirements.

The protection of our waters is at the heart of German environmental law. Anyone working with substances hazardous to water - from small businesses to large-scale industry - must comply with strict legal requirements. This is regulated by the Water Resources Act (WHG) and the Ordinance on Installations Handling Substances Hazardous to Water (AwSV). They ensure that substances hazardous to water may only be stored and handled in facilities that are designed in such a way that no adverse changes to water bodies can occur.

Table of contents

What does WHG-compliant storage tank mean?

WHG-compliant storage facilities must be designed in such a way that even in the event of an accident (e.g. leakage or overfilling) no water-polluting substances can enter the soil or water. In concrete terms, this means

- The containers must be leak-proof, resistant to chemicals and mechanically stable

- A WHG-certified drip tray with an appropriate volume must be available (at least the volume of the largest individual container)

- Leakage probes and overfill protection are mandatory

- Level indicators must be WHG-tested and tamper-proof

- For outdoor installation, additional weather protection, insulation and frost protection are required

A storage tank may only be operated as WHG-compliant if all these requirements are met.

Photo: Delivery of one of our WHG-compliant storage tanks with integrated dosing station

WHG and AwSV: Legal requirements at a glance

According to the German Federal Water Act (WHG) and the Ordinance on Installations for Handling Substances Hazardous to Water (AwSV), strict requirements apply to the handling of substances hazardous to water. Here are the key points and differences between the activities:

General requirements according to WHG and AwSV

Protection principle (§ 62 WHG): Installations must be designed in such a way that there is no risk of adverse changes to the water body. This includes construction, operation, maintenance and decommissioning.

Technical standards: Compliance with the generally recognized rules of technology (e.g. DIN standards, TRwS).

Classification of substances: Substances are to be classified in water hazard classes (WGK 1-3) (WGK 3 = highly hazardous to water).

- WGK 1: slightly hazardous to water (e.g. acetic acid, caustic soda)

- WGK 2: clearly hazardous to water (e.g. heating oil)

- WGK 3: highly hazardous to water (e.g. waste oil, benzene)

Documentation and monitoring: Obligation to be inspected by experts, preparation of operating logs and reporting of leaks.

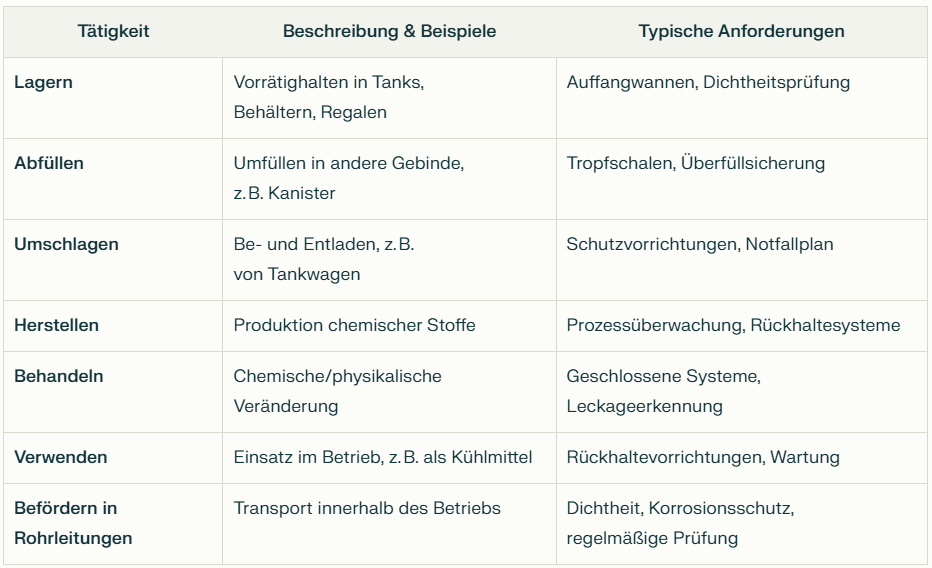

Differences between the activities

The AwSV distinguishes between LAU facilities (storage, filling, handling) and HBV facilities (production, treatment, use) as well as in-house transportation. The requirements vary depending on the activity and WGK of the substances:

Storage (storage)

- Definition: Holding of substances in containers, tanks or storage rooms.

- Examples: Heating oil tanks, chemical storage.

- Requirements:

- Secondary barrier (drip pans) for WGK 2/3.

- Regular leak tests.

Filling

- Definition: Transferring substances (e.g. from tanker trucks into containers).

- Risk: splashes, leaks during transfer.

- Measures:

- Drip trays under filling points.

- Trained staff and emergency plan.

Envelope

- Definition: Loading and unloading of transport containers (e.g. rail tank wagons).

- Special feature: Often with increased risk due to frequent movements.

Manufacture/treatment

- Definition: Production or chemical/physical processing of substances.

- Examples: Chemical plants, paint shops.

- Requirements:

- Closed systems for volatile substances (WGK 3).

- Process monitoring and leakage detection.

Use

- Definition: Use of substances in work processes (e.g. cooling lubricants).

- Risk: Continuous contact with substances hazardous to water.

- Measures:

- Restraint devices on machines.

- Regular maintenance.

Internal transportation (pipelines)

- Definition: Transportation of substances within the plant premises via pipelines.

- requirements (§ 62 WHG):

- Pipes must be leak-proof and corrosion-resistant.

- Regular inspection by experts.

- When exceeding the factory premises: Authorization required.

Summary of the different classifications according to AwSV

When does an external storage tank make economic sense?

IBC-based dosing stations are often sufficient in smaller systems or for low chemical consumption. However, as soon as larger quantities of neutralizing or precipitating agents are required on a regular basis, external storage tanks come into their own:

- Lower delivery costs per liter due to large-volume delivery by tank truck

- Less handling on site (no IBC exchange, no manual storage)

- Increased process reliability thanks to integrated safety devices

- Direct dosing from the storage tank without decanting

- Less space required for large stocks

From a daily consumption of around 200-250 liters per day, the investment in a WHG-compliant storage tank can be economically worthwhile.

ALMA storage containers: safe, intelligent and tried and tested

Our ALMA storage tanks are specially designed for industrial use with water-polluting substances - for example for storing and dosing caustic soda, ferric chloride or other process additives.

Key features of our systems

- WHG-compliant double-walled design made of chemical-resistant materials

- Drip tray with integrated leakage probe

- Insulation and heating for outdoor installation (e.g. winter operation)

- Climbing ladder with safety cage, platform and grating for roof access

- WHG-approved level indicator and overfill protection

- Tanker connection with secured filler neck

- Direct dosing from the storage tank into the process - without intermediate transfer

These storage tanks can be seamlessly integrated into our ALMA dosing stations and control systems, offering maximum safety, convenience and efficiency.

Conclusion

A WHG-compliant storage tank is not only a legal necessity, but a real gain for safety and efficiency in wastewater technology. Our ALMA solutions combine legal safety, technical quality and practical functionality - ideal for anyone who wants to rely on professional chemical storage.