The chemical treatment of steam boilers and boiler systems is crucial for their efficiency and longevity. It includes a range of measures to prevent deposits and corrosion, improve water quality and optimize overall operation. Below we explain the main chemicals and their use in boiler feed water treatment.

Table of contents

Aim of the chemical treatment of boiler feed water and steam boilers

Protection against corrosion

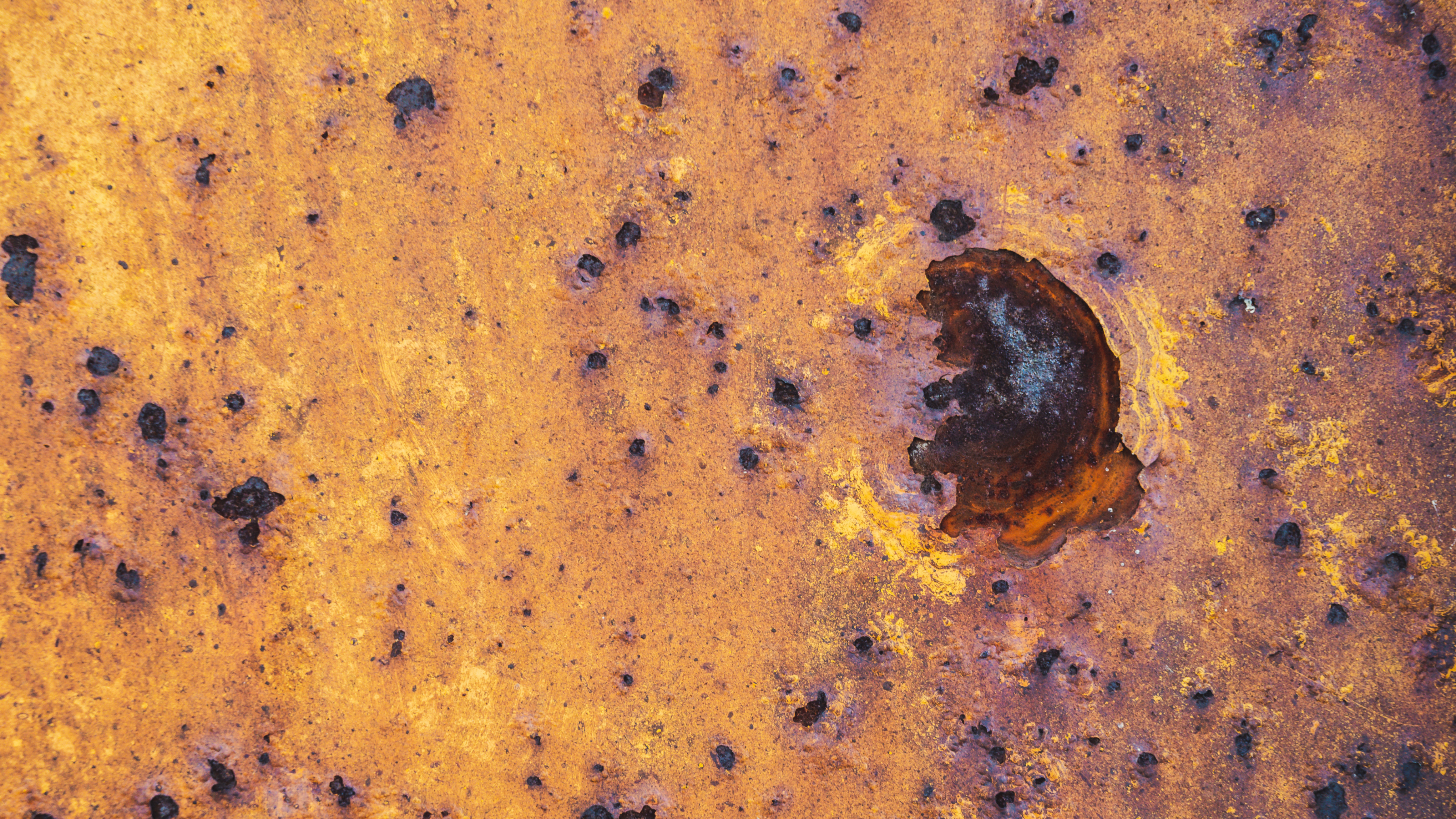

The main objective of chemical treatment of boiler feed water and steam boilers is to prevent corrosion. Corrosive elements such as oxygen and carbon dioxide can attack the metal surfaces of boilers and pipes and cause serious damage. By using oxygen binders and pH value regulators, the corrosion rate is significantly reduced, which extends the service life of the boiler system and avoids costly repairs.

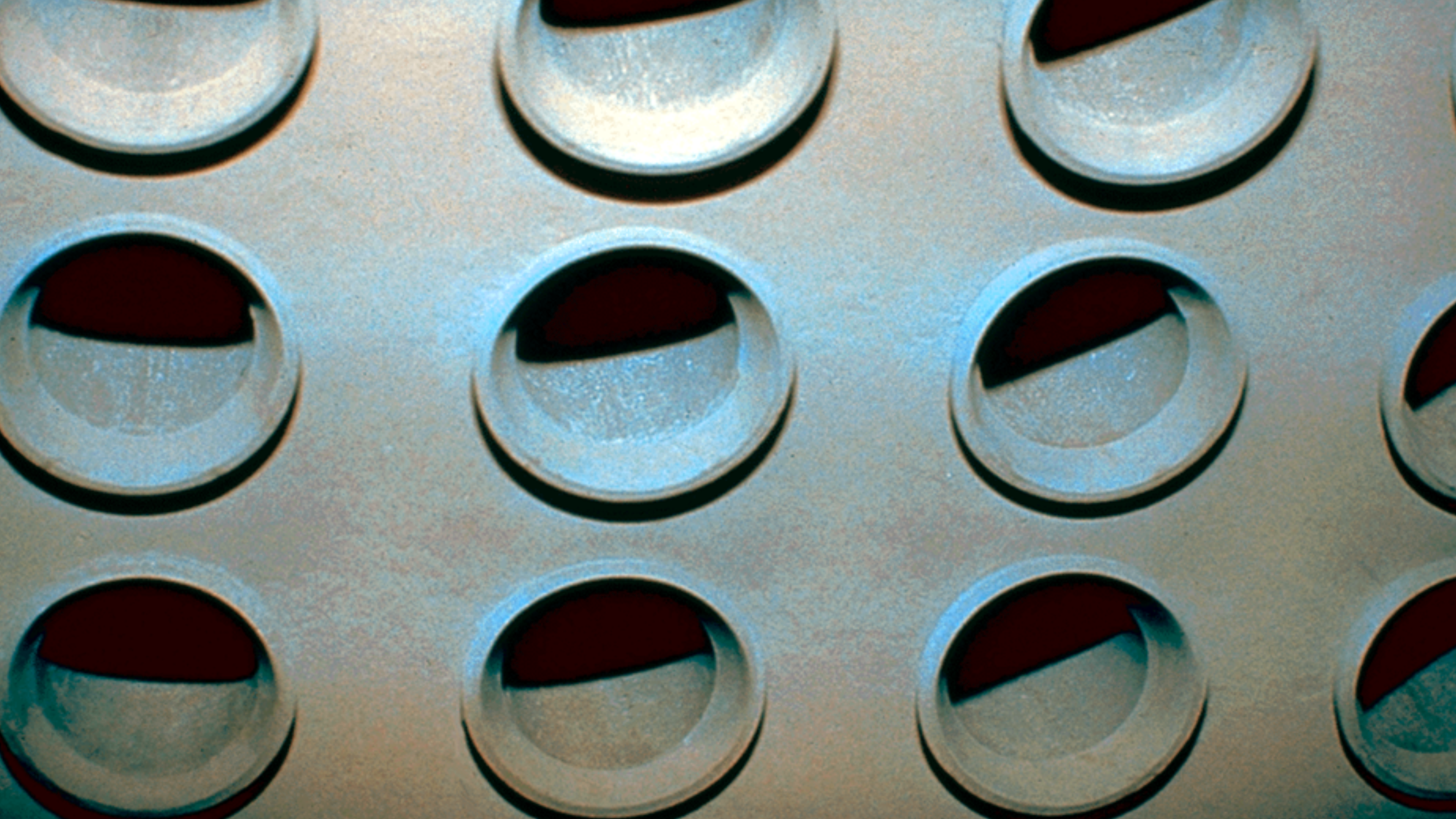

Photo: Severe oxygen corrosion in the steam boiler. The use of oxygen binding agents can prevent this problem.

Avoidance of deposits

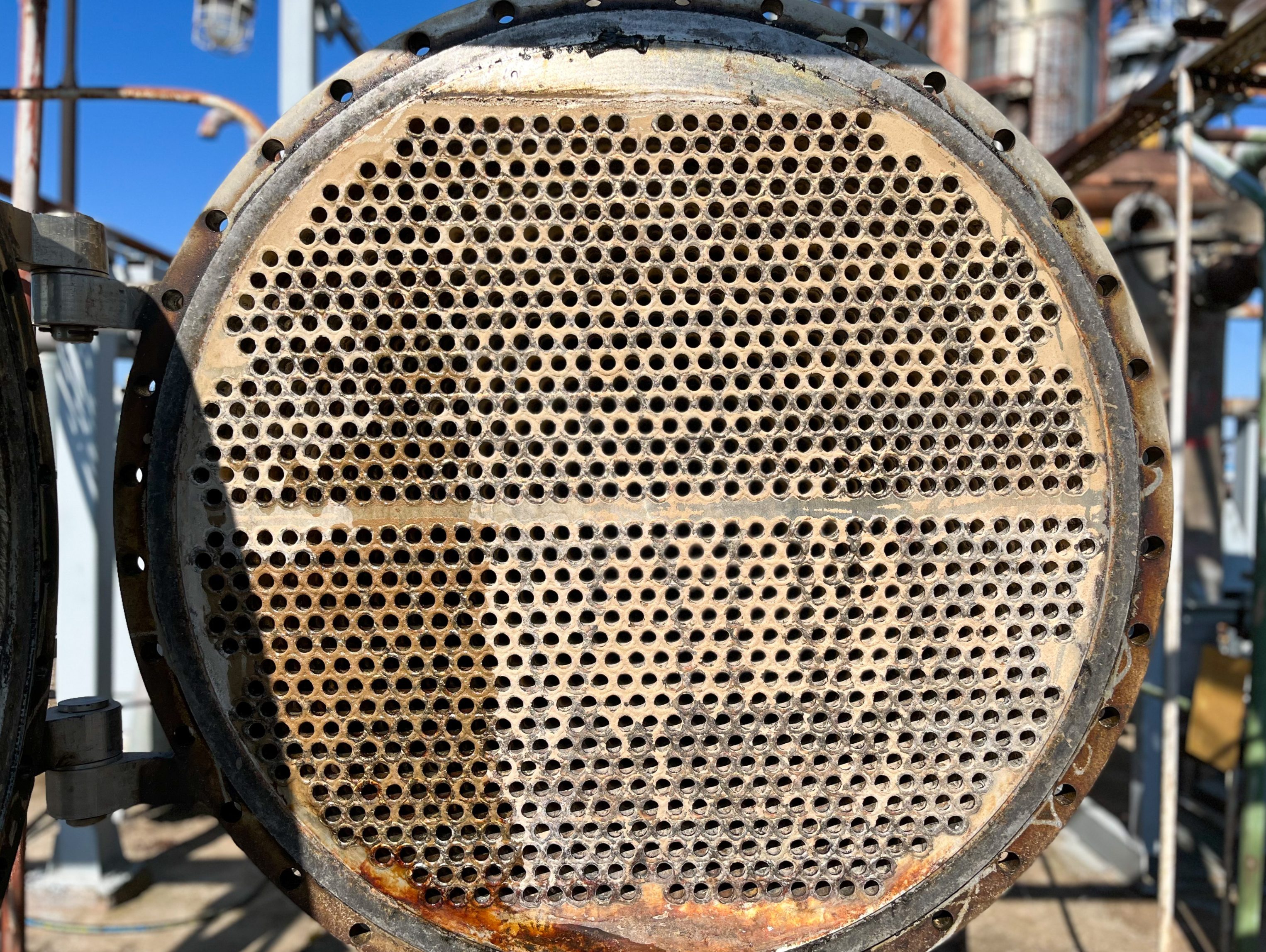

Deposits such as boiler scale and suspended particles can drastically reduce the efficiency of the boiler. They lead to poor heat transfer and, in the worst case, can lead to overheating and mechanical damage. Chemicals such as scale inhibitors and dispersants prevent the formation and deposition of such substances, keeping the efficiency of the boiler at an optimum level.

Photo: Steam boiler with corrosion damage and deposits

Optimization of water quality

The quality of the boiler feed water is crucial for the smooth operation of the boiler system. Chemical treatment ensures that the water has the right chemical properties. This includes controlling the residual hardness, regulating the pH value and removing dissolved gases. High-quality feed water leads to better performance and extended service life of the boiler components.

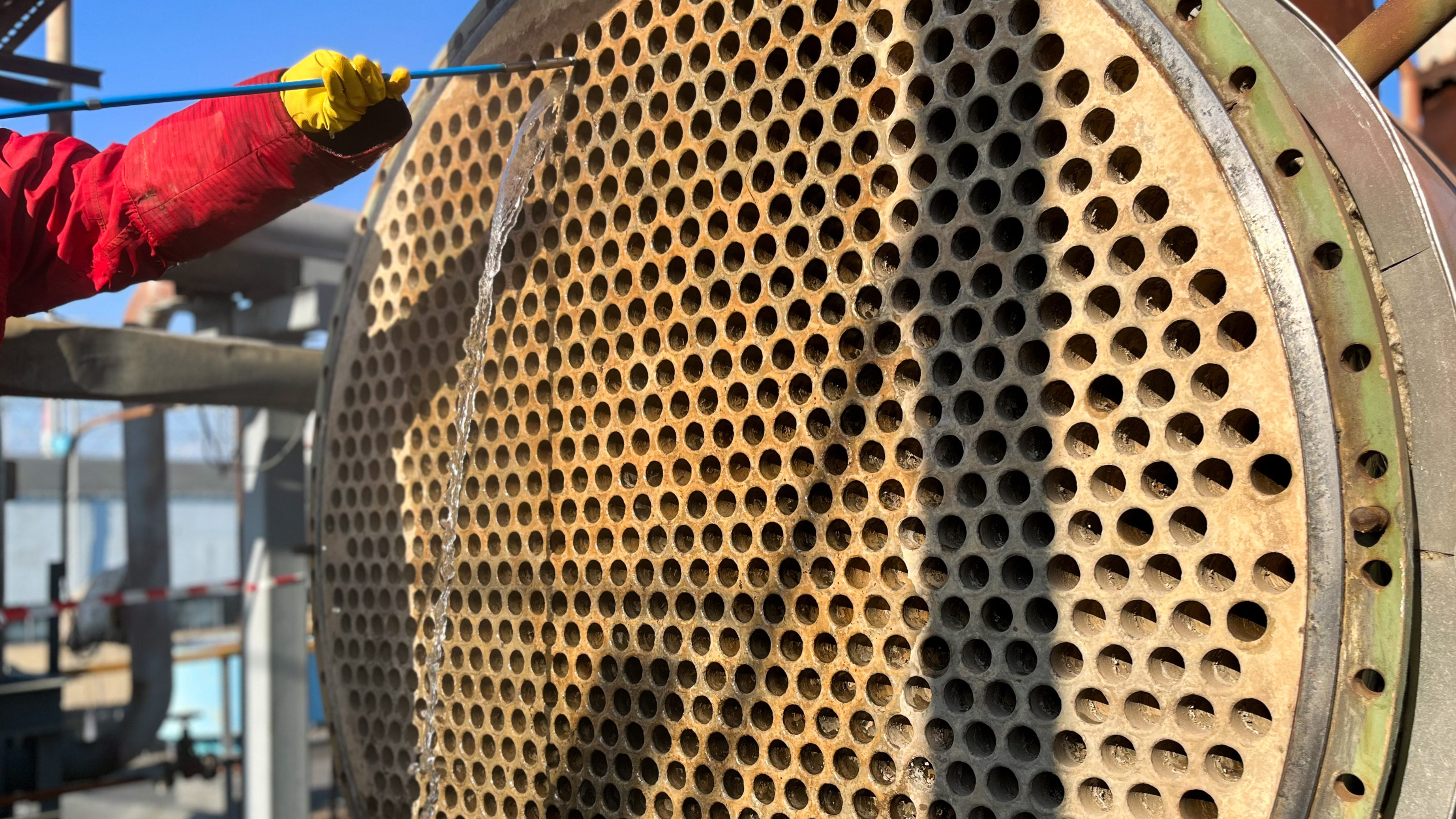

Increased efficiency

Another key aspect of chemical treatment is the increase in operating efficiency. Clean water without deposits and with an optimally adjusted pH value ensures excellent heat transfer. This leads to higher energy efficiency, lower operating costs and more sustainable operation of the boiler system.

Photo: Manual cleaning of a steam boiler to remove deposits in order to improve the deteriorated system efficiency. Extensive cleaning could have been avoided by adding auxiliary agents.

Avoidance of operational failures

Unforeseen operational failures can cause considerable economic losses. Chemical treatment of the boiler feed water and steam boilers minimizes the risk of malfunctions and breakdowns. Regular monitoring and adjustment of the chemical supply help to ensure that the system runs stably and reliably.

Photo: Leaking pipe due to corrosion.

Compliance with legal requirements

Compliance with legal regulations and industry standards is another objective of chemical water treatment. Many standards prescribe specific water quality parameters that must be met through appropriate chemical treatment programs. This not only helps to avoid fines and legal problems, but also ensures that the plant is operated in a safe and environmentally friendly manner.

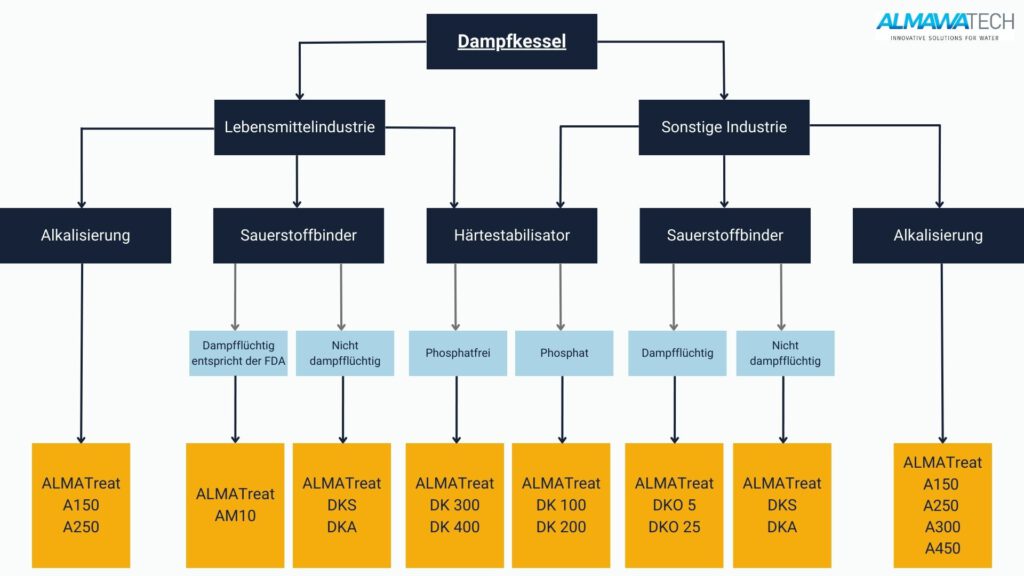

The different product groups for the treatment of feed water

Photo: Here you will find a rough overview of our operating resources for boiler feed water as well as an orientation guide for subdividing the product groups according to application and task.

Alkalizing agent

Alkalizing agents are essential to raise and stabilize the pH value of the boiler water. A slightly alkaline pH value is important to reduce corrosion and maintain the efficiency of the boiler. The p-value of the boiler water, also known as acid capacity KS 8.2, plays a central role here. Alkalizing agents can either be steam-volatile, whereby they also alkalize the steam and condensate network, or non-steam-volatile, whereby they remain in the water. These agents can be dosed individually or in combination with other products to achieve optimum results.

Oxygen binder

Oxygen binders are usually indispensable for the feed water, as degassing alone is often not sufficient to ensure adequate protection. Oxygen andCO2 are corrosive gases that can endanger the boiler. Oxygen binders reduce the amount of dissolved oxygen in the boiler feed water and thus protect various metal surfaces from corrosion through passivation. The exact dosage depends on the type of agent and the oxygen content. It is important that there is a surplus of the oxygen binding agent in the water in order to compensate for fluctuations in the oxygen input.

Photo: Thin-film passivated water pipes of a water pipe boiler to protect against deposits and corrosion.

Scale counteractant / dispersant

Scale inhibitors and dispersants prevent deposits such as scale (limescale) or iron compounds (corrosion residues). Typical representatives of these agents include phosphates, phosphonates, complexing agents and polymers. These chemicals produce sludge in the presence of lime and prevent the solid caking of scale. The resulting sludge is removed from the boiler by blowdown to maintain the efficiency of the boiler and prevent deposits.

Photo: Irregular deposits of phosphate compounds can be seen in the vapor space. These can be avoided by using adapted dispersants.

Summary and objectives

The chemical treatment of steam boilers and boiler systems is a key factor in their efficient and trouble-free operation. Alkalizing agents, oxygen binders and boiler scale counteractants play a central role here. They ensure that the pH value remains stable, corrosion is avoided and deposits are prevented. The correct use of these chemicals can significantly increase the service life and efficiency of your steam boiler system.

Our aim is to make the operation of your steam boiler system as efficient and smooth as possible. Find out more about our comprehensive solutions and how they can help you maximize the performance and service life of your boiler systems. We will be happy to provide you with tailored advice and optimal dosing solutions.

Our ALMA AQUA product range - efficient operating fluids for boiler feed water and steam boilers

Free consultation appointments

Arrange an online consultation with our specialist for the treatment of steam boilers and boiler feed water: