The UV treatment is a physical process used in water and wastewater treatment for disinfection, oxidation and removal of organic compounds. In contrast to chemical processes such as chlorination or ozonation, UV treatment is purely physical and leaves no chemical residues. It is therefore particularly environmentally friendly and is used in drinking water treatment, process water treatment, wastewater treatment and for the reduction of TOC (Total Organic Carbon).

By using high-energy UV radiation, microorganisms can be inactivated, organic compounds oxidized and stubborn pollutants such as pharmaceuticals, pesticides and residual chemicals broken down. Advanced processes such as UV oxidation play a central role, especially in the reduction of difficult-to-degrade contaminants in water.

Table of contents

Basics of UV radiation

The effect of UV treatment is based on ultraviolet radiation, an energy-rich part of the electromagnetic spectrum with wavelengths between 100 and 400 nanometers (nm). UV radiation is divided into three categories:

- UV-A (315-400 nm): Acts mainly on organic molecules, but with low energy density.

- UV-B (280-315 nm): Medium energy density, harmful to living cells.

- UV-C (100-280 nm): Highest energy density, used for water treatment as it effectively inactivates microorganisms and breaks chemical bonds.

UV-C radiation is primarily used in water and wastewater technology, particularly at a wavelength of 254 nm, as this is optimal for the DNA inactivation of microorganisms and the oxidation of organic substances.

Technical applications of UV treatment

1. UV disinfection

UV disinfection is one of the most common applications of UV treatment and is used to inactivate microorganisms such as bacteria, viruses, protozoa and fungi.

Mechanism of action:

- UV-C radiation destroys the DNA/RNA structures of microorganisms by forming thymine dimers. This prevents the microorganisms from dividing and multiplying.

- Unlike chemical disinfectants, UV treatment does not leave behind any by-products such as chloramines or organic halogen compounds.

Areas of application:

- Drinking water treatment: Ensuring hygienic water quality.

- Process water treatment: germ reduction in the pharmaceutical and food industries.

- Cooling water systems: Prevention of microbial contamination and biofouling.

2. UV oxidation (Advanced Oxidation Processes, AOPs)

UV oxidation combines UV radiation with chemical oxidants such as hydrogen peroxide (H₂O₂) or ozone (O₃) to generate hydroxyl radicals (-OH), which are highly reactive and capable of oxidizing difficult-to-degrade pollutants.

Principle of action:

UV radiation splits H₂O₂ or O₃ into hydroxyl radicals.

These radicals attack organic molecules and break them down into smaller, less toxic compounds such as carbon dioxide (CO₂) and water (H₂O).

Application:

- Removal of micropollutants such as pesticides, pharmaceuticals and endocrine disruptors.

- Elimination of micropollutants and poorly degradable substances.

- Odor removal and color removal from water streams.

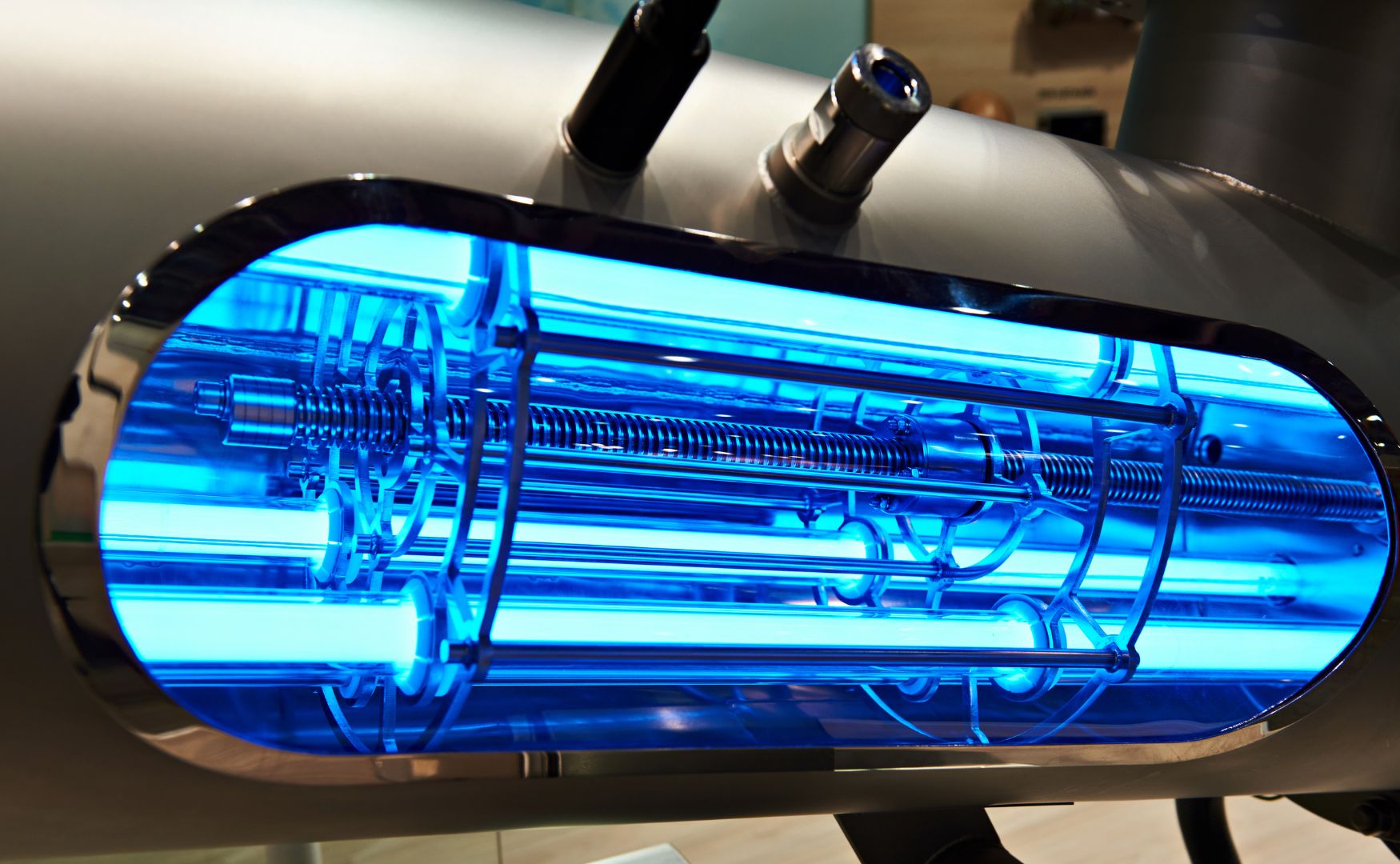

Photo: UV reactor with defined UV spectrum for the formation of highly radical hydroxyl radicals of the ALMA OXI UV

3. UV-TOC reduction

The reduction of total organic carbon (TOC) is particularly relevant in ultrapure water treatment and process water treatment. TOC stands for the total proportion of organic carbon compounds in water and is an indicator of water purity.

Mechanism of action:

- The UV radiation breaks down organic molecules into smaller fragments, which are then oxidized to carbon dioxide (CO₂) and water.

- The combination of UV radiation and hydrogen peroxide (UV/H₂O₂) is particularly effective here.

Areas of application:

- Electronics industry: Production of high-purity water for semiconductor processes.

- Pharmaceutical industry: production of ultrapure water for sterile applications.

- Laboratory water treatment: Removal of trace organics to ensure analytical accuracy.

Technical implementation of UV treatment

The technical implementation of UV treatment takes place in specially developed reactors that ensure uniform irradiation of the water.

Structure of a UV reactor

UV lamps:

- Low-pressure mercury lamps: Efficient at 254 nm, low energy density.

- Medium-pressure lamps: Higher output, broader spectrum, suitable for UV oxidation.

Reactor housing:

- Made of stainless steel to ensure corrosion resistance and maximum reflection of UV radiation.

Flow control:

- The flow rate is regulated so that the water is irradiated for a sufficiently long time to achieve the desired disinfection or oxidation performance.

Challenges in UV treatment

- Contamination of the lamps: Deposits on the lamp envelopes can impair the efficiency of the irradiation. Regular cleaning is necessary.

- Irradiation intensity: The intensity of the UV lamps decreases over time, so regular replacement is necessary.

- Water quality: Turbidity or high levels of suspended matter in the water can reduce UV permeability. Pre-filtration is often necessary.

Advantages of UV treatment

- Environmentally friendly: No chemical residues or by-products.

- Effectiveness: Highly effective against microorganisms and organic pollutants.

- Speed: Treatment takes place in real time, without long contact times.

- Versatility: Suitable for disinfection, oxidation and TOC reduction.

Conclusion

The UV treatment is a pioneering process in water and wastewater technology. Its ability to inactivate microorganisms and oxidize difficult-to-degrade pollutants without chemical additives makes it an environmentally friendly and efficient solution for a wide range of applications.

Especially in combination with hydrogen peroxide or ozone, the UV oxidation shows its strength in the removal of micropollutants and the reduction of TOC. With the right technical implementation and regular maintenance, UV technology offers a sustainable method for improving water quality in industrial and environmental applications.

For further information on our products, please feel free to contact us at any time!